A laser beam combining system and a laser beam combining method

A technology of combining laser beams and laser beams, applied in optics, optical components, instruments, etc., can solve the problems of high manufacturing process requirements and technical difficulties, and achieve the effect of meeting the requirements of high laser power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

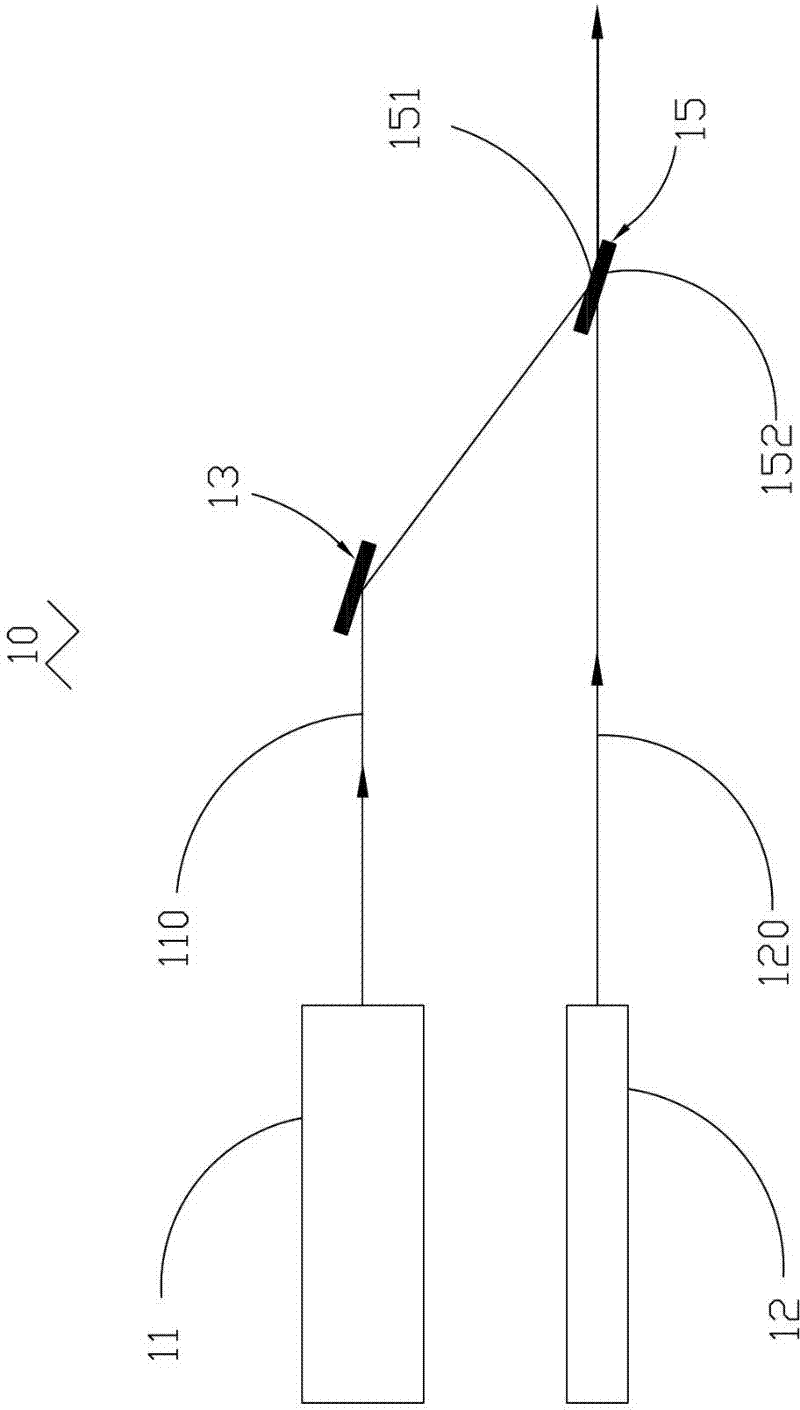

[0016] see figure 1 , The present invention provides a laser beam combining system and a laser beam combining method. The laser beam combining system 10 includes a first laser 11 , a second laser 12 , a mirror 13 and a beam combining mirror 15 .

[0017] In this embodiment, the first laser 11 and the second laser 12 are lasers of the same model, and can emit laser beams with the same parameters. The laser beam 110 emitted by the first laser 11 and the laser beam 120 emitted by the second laser 12 for linearly polarized light. The beam combiner 15 is a thin film polarizer (TFP, thin film polarizer), and the beam combiner 15 includes a first mirror 151 and a second mirror 152 . When the light is incident on the beam combiner 15 at the Brewster angle, the incident surface is a plane determined by the incident light and the normal of the mirror ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com