Biomass carbon fiber/layered double metal hydroxide adsorption material for phosphorus removal

A layered bimetallic, hydroxide technology, applied in the directions of alkali metal oxide/hydroxide, alkali metal compound, adsorbed water/sewage treatment, etc., can solve the problem of general adsorption performance of adsorbent, low specific surface area of adsorbent, The surface functional groups are not abundant, and the preparation process is simple and controllable, the preparation cost is low, and there is no secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

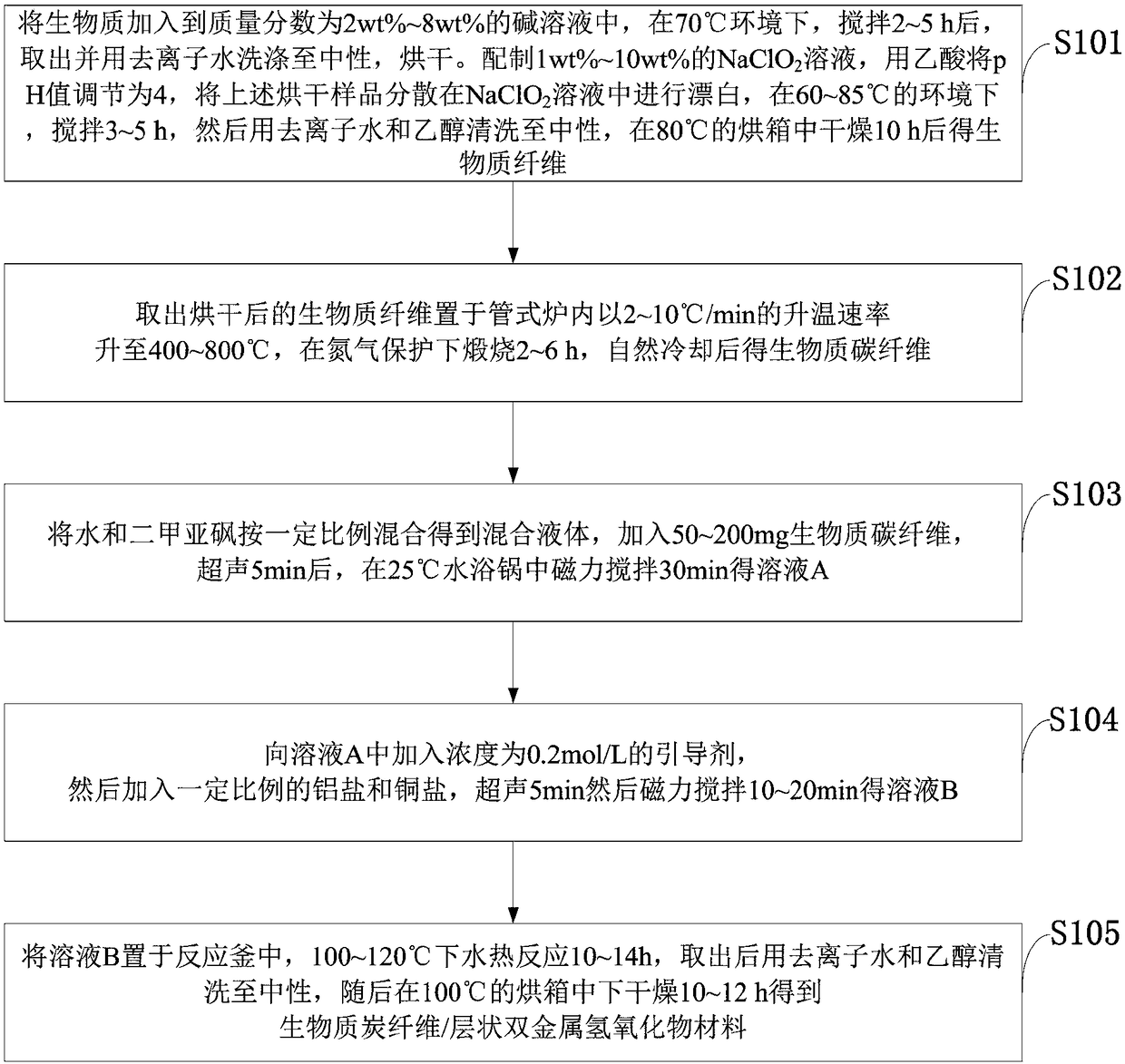

[0024] The invention provides a biomass carbon fiber / layered double metal hydroxide adsorption and dephosphorization material and a preparation method thereof. The preparation process of the material is simple and controllable, and the adsorption performance is improved through the double adsorption effect of the biomass carbon fiber / LDH. To achieve the purpose of efficient and rapid removal.

[0025] The biomass carbon fiber / layered double metal hydroxide adsorption and phosphorus removal material provided in the embodiment of the present invention is composed of biomass carbon fiber and layered double metal hydroxide. Biomass carbon fiber: aluminum salt: copper salt = 1-2:35:45.

[0026] The biomass carbon fiber / layered double metal hydroxide adsorption and dephosphorization material provided by the embodiment of the present invention is a layered double metal hydroxide that grows on the surface of the biomass carbon fiber in a crescent shape, and the biomass carbon fiber is...

Embodiment 1

[0036] The biomass carbon fiber / layered double metal hydroxide adsorption and phosphorus removal material provided by the embodiment of the present invention comprises the following steps:

[0037] a) The waste paper is added to a sodium hydroxide solution with a mass fraction of 2 wt %, stirred for 2 hours at 70° C., taken out, washed with deionized water until neutral, and dried. Prepare a 1wt% NaClO2 solution, adjust the pH value to 4 with acetic acid, and disperse the above-mentioned dried samples in NaClO 2Bleach was carried out in the solution, stirred at 60° C. for 3 hours, then washed with deionized water and ethanol until neutral, and dried in an oven at 80° C. for 10 hours to obtain biomass fibers.

[0038] b) The dried biomass fibers were taken out and placed in a tube furnace at a heating rate of 2°C / min to 400°C, calcined for 2 hours under nitrogen protection, and cooled naturally to obtain biomass carbon fibers.

[0039] c) Mix 30 mL of water and 15 mL of dimeth...

Embodiment 2

[0043] The biomass carbon fiber / layered double metal hydroxide adsorption and phosphorus removal material provided by the embodiment of the present invention comprises the following steps:

[0044] a) The waste paper was added to a potassium hydroxide solution with a mass fraction of 3 wt %, stirred for 3 hours at 70° C., taken out, washed with deionized water until neutral, and dried. Prepare 3wt% NaClO 2 solution, adjust the pH value to 4 with acetic acid, and disperse the above dried sample in NaClO 2 Bleaching was carried out in the solution, and stirred for 3 hours at 65° C.; then washed with deionized water and ethanol until neutral, and dried in an oven at 80° C. for 10 hours to obtain biomass fibers.

[0045] b) The dried biomass fibers were taken out and placed in a tube furnace at a heating rate of 4°C / min to 500°C, calcined for 2 hours under nitrogen protection, and cooled naturally to obtain biomass carbon fibers.

[0046] c) Mix 60 mL of water and 30 mL of dimet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com