Preparation method of functional organic fertilizer for soil restoration

A soil remediation and organic fertilizer technology, which is applied in the field of preparation of functional organic fertilizers for soil remediation, can solve problems such as agricultural economic losses, achieve the effects of enhancing moisture retention capacity, improving utilization rate, and relieving land tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

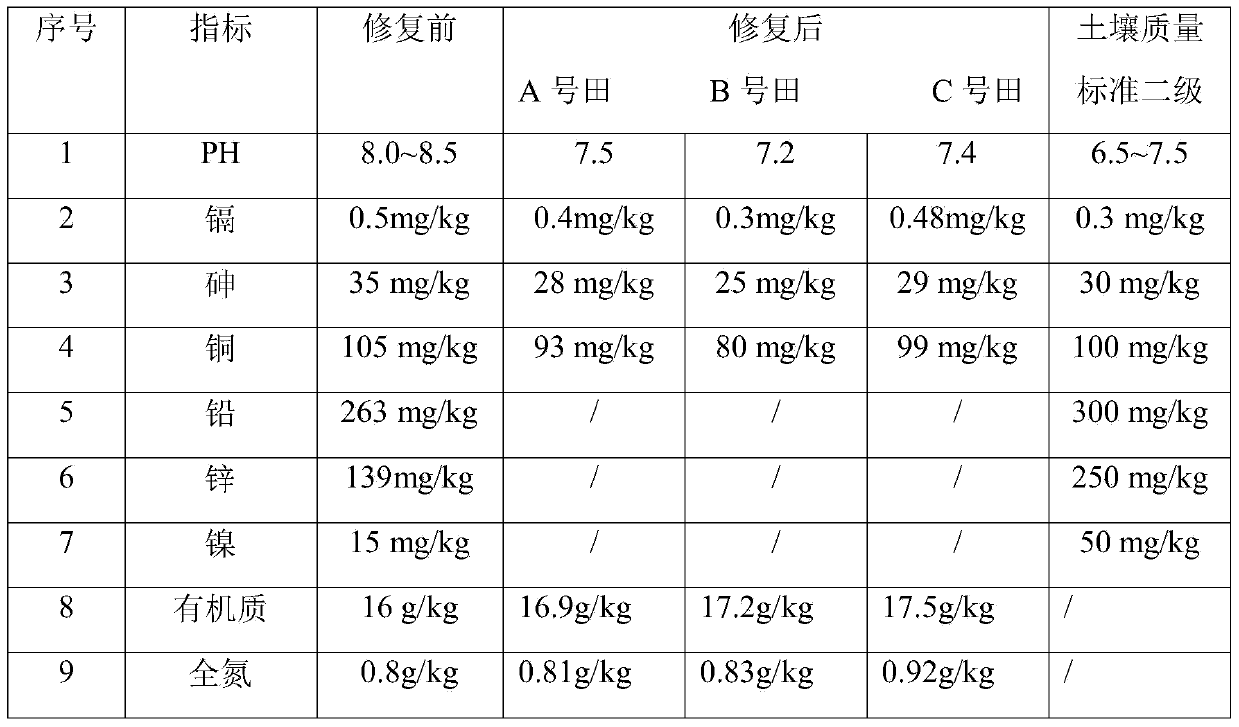

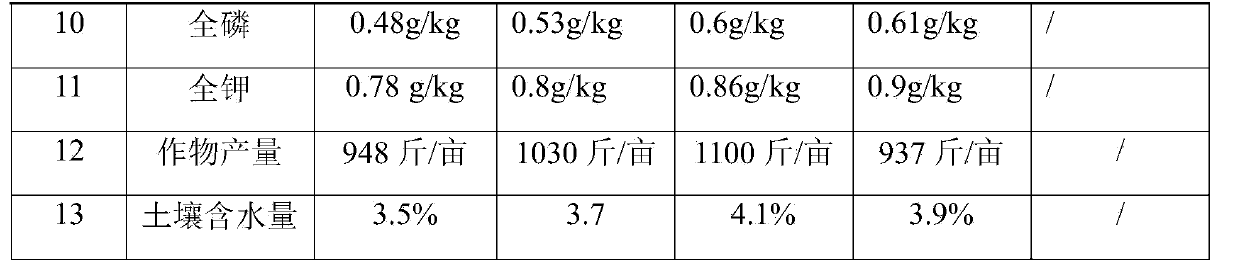

Image

Examples

Embodiment 1

[0037] 1. Preparation of functional organic fertilizer

[0038] After the straw is crushed, it is mixed with blue-green algae at a mass ratio of 1:10 to obtain a mixture, and then a biomass conversion compound bacterial agent with a mixture quality of 0.5‰ and a biomass conversion induction material with a mixture quality of 0.8‰ are added to the mixture, and mixed After uniformity, stack and ferment at room temperature for 10 days to obtain a semi-solid organic fertilizer. The semi-solid organic fertilizer obtained after fermentation is compounded and granulated with diatomite, biomass power plant carbon ash and heavy metal ion chelating agent at a mass ratio of 1000:50:50:1 to obtain a functional organic fertilizer for soil restoration.

[0039] Described biomass conversion compound microbial agent constitutes by mass percentage: 30% Pseudomonas, 30% Bacillus subtilis, 20% Aspergillus oryzae, 20% Rhizopus; The microbial living bacteria content of described biomass conversion...

Embodiment 2

[0053] 1. Preparation of functional organic fertilizer

[0054] After the straw is crushed, it is mixed with blue-green algae at a mass ratio of 5:10 to obtain a mixture, and then a biomass conversion compound bacterial agent with a mixture quality of 2‰ and a biomass conversion induction material with a mixture quality of 2.5‰ are added to the mixture, and mixed After uniformity, stack and ferment at room temperature for 8 days to obtain a semi-solid organic fertilizer. The semi-solid organic fertilizer obtained after fermentation is compounded and granulated with attapulgite, biomass carbon ash and heavy metal ion chelating agent in a mass ratio of 1000:100:150:5 to obtain a functional organic fertilizer for soil restoration.

[0055] Described biomass conversion compound microbial agent constitutes by mass percentage: 30% Pseudomonas, 30% Bacillus subtilis, 20% Aspergillus oryzae, 20% Rhizopus; The microbial living bacteria content of described biomass conversion composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com