Preparation method of low melting point aluminum-boron-silicon glass ceramic bond for CBN (Cubic Boron Nitride) grinding tool

A technology of vitrified bond and low-melting glass, which is applied in the field of preparation of CBN abrasive grain (preparation of CBN abrasive tool) bond, which can solve problems such as abrasive grain shedding, large cracks, and reduced service life of grinding wheel, and achieve convenient crystallization control , low thermal expansion coefficient, and low softening temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

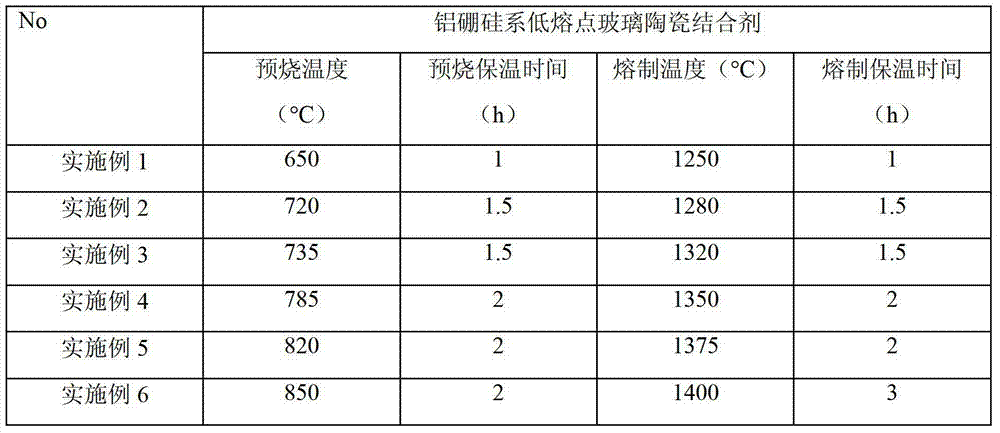

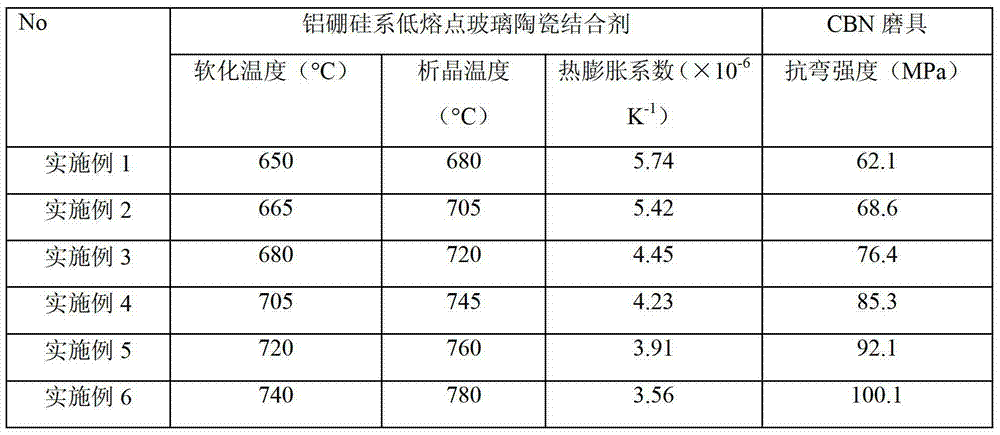

Examples

Embodiment Construction

[0023] The present invention adopts conventional chemical raw materials and conventional molten water quenching method to prepare, under the premise of ensuring that the melted glass has a lower softening temperature, by adjusting the B in the glass composition 2 o 3 and Na 2 O, K 2 O, Li 2 The mass percentage content of oxides such as O and B 2 o 3 The molar ratio of the alkali metal oxide makes the lithium-aluminosilicate glass not only have a low softening temperature, but also have low thermal expansion coefficient and high mechanical strength and other superior properties; at the same time, when used as a glass-ceramic bond for CBN abrasive tools, through the Sintering and heat preservation above the softening temperature can precipitate fine spodumene crystallites, further reduce the thermal expansion coefficient of the glass and improve the mechanical strength of the glass at the same time, so as to achieve the purpose of improving the processing performance of CBN ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com