Mirror reflection type electrochromic device and preparation method thereof

An electrochromic device and specular reflection technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of driving up the cost of the device, increasing the cost, increasing the cost of the device, etc., and achieve the effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

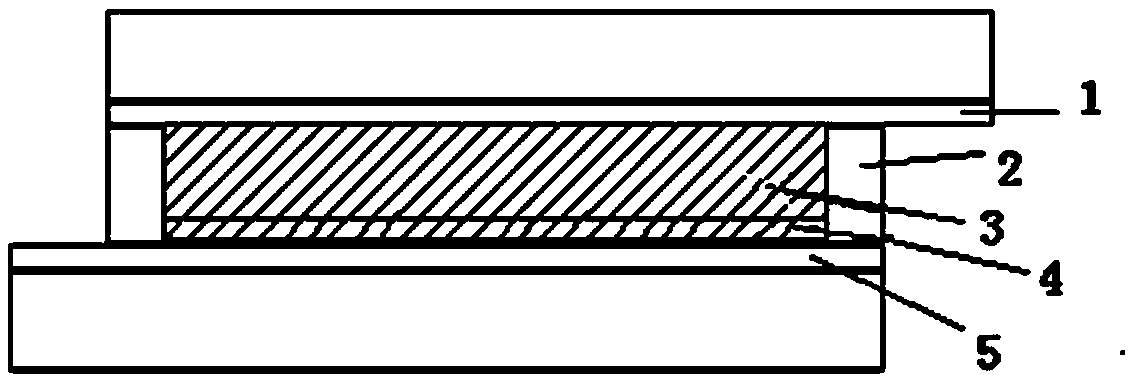

[0036] Such as figure 1 As shown, a specular reflection electrochromic device, including transparent conductive glass 1, insulating spacer 2, gel electrolyte 3, zinc oxide (ZnO) nanocrystal 4 and zinc aluminum oxide (AZO) arranged from top to bottom Transparent conductive glass 5, wherein zinc oxide nanocrystals are deposited on the electrode of zinc oxide aluminum transparent glass 5 to form a rough surface, the surface of transparent conductive glass 1 is a smooth transparent electrode; gel electrolyte 3 is packaged with packaging material; The electrolyte 3 is located between the transparent conductive glass 1 and the zinc-aluminum oxide transparent conductive glass 5 , and the insulating spacer 2 is used to ensure a small distance between the transparent conductive glass 1 and the zinc-aluminum oxide transparent conductive glass 5 . The preparation method uses AZO conductive glass as the substrate and zinc acetate as the zinc source to prepare zinc oxide nanocrystals. The ...

Embodiment 2

[0043] Such as figure 1As shown, a specular reflection electrochromic device, including transparent conductive glass 1, insulating spacer 2, gel electrolyte 3, zinc oxide (ZnO) nanocrystal 4 and zinc aluminum oxide (AZO) arranged from top to bottom Transparent conductive glass 5, wherein zinc oxide nanocrystals are deposited on the electrode of zinc oxide aluminum transparent glass 5 to form a rough surface, the surface of transparent conductive glass 1 is a smooth transparent electrode; gel electrolyte 3 is packaged with packaging material; The electrolyte 3 is located between the transparent conductive glass 1 and the zinc-aluminum oxide transparent conductive glass 5 , and the insulating spacer 2 is used to ensure a small distance between the transparent conductive glass 1 and the zinc-aluminum oxide transparent conductive glass 5 . The preparation method uses AZO / Ag / AZO three-layer structure thin film conductive glass as the substrate, zinc nitrate as zinc source to prepar...

Embodiment 3

[0049] Such as figure 1 As shown, a specular reflection electrochromic device, including transparent conductive glass 1, insulating spacer 2, gel electrolyte 3, zinc oxide (ZnO) nanocrystal 4 and zinc aluminum oxide (AZO) arranged from top to bottom Transparent conductive glass 5, wherein zinc oxide nanocrystals are deposited on the electrode of zinc oxide aluminum transparent glass 5 to form a rough surface, the surface of transparent conductive glass 1 is a smooth transparent electrode; gel electrolyte 3 is packaged with packaging material; The electrolyte 3 is located between the transparent conductive glass 1 and the zinc-aluminum oxide transparent conductive glass 5 , and the insulating spacer 2 is used to ensure a small distance between the transparent conductive glass 1 and the zinc-aluminum oxide transparent conductive glass 5 . The preparation method adopts FTO / AZO composite film, and potassium iodide is iodine-containing or bromine-containing compound salt. Specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com