Crop seed coating agent prepared from novel biomass carbon of agricultural wastes and preparation method of coating agent

A technology of agricultural waste and biochar, which is applied in the field of crop seed coating agent and its preparation, to achieve obvious economic and environmental benefits, and the effect of human and animal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The new biochar coating agent comprises the following components in percentage by weight of seeds: 10% of biochar, 50% of filler, 1% of binder and 0.3% of dispersant.

[0022] Pour the seeds into the container, spray sodium alginate aqueous solution (concentration 1%, v / v) and ethylene glycol aqueous solution (concentration 0.3%, v / v) to moisten the surface of the seeds, add 1 / 4-1 / 5 soap Soil to make it evenly adhere to the surface of the seeds, repeat this 3-4 times, the thickness of the coating layer is 0.5mm; add the mixture of biochar and the remaining filler, shake the container until the coating material evenly adheres to the surface of the seeds, and place it for ventilation Dry in the shade for 1-2 hours in a dry place.

Embodiment 2

[0023] Germination rate, germination potential comparison of seed after embodiment 2 coating

[0024] The experimental group adopts the coated seeds prepared in Example 1, and two groups of control groups are set up, which are respectively CK group: adopt plump and non-residual corn seeds; and traditional group: adopt seeds coated with fertilizer type coating agent (in the seed Add necessary micronutrients and NPK macronutrients during the pelleting process), put 500g of air-dried and crushed soil through a 20-mesh sieve into each group of containers, plant 7 seeds, and supplement every 2 days Moisture should be kept at about 70% of the field water capacity. The operation was carried out according to the national seed inspection regulations, and the germination potential was measured after 4 days, and the germination rate was measured after 10 days.

[0025] Table 1

[0026]

[0027] Germination rate (%) = final germination number / tota...

Embodiment 3

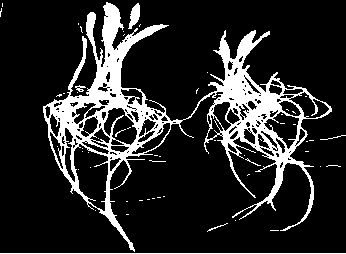

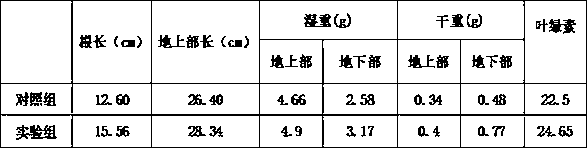

[0028] Example 3 Effects on the Growth of Maize Seedlings

[0029] The experimental set-up, samples, and planting conditions were the same as those in Example 2. The days of indoor cultivation were 10 days, and the inspection indicators were corn root length, above-ground length, wet weight, dry weight, and chlorophyll. The results are shown in Table 2, figure 2 :

[0030] Table 2

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com