Multi-amino carbon composite material for selectively fixing mercury, chromium and lead in polluted soil and preparation method

A technology of polluted soil and composite materials, which is applied in the field of soil environmental safety and resource reuse, can solve the problems of low selectivity and small adsorption capacity of heavy metals in soil, and achieve the effect of large adsorption capacity, low cost and strong selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

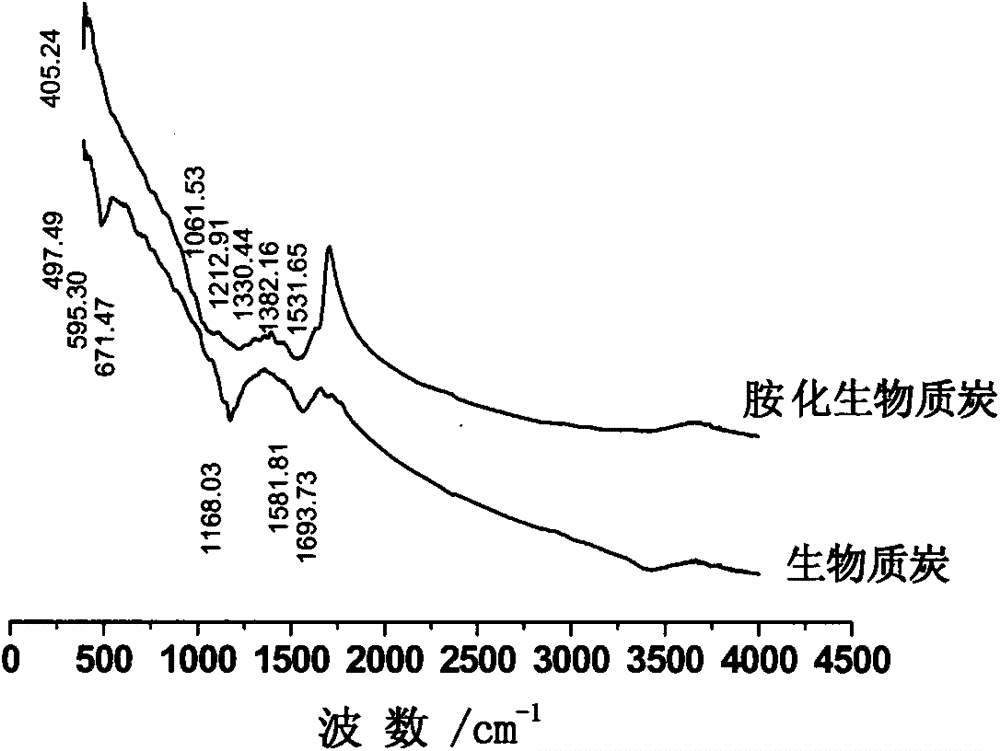

[0022] Soak the washed and dried bagasse powder and phosphoric acid at a mass ratio of 1:1 for 12 hours, place the soaked bagasse powder in an oven at 60°C, pre-carbonize for 10 hours, put it in a microwave reactor, and heat it at 50ml / min Under the protection of the nitrogen flow, the bagasse biochar was obtained by constant temperature activation under the condition of 900W for 22 minutes. The above 5g of biochar was stirred and purified at 60°C for 5 hours with a mass fraction of 10% HCl solution, then the purified biochar powder was added with 300ml of 32.5% nitric acid and stirred for 5 hours, and the above-mentioned nitric acid was weighed. 5g of charcoal powder, add 100ml of ethylenediamine, stir and heat evenly, then add 5g of N,N'-dicyclohexylcarbodiimide, and reflux for 48 hours. The product was washed and dried to obtain a novel polyamine-based biochar composite material. Infrared spectra of biochar materials before and after amination modification figure 1 shown....

example 2

[0024] Soak the washed and dried cotton stalk powder and 80% potassium hydroxide for 12 hours at a mass ratio of 1:2, put the soaked cotton stalk powder in a vacuum dryer for drying, and then put it into the tube type In the furnace, under the protection of a nitrogen flow of 50ml / min, the temperature was raised to 400°C at 5°C / min, and carbonized at this temperature for 2 hours, and then the temperature was raised to 700°C at 10°C / min to activate the cotton stalk biomass carbon. The above-mentioned 5g biochar powder was stirred with 10% HCl solution at 60°C for 5 hours, and then 300ml of 32.5% nitric acid was added to the purified biochar powder and stirred for 5 hours, then it was washed to neutral drying for subsequent use. Weigh 5 g of the above powder, add 100 ml of ethylenediamine, stir and heat, then add N,N'-dicyclohexylcarbodiimide, and react under reflux for 48 hours. The product was washed and dried to obtain a novel polyamine-based biochar composite material.

example 3

[0026] Soak the washed and dried water wheat stalk powder and 30% phosphoric acid at a mass ratio of 2:1 for 12 hours, dry the soaked water wheat stalk powder and put it in a tube furnace, and heat it at 50ml / Under the protection of a nitrogen flow of min, the temperature was raised to 500°C at 5°C / min, and carbonized at this temperature for 1.5 hours. After cooling, it was washed with distilled water until the pH was 7.0. Finally, put the cleaned product into an oven to dry at 105°C. 10g of the above-mentioned biochar powder was stirred with 200ml 10% HCl solution at 60°C for 5 hours, then the purified biochar powder was stirred with 200ml of 32.5% nitric acid for 3 hours, then it was washed to neutral drying. Add 200ml of ethylenediamine to the above sample. After stirring and heating, N,N'-dicyclohexylcarbodiimide was added and refluxed for 36 hours. The product was washed and dried to obtain a novel polyamine-based biochar composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com