Micro-channel heat exchanger with multiple flow path interconnection structures and method for manufacturing micro-channel heat exchanger

A technology of micro-channel heat exchanger and interconnection structure, applied in the direction of indirect heat exchanger, heat exchanger type, heat exchanger shell, etc. Thermal coefficient decline and other problems, to achieve the effect of solving the problem of boiling instability, low production cost, and inhibit backflow phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

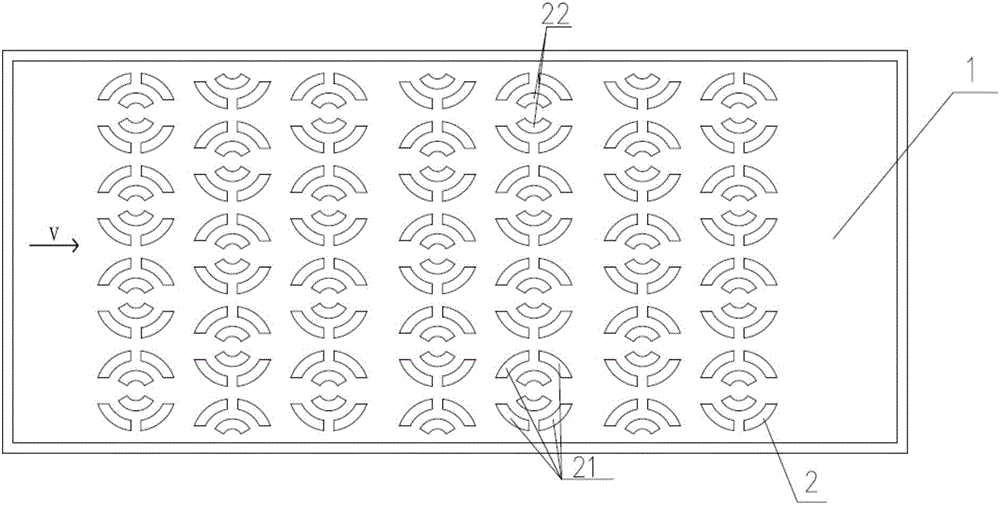

[0032] A microchannel heat exchanger with a multi-flow path interconnection structure includes a metal microchannel substrate 1, such as figure 1 As shown, it is characterized in that: it comprises some open ring structures 2 arranged in parallel and arranged in an array along the flow direction of the coolant;

