Controllable liquid flow-vibration coupling auxiliary laser milling and polishing machining method and system

An auxiliary laser and processing system technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as rapid changes, plasma exhaustion effects, and affecting laser energy absorption, so as to avoid microcracks and improve discharge chip characteristics and processing quality, and the effect of improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

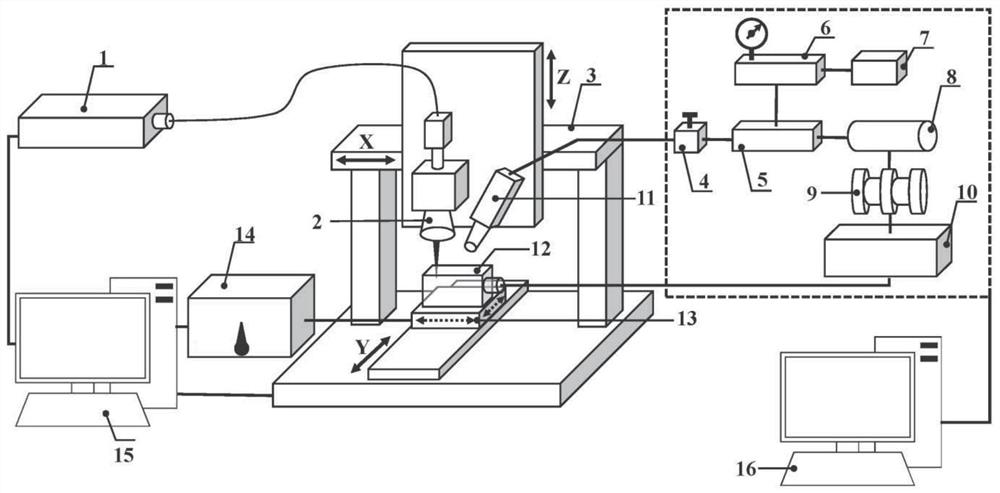

[0071] Example 1: See figure 1 , Which shows a controllable flow - vibrational coupling of laser assisted milling Polishing system, the processing system may also be designated as a controlled jet - vibration coupling aid milling Polishing laser system comprising a laser machining unit, stream auxiliary unit, the auxiliary vibrating unit, the motion control unit and the auxiliary unit.

[0072] Wherein the laser processing unit mainly includes cooperating fiber laser 1 and the laser processing head, the laser processing head 2 includes a scanning galvanometer, for a workpiece processing zone is provided in the laser processing.

[0073] Wherein, the exercise assisting unit 3 includes a motion platform, the workpiece may be provided on the moving platform 3, and the laser processing head 3 is also connected to the moving platform. The motion platform 3 at least drive the laser machining head and the workpiece in a three dimensional coordinate system in the X, Y, Z three directions ...

Embodiment 2

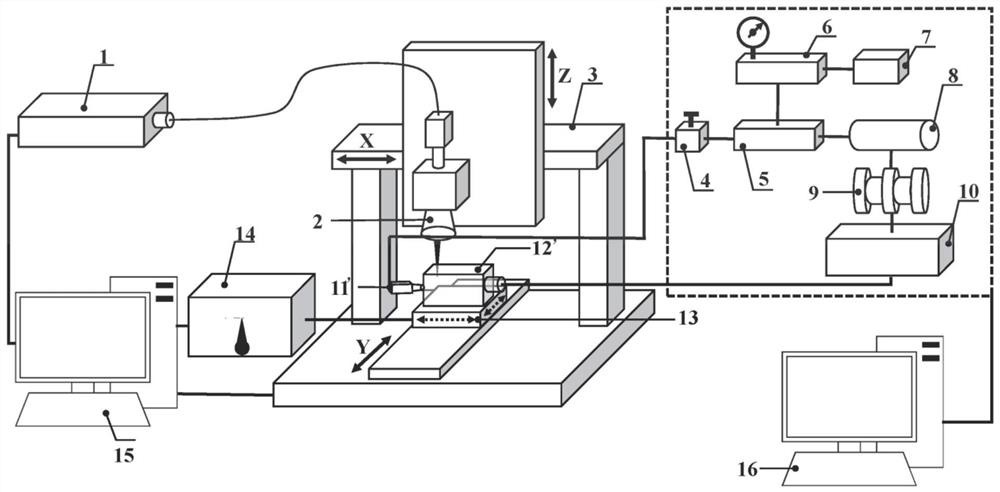

[0088] Example 2: See figure 2 , Shown therein a controlled flow - vibrational coupling of laser assisted milling Polishing system is substantially the same as in Example 1, with the difference that: wherein the auxiliary unit includes a stream flow rate control valve 4, a controller 5, the pressure sensor 6 , turbocharger 7, an accumulator 8, a pump 9, water tank 10, the flow channel controller 11 ', the closed auxiliary flow static process vessel 12' is provided in the flow line and between these devices and the like. Wherein, the water tank 10 for supplying water or other liquid. The outlet 10 of the water tank sequentially through the pump 9, an accumulator 8, the controller 5, a flow regulating valve 4, the flow channel controller 11 'of the closed auxiliary flow static process vessel 12' in communication. The closed auxiliary flow static process vessel 12 'may be provided in the processing area, and the workpiece 12 can be fixed to clamp the closed auxiliary flow static proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com