Laser milling method for hard brittle material

A hard and brittle material, laser milling technology, used in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of high melting point hard and brittle materials without relevant reports, and achieve easy promotion, simple method and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Solid-state pulsed laser machining of cemented carbide molds.

[0024] Cemented carbide is widely used as a tool and mold material in industry. It is sintered at high temperature with hard phase WC with a particle size of 0.8-3 μm and Co with a particle size of 0.7-1.1 μm as the binder phase. The hardness is extremely high, and the hardness at room temperature reaches HRA89-93, which is difficult to process by conventional machining methods.

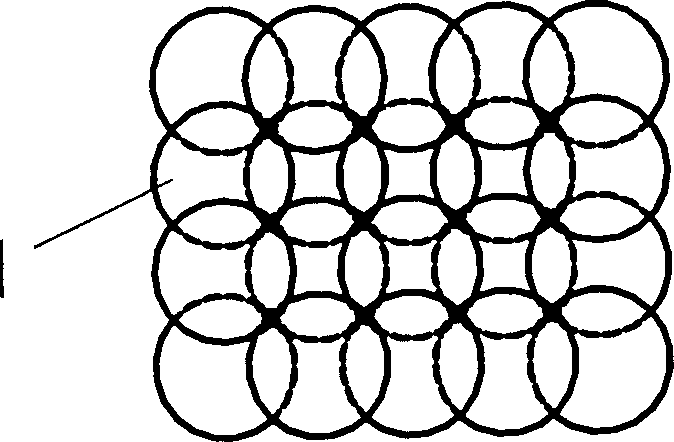

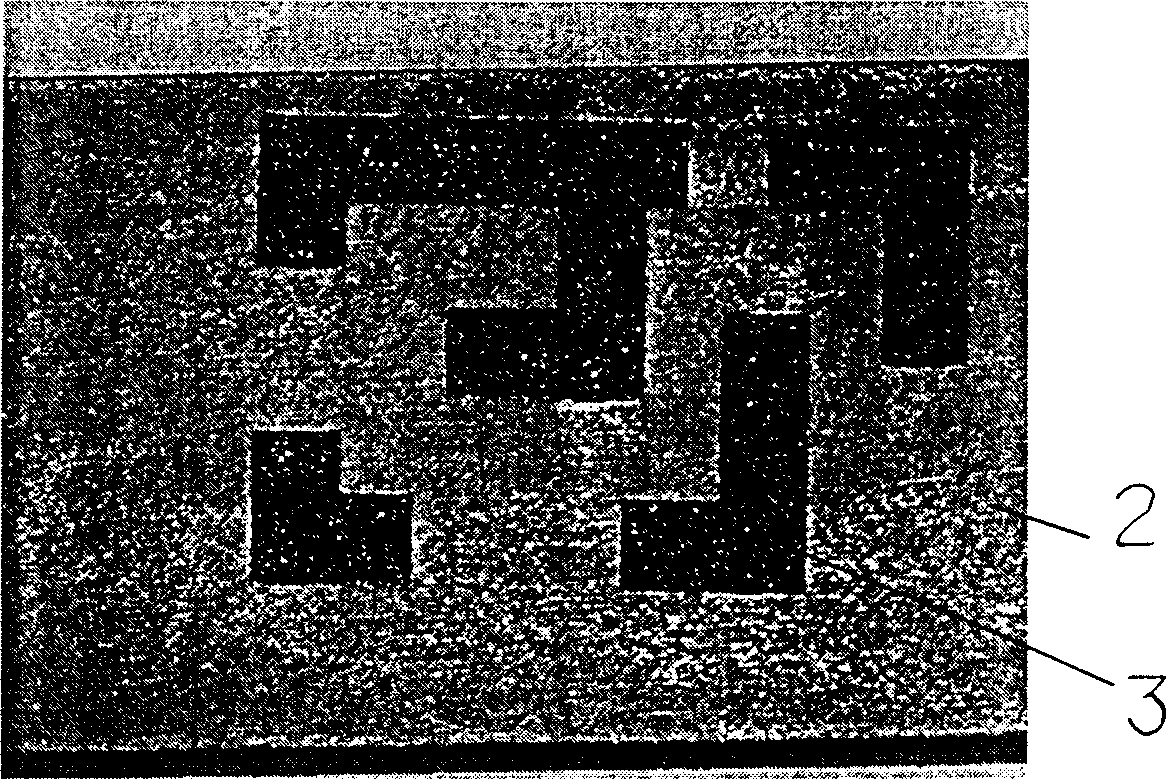

[0025] In this embodiment, first draw on the computer figure 2 The milling contour figure 3 shown, and then draw the section line, note that the section line spacing is set to 0.2mm, the section line is a set of horizontal lines, fix the cemented carbide 2 on the worktable, and select the worktable moving speed as 2mm / s, the parameters of laser rough milling are set to repetition frequency 50Hz, laser pulse width 0.5ms, considering the melting point and thermal conductivity of cemented carbide are relatively high, the laser ene...