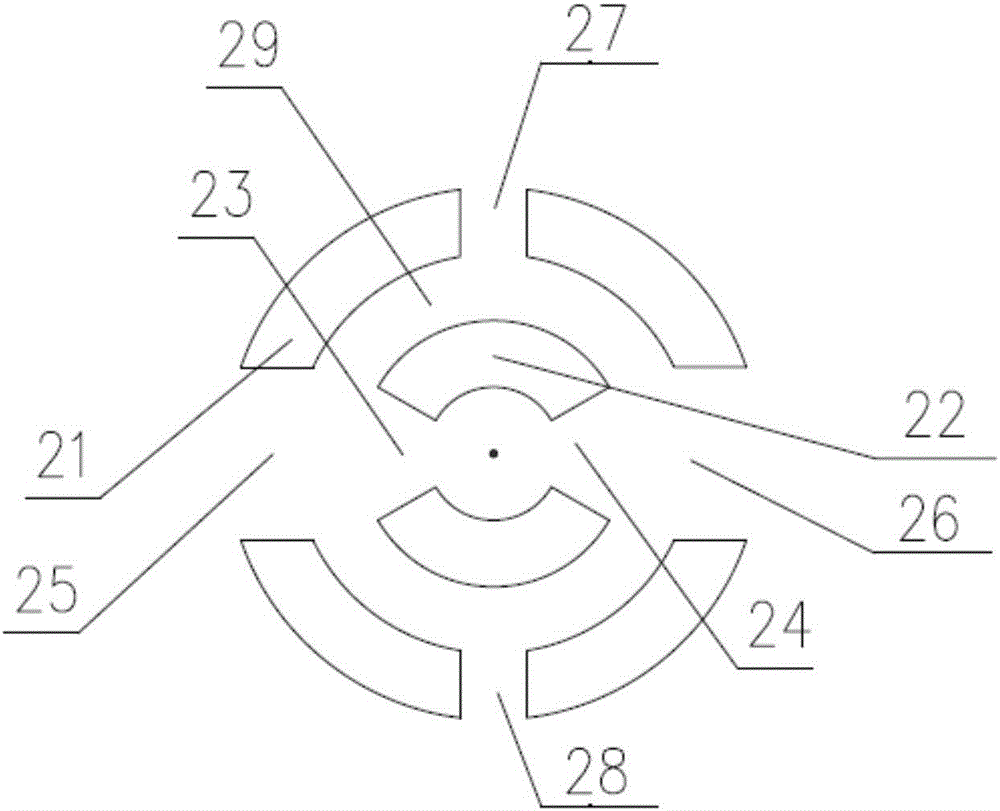

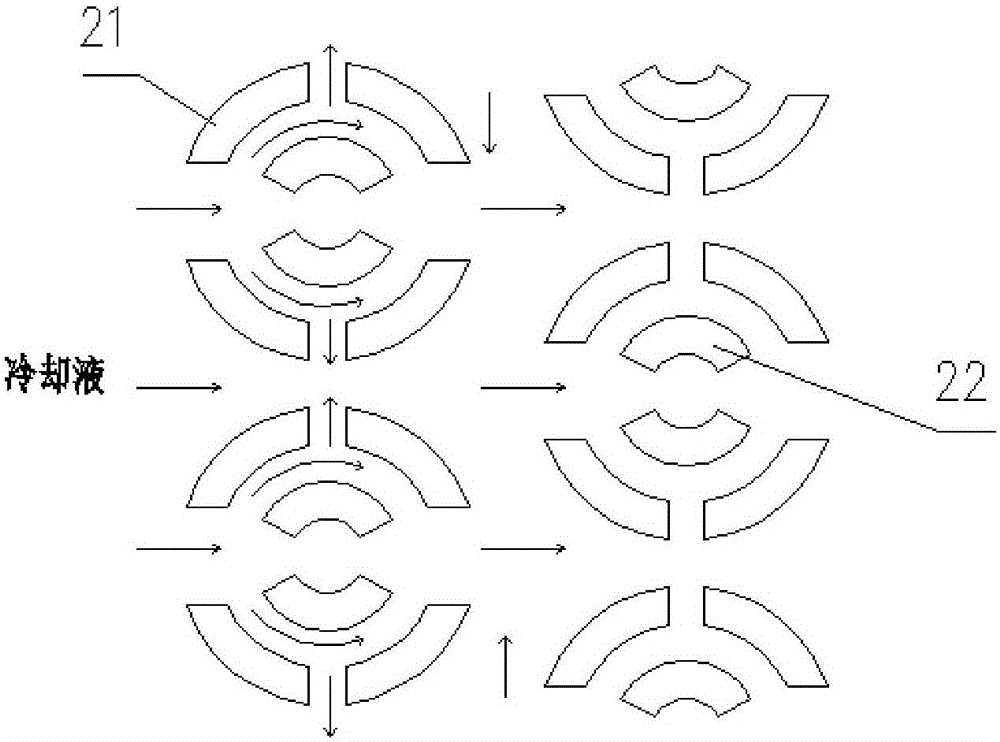

[0033] The open ring structure is as figure 2 As shown, they are symmetrically distributed parallel to and perpendicular to the flow direction of the cooling liquid; each open ring structure 2 includes four sections of first arc-shaped fins 21 uniformly arranged at intervals along the circumferential direction, and arranged on the four sections of the first arc-shaped fins 21 Two sections of second arc-shaped fins 22 arranged symmetrically along the circumferential interval inside an arc-shaped fin 21; thus forming a nested large opening ring and a small opening ring;

[0034] The outer four-segment arc-shaped fins 21 respectively form front and rear two slits 25, 2...

Embodiment 2

[0046] A microchannel heat exchanger with a multi-flow path interconnection structure includes a metal microchannel substrate 3, such as Figure 7 shown. The only difference from Embodiment 1 is that each of the open ring structures 2 is divided into an upper half and a lower half symmetrically arranged along the coolant flow direction, and the upper half of the upper row of open ring structures 2 is connected to the The upper half of the next row of open ring structures 2 is arranged flush, thereby forming Figure 7 The non-interleaved multi-stream interconnected microchannels shown. All the other features are the same as in Implementation 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com