Liquid-state in-situ corrosion fatigue device and testing method

A corrosion-fatigue, in-situ technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem of collecting the surface strain field or fatigue crack propagation of the sample, and the adaptability of samples with different shapes needs to be improved. Real-time information collection of samples is difficult and other problems, to achieve the effect of easy processing and assembly, good analysis accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention are described in detail below in conjunction with technical solutions and accompanying drawings:

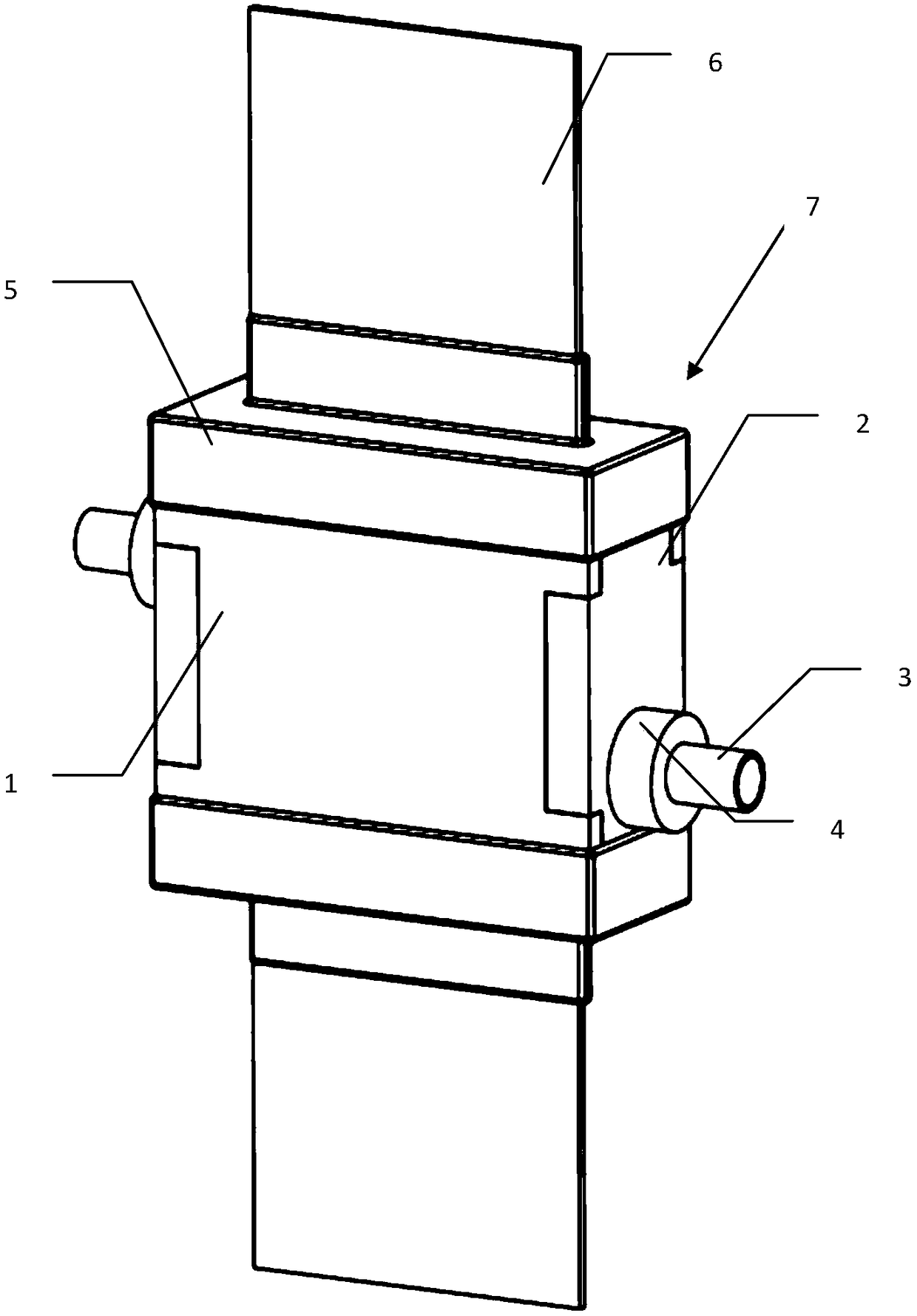

