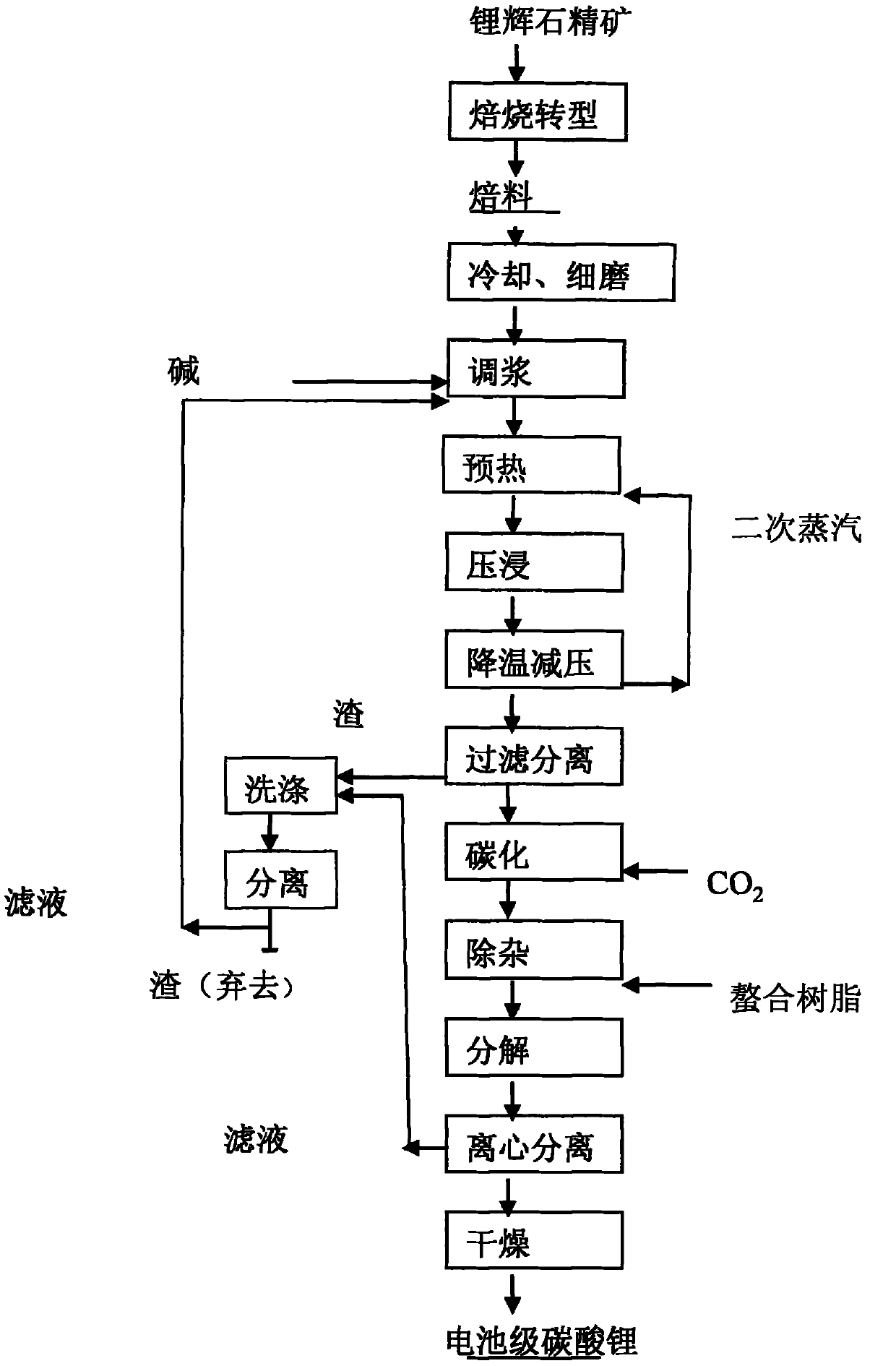

Method for extracting lithium salt from spodumene

A spodumene, lithium extraction technology, applied in lithium carbonate;/acid carbonate, improvement of process efficiency, etc., can solve the problems of high energy consumption, high production cost, long industrial process, etc. of the lime method, To achieve the effect of stable product quality, low production cost and high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