Embodiment 2

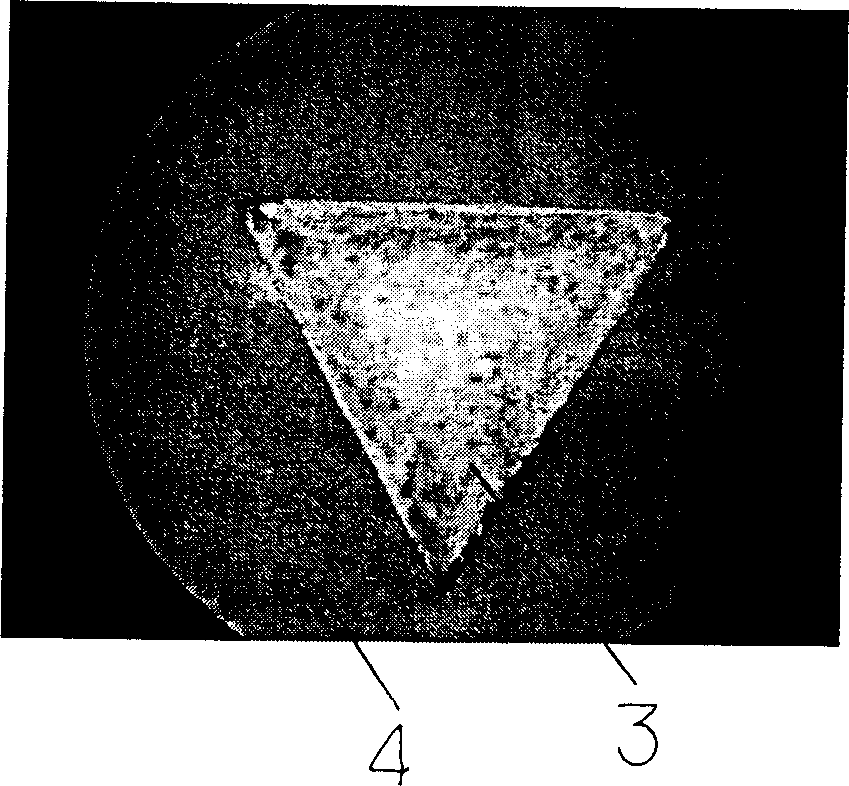

[0027] see image 3 , to the widely used Al 2 o 3 The processing of engineering ceramics 4 is taken as an example. Ceramics are substances combined by covalent bonds, ionic bonds or a mixture of the two. At room temperature, they have great resistance to shear stress deformation and high hardness. Because the ceramic crystal ions are combined by chemical bonds, the ceramics show great brittleness. It is precisely because of these characteristics of ceramics that ceramics are typical difficult-to-machine materials for conventional processing methods. In particular, it is very difficult to process components with high precision and complex shapes. The increase in the cost of finishing has seriously hindered the popularization and application of fine ceramics, so the subsequent processing of fine ceramics often becomes the key to its engineering application.

[0028] In this example, for Al 2 o 3 The milling process of engineering ceramics 4 is also to first draw the millin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com