Measuring equipment and measuring method for eccentricity ratios of large-diameter preform

A technology of measuring equipment and measuring methods, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of high laser requirements, increased weight, and poor adaptability to product changes, and achieve simple equipment structure, low input cost, and adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

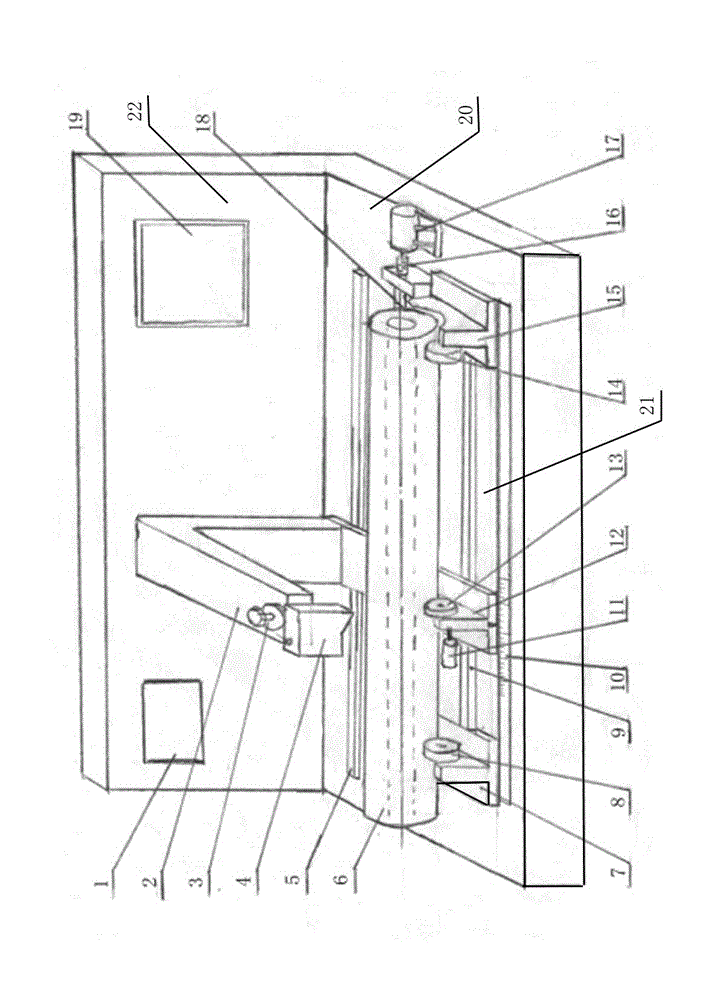

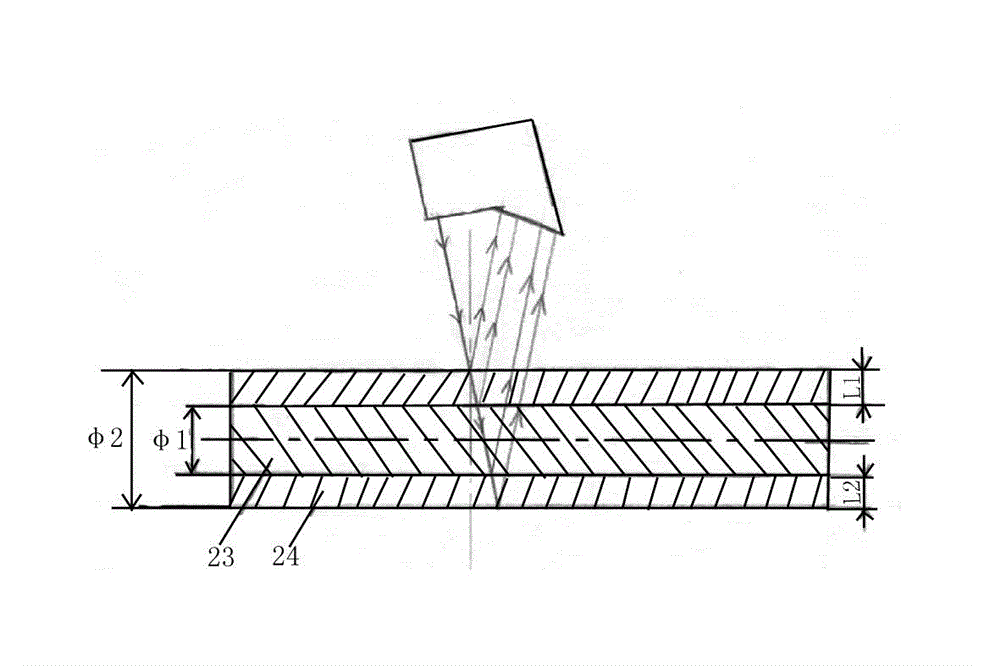

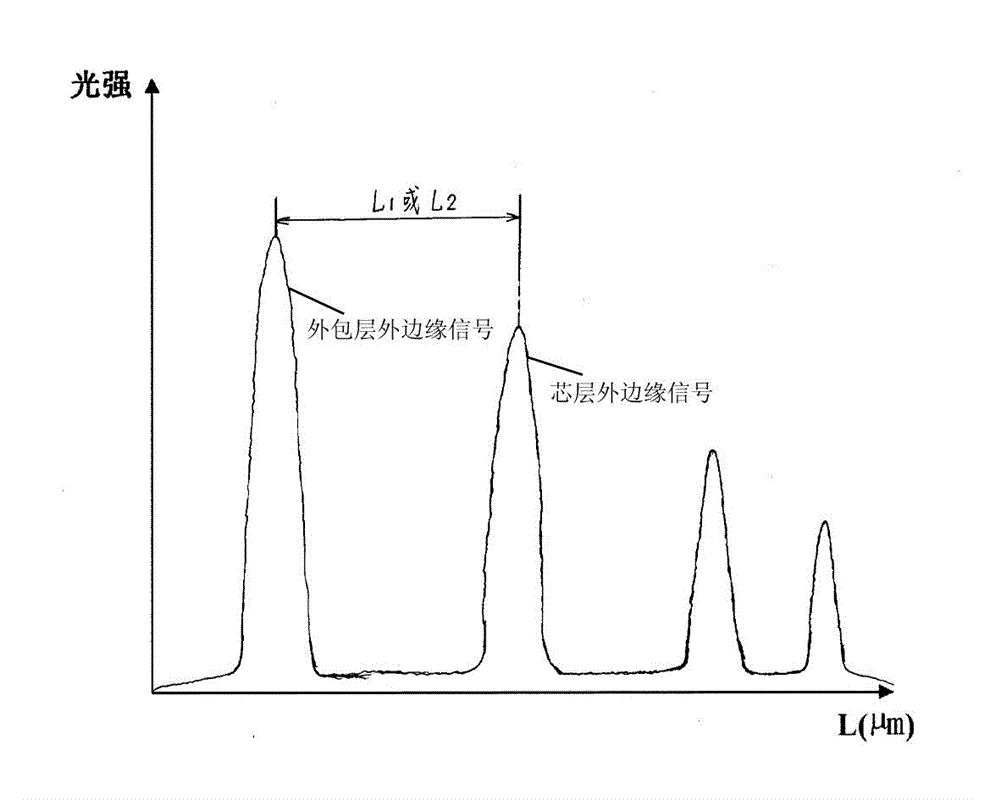

[0025] Refer to attached Figure 1~3A device for measuring the eccentricity of a large-diameter preform includes a measuring table 20, a moving slide table 21, a measuring table back plate 22, a detection data display screen 1, a data output display screen 19, a laser transmitter and receiver bracket 2, and an adjustment knob 3 , Laser transmitter receiver 4, rear linear guide rail 5, left fixed roller bracket 7, left support roller 8, front linear guide rail 9, scale 10, rotating motor 11, moving bracket 12, supporting rod rotating roller 13, right fixed Roller bracket 15, right supporting roller 14, left and right movement motor 17 and left and right movement lead screw; Measuring platform backboard 22 is installed on measuring platform 20 rear end tops, is provided with testing data display screen 1 and on measuring platform backplane 22 Data output display screen 19; mobile slide table 21 is installed on the front linear guide rail 9 of measuring platform 20, left fixed ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com