Modified biomass carbon for reducing effective state chromium in soil and preparation method and application of modified biomass carbon

A technology of biomass charcoal and biomass, which is applied in the fields of application, soil conditioning materials, chemical instruments and methods, etc., can solve the problems of non-specific adsorption of heavy metals, molecular sieve modification fixation performance, and small particles of powdered activated carbon. Inexpensive, effective, enhance the effect of organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of modified biochar for reducing available chromium in soil, the steps are as follows:

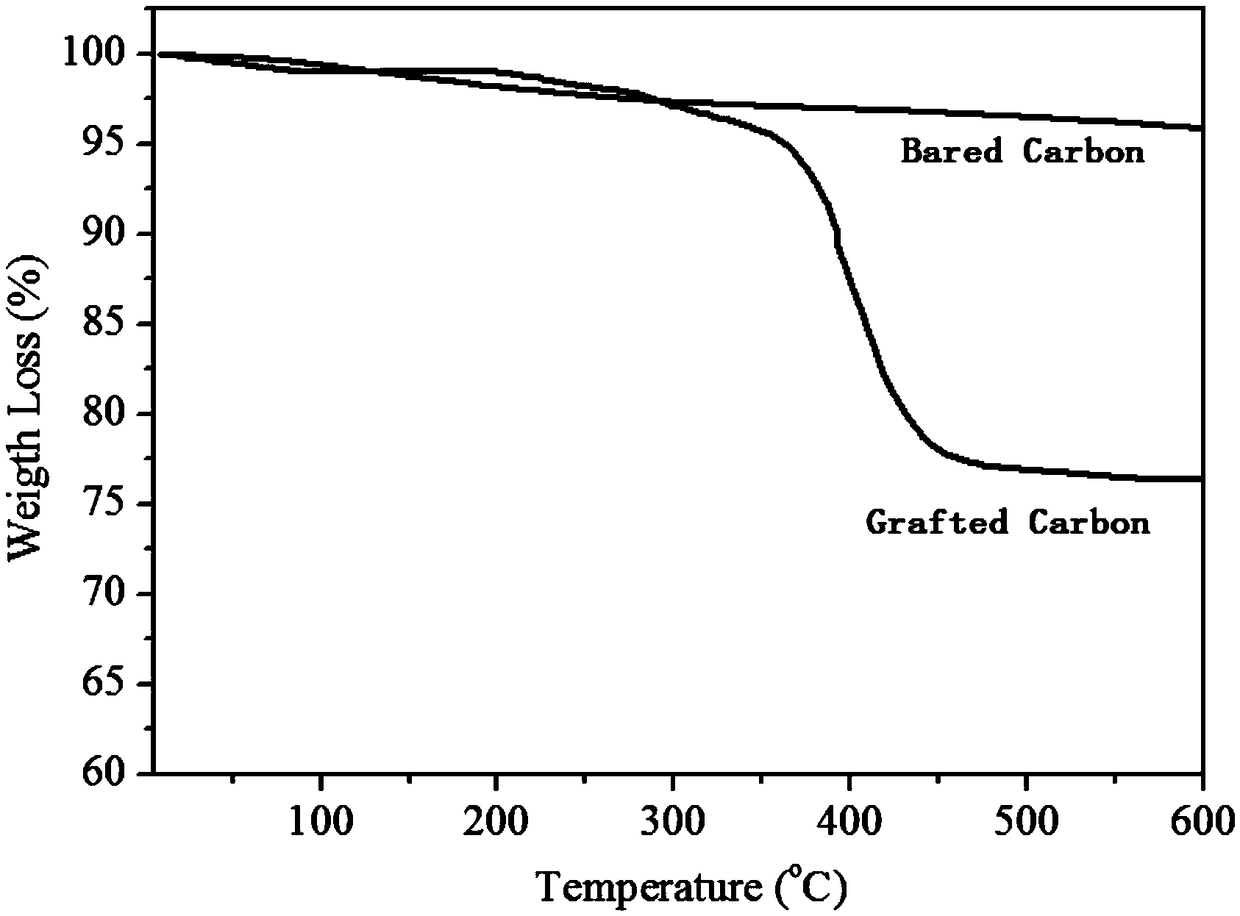

[0029] Add a certain ratio of trimethylammonium salt, N,N'-methylenebisacrylamide and biomass activated carbon into the conical flask, and after standing in the dark for 10-24 hours, add an appropriate amount of initiator to it, and ultrasonically After dissolving, transfer it to a boric acid glass test tube, pass an inert gas to remove oxygen under ice bath conditions; then seal the test tube with a rubber stopper, put it in a water bath at 50-80°C and continue to react for 8-16 hours. After the reaction is over, wash the polymer and remove it. After drying, the final product modified biochar material can be obtained.

[0030] The trimethylammonium salt is a substance having both an ethylenic bond and a trimethylammonium group, which can be methacryloyloxyethyltrimethylammonium chloride and allyltrimethylammonium chloride, but not limited to this.

[0031] Th...

Embodiment 1

[0036] A modified biochar material for reducing available chromium in soil, the specific preparation method of which is as follows:

[0037] (i) Add 40mmol methacryloyloxyethyltrimethylammonium chloride solution, 40mmol N,N′-methylenebisacrylamide solution, and 20g coconut shell charcoal into a 50mL Erlenmeyer flask, and place it in a dark environment set for 10 hours;

[0038] (ii) Add 40 mmol potassium persulfate to the Erlenmeyer flask of step (i), ultrasonically dissolve the mixed solution and transfer it to a boric acid glass test tube, pass nitrogen gas to remove oxygen under ice bath conditions, cover with a rubber stopper and seal it well before putting it into Polymerization was initiated in a water bath at 60°C for 8 hours;

[0039] (iii) A polymer obtained by breaking up the adhered polymer after the reaction is completed. The product was put into a Buchner funnel for suction filtration and washing, repeated extraction and elution with water and methanol, and the ...

Embodiment 2

[0041] A modified biochar material for reducing available chromium in soil, the specific preparation method of which is as follows:

[0042] (i) Add 80mmol methacryloyloxyethyltrimethylammonium chloride solution, 40mmol N,N'-methylenebisacrylamide solution, and 50g bamboo charcoal into a 50mL Erlenmeyer flask, and let it stand in the dark for 24 hours later;

[0043] (ii) Add 40 mmol potassium persulfate to the Erlenmeyer flask of step (i), ultrasonically dissolve the mixed solution and transfer it to a boric acid glass test tube, pass argon to deoxygenate under ice bath conditions, cover with a rubber stopper and seal it well Throw it into a 70°C water bath to initiate polymerization and last for 12 hours;

[0044] (iii) After the reaction is completed, crush the adhered polymer to obtain the polymer, put the product into a Buchner funnel for suction filtration and washing, repeatedly extract and elute with water and methanol, and obtain the final product after drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com