Attitude-controllable laser milling composite polishing synchronous machining method

A laser milling and compound polishing technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high brittleness, burrs, and difficult processing of functional structural features.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

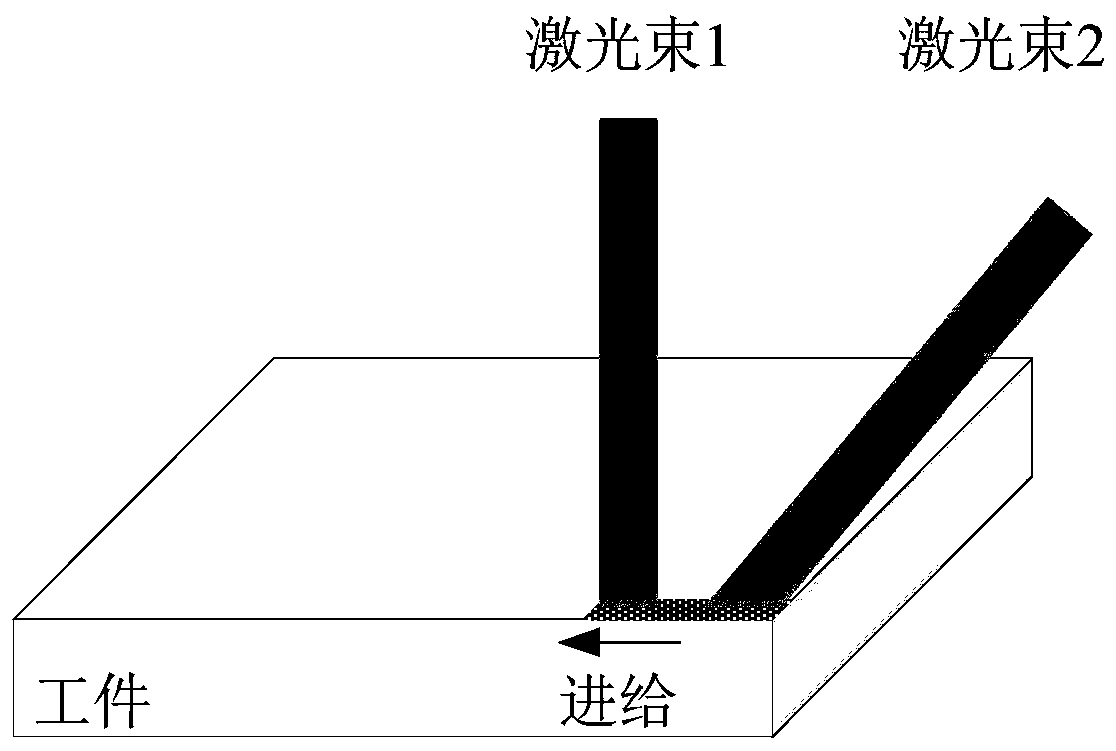

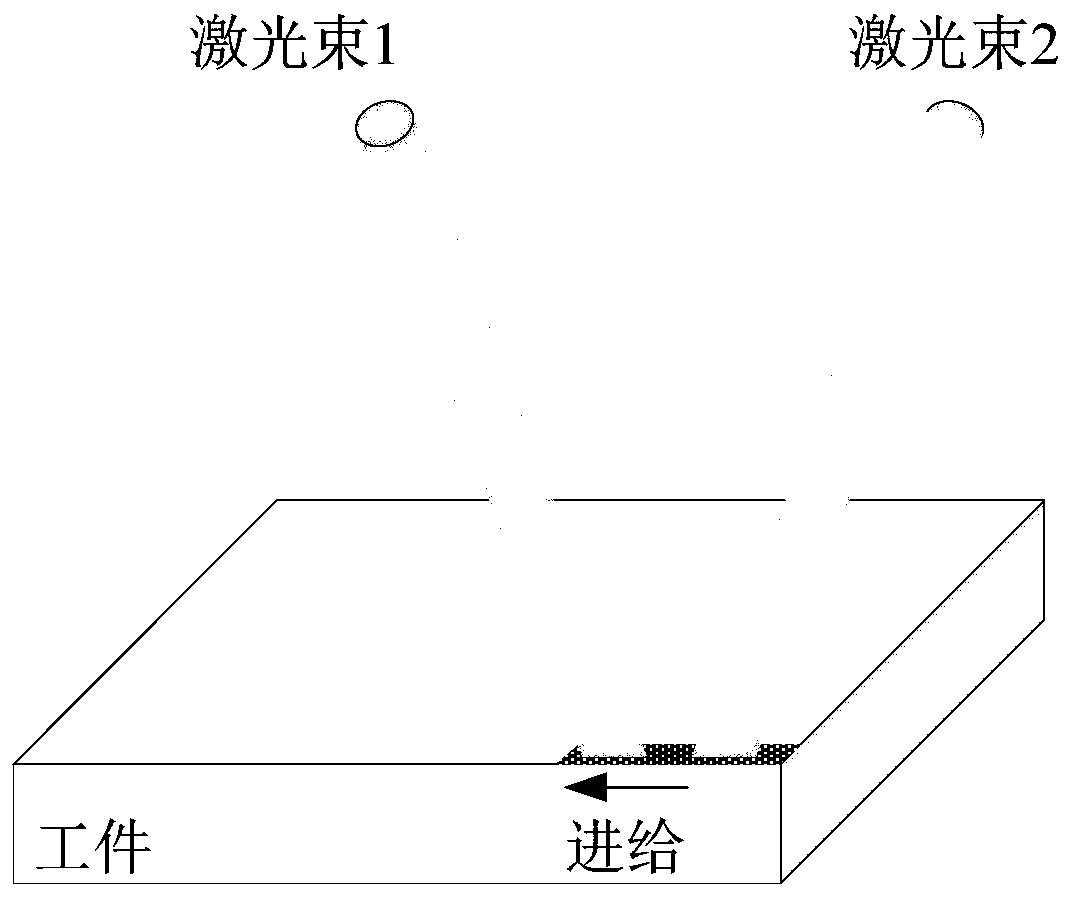

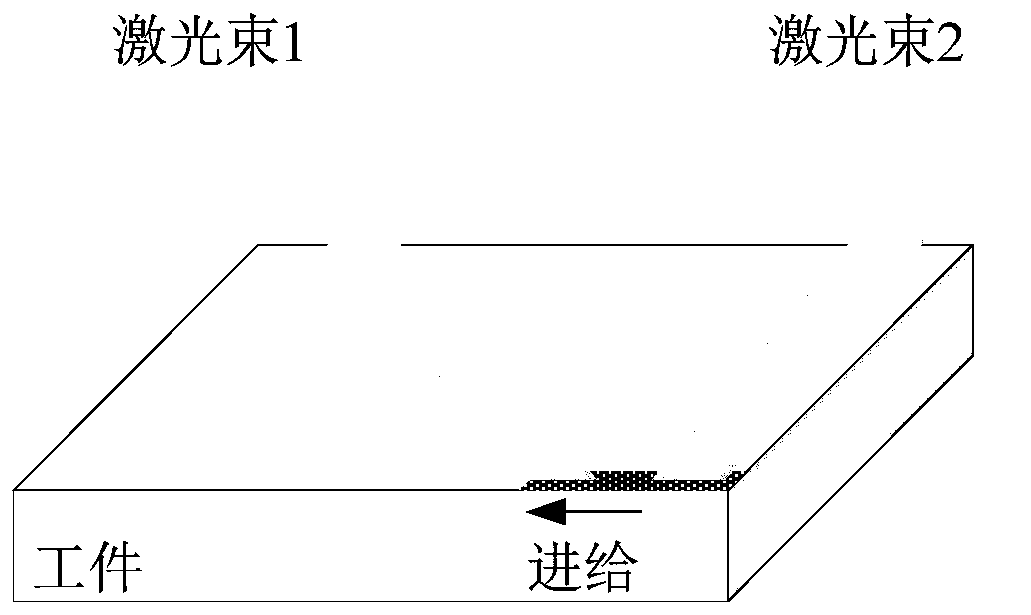

[0043] Figure 6-1 For the workpiece to be processed, a groove with high surface quality is processed on the workpiece by using the attitude controllable laser milling compound polishing synchronous processing method, such as Figure 6-3 shown, specifically by Figure 6-2 processed as shown. Among them, laser beam 1 can use high-power laser, with the core goal of achieving high material removal rate processing, weakening the thermal influence and considering the quality of surface processing, and quickly process the preliminary shape of the groove, while laser beam 2 can use ultra-short pulse laser, Such as picosecond, femtosecond laser, etc., for fine processing.

Embodiment 2

[0045] see Figure 7 , Figure 7 It is a schematic diagram of the principle of processing local curved surfaces and planar through grooves on the workpiece by the attitude-controllable laser milling compound polishing synchronous processing method; where the laser beam 1 can use a high-power laser, with the core goal of achieving a large material removal rate processing, weakening In consideration of thermal influence and surface processing quality, the preliminary shape of the contour (curved surface, plane) can be quickly processed, and the relative posture of the beam and the workpiece can be adjusted for the processing of the curved surface area to achieve a better removal effect; and the laser beam 2 can use ultrashort pulses Lasers, such as picosecond and femtosecond lasers, etc., combine the relative attitude control between the beam and the normal direction of the processing point to perform high-quality fine polishing processing. For example, a five-axis linkage CNC l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com