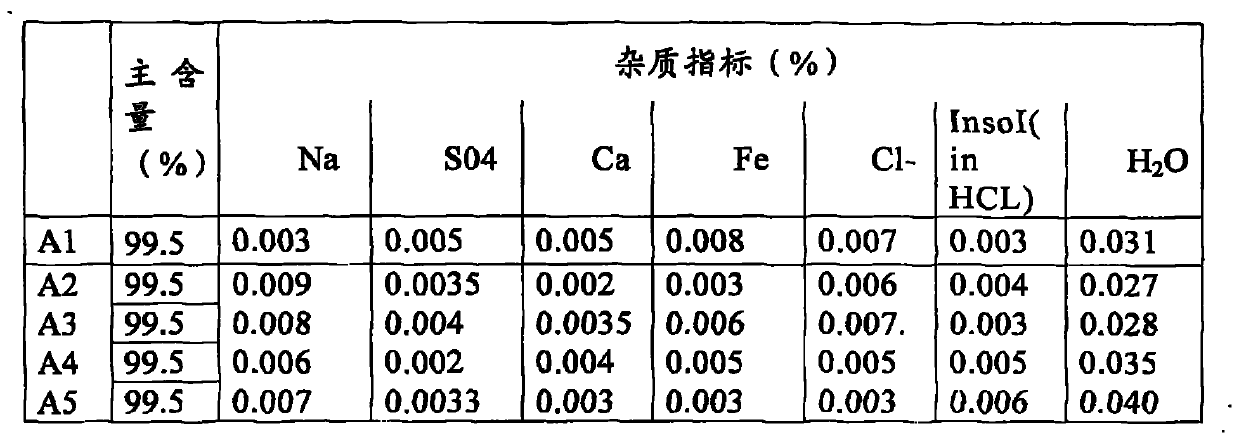

Embodiment 1

[0040] 〔1〕The spodumene concentrate is placed in an internally heated rotary furnace, hot dirty gas and air are introduced at 350°C, and converted and roasted at a high temperature of 1250°C to convert from α-type to β-type;

[0041] [2] Cooling and grinding: the roasted material still has high residual heat, so it is cooled to normal temperature by heat exchange; in the process of pressure cooking, in order to make the roasted material and the material liquid have enough contact surface, the roasted and ground To 325 mesh, the content of lithium oxide was analyzed to be 5.13%.

[0042] 〔3〕Slurry mixing: add soda ash and finely ground spodumene to a corresponding amount of water to prepare a slurry, control the molar ratio of sodium to lithium to 4, and the liquid-solid ratio to 4, and the weight of soda ash is included in the liquid phase.

[0043] 〔4〕Press immersion: use high-pressure steam to raise the temperature of the slurry to 210°C, the corresponding pressure of the hi...

Embodiment 2

[0051] 〔1〕The spodumene concentrate is placed in an internally heated rotary furnace, hot dirty gas and air are introduced at 350°C, and converted and roasted at a high temperature of 1150°C to convert from α-type to β-type;

[0052] [2] Cooling and grinding: In order to make the roasted material and the material liquid have sufficient contact surface during the pressure cooking process, the roasted material is ground to 200 meshes, and the content of lithium oxide is analyzed to be 5.03%.

[0053] 〔3〕Slurry mixing: add caustic soda and finely ground spodumene to a corresponding amount of water to prepare a slurry, control the molar ratio of sodium to lithium to 4.5, and the liquid-solid ratio to 4.5, and the weight of caustic soda is included in the liquid phase.

[0054] 〔4〕Press immersion: Use high-pressure steam to raise the temperature of the slurry to 230°C, the corresponding pressure is 2.2Mpa, and the constant temperature and pressure time is 2h.

[0055] 〔5〕Reducing t...

Embodiment 3

[0063] 〔1〕Put the spodumene concentrate in an internally heated rotary furnace, introduce hot dirty gas and air at 330°C, and convert and roast at a high temperature of 1200°C to convert from α-type to β-type;

[0064] [2] Cooling and grinding: In order to make the roasted material and the material liquid have sufficient contact surface during the pressure cooking process, the roasted material is ground to 325 mesh, and the content of lithium oxide is analyzed to be 5.08%.

[0065] 〔3〕Slurry mixing: ammonium bicarbonate (NH4) 2 CO 3 Add the corresponding amount of water to the finely ground spodumene to prepare a slurry, control the molar ratio of sodium to lithium to 2, the ratio of liquid to solid to 3, and the weight of ammonium bicarbonate is included in the liquid phase.

[0066] 〔4〕Press immersion: Use high-pressure steam to raise the temperature of the slurry to 180°C, the corresponding pressure is 1.1Mpa, and the constant temperature and pressure time is 1.5h.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com