Caseless rearview mirror assembly

a rearview mirror and assembly technology, applied in the field of rearview mirror assemblies for vehicles, can solve the problems of unattractive size, heavy mirror housing/casing, and impaired vibration performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

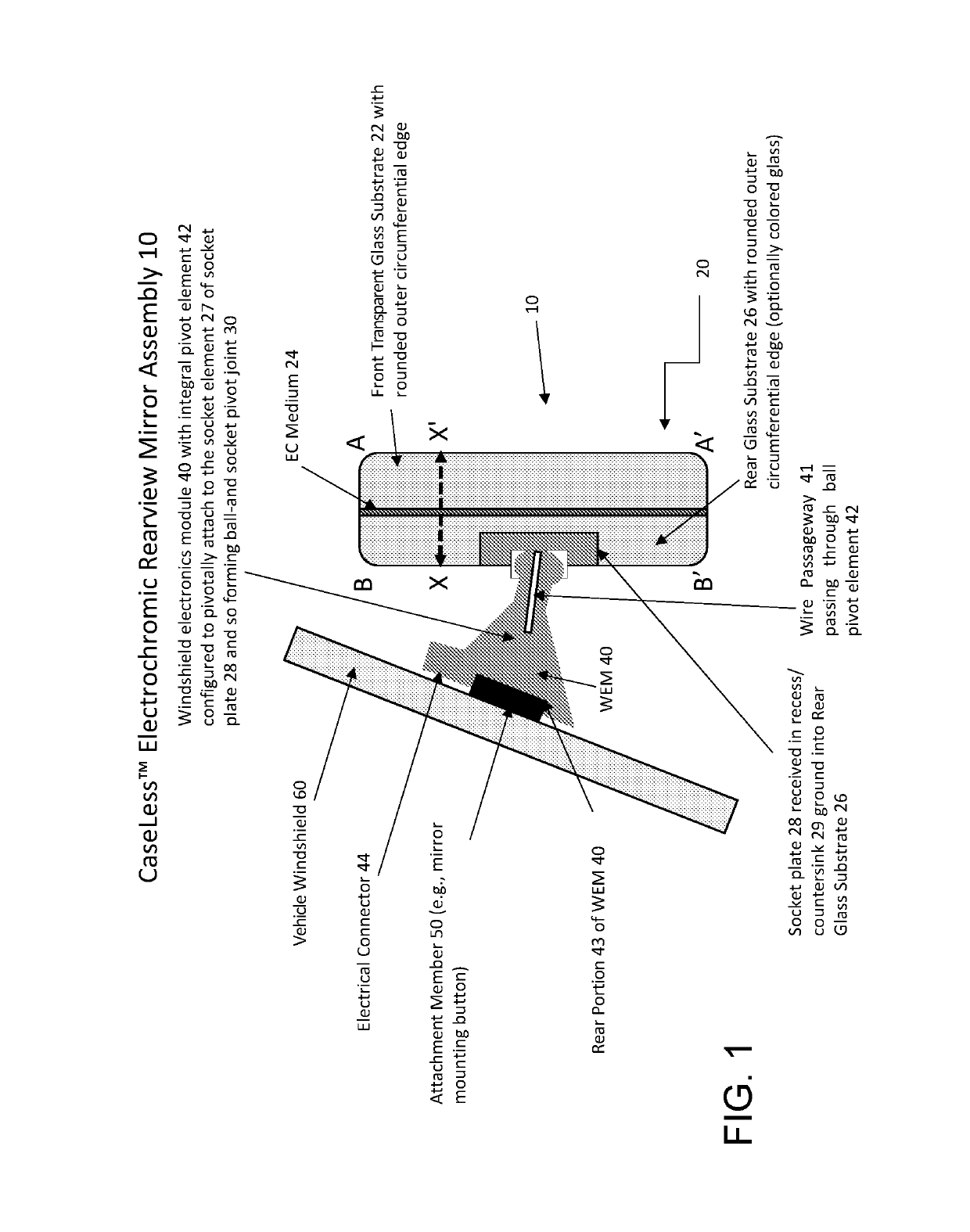

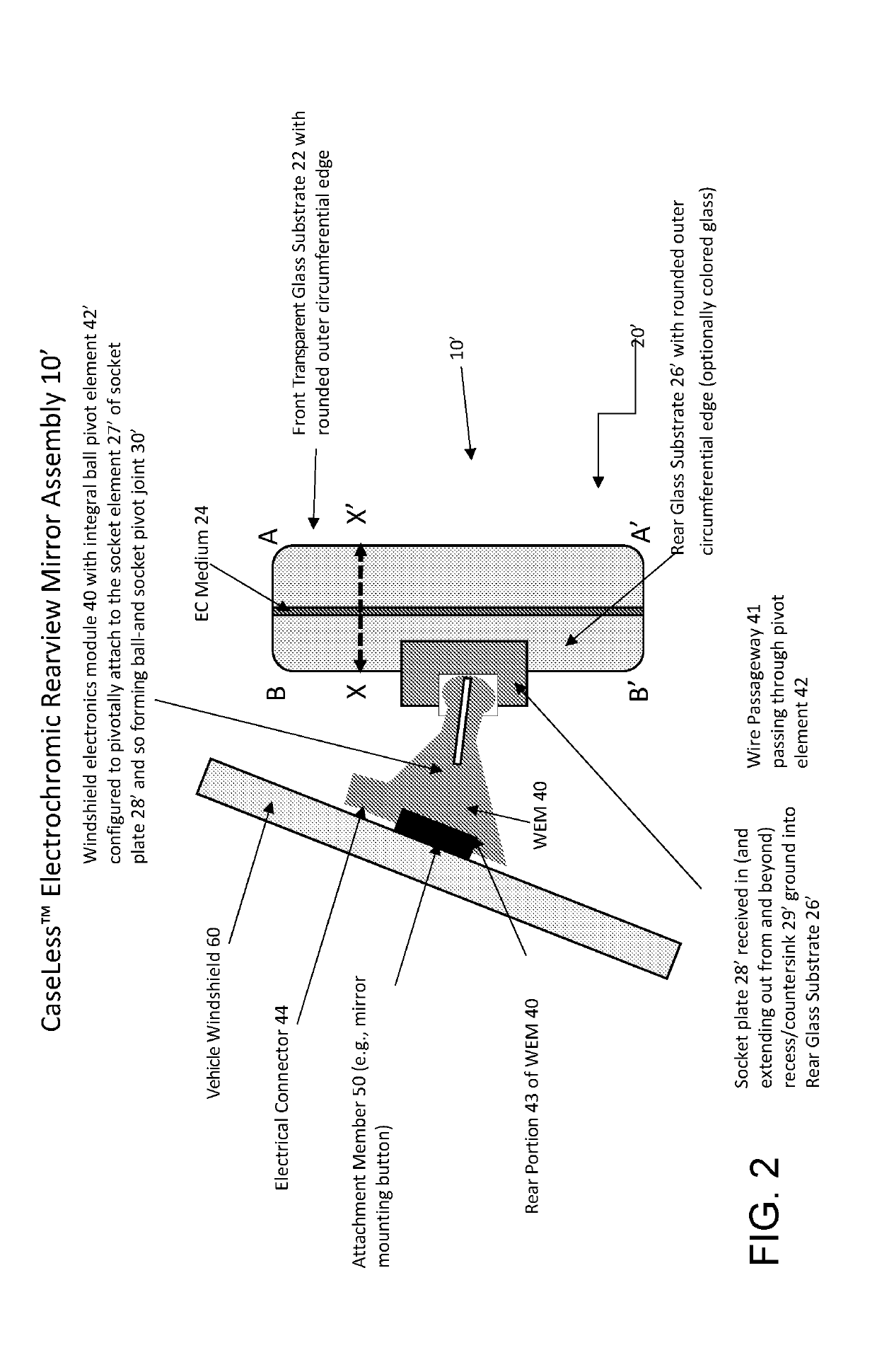

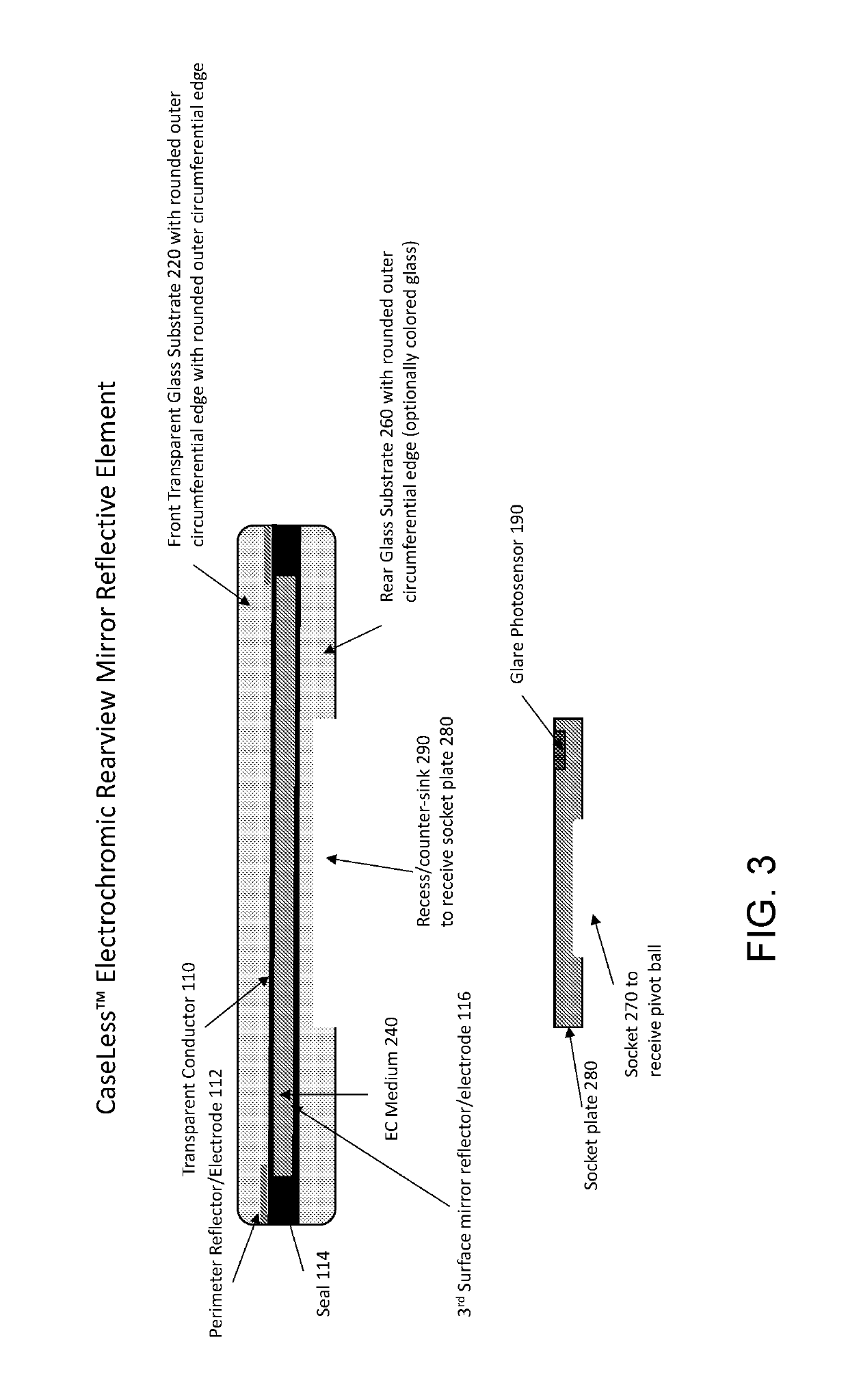

[0043]FIG. 1 shows an embodiment of an interior electrochromic rearview mirror assembly 10 that does not have a mirror case in accordance with the present invention. Caseless interior electrochromic rearview mirror assembly 10 comprises interior electrochromic rearview mirror reflective element 20 that pivots (via ball-and-socket pivot joint 30) about windshield electronics module (WEM) 40 that is adapted for attaching to (and demounting from) attachment member 50 that is bonded by adhesive to the inner surface of windshield 60. Interior electrochromic rearview mirror reflective element 20 comprises a front transparent glass substrate 22 and a rear glass substrate 26 that sandwich an electrically-dimmable electrochromic (EC) medium 24. Examples of suitable EC media to use are disclosed in U.S. Pat. Nos. 6,420,036; 5,724,187 and 5,688,663; 5,128,799; 5,073,012; 5,115,346; 5,140,455; 5,142,407; 5,151,816; 5,239,405; 5,500,760 and 5,424,865, which are hereby incorporated herein by refe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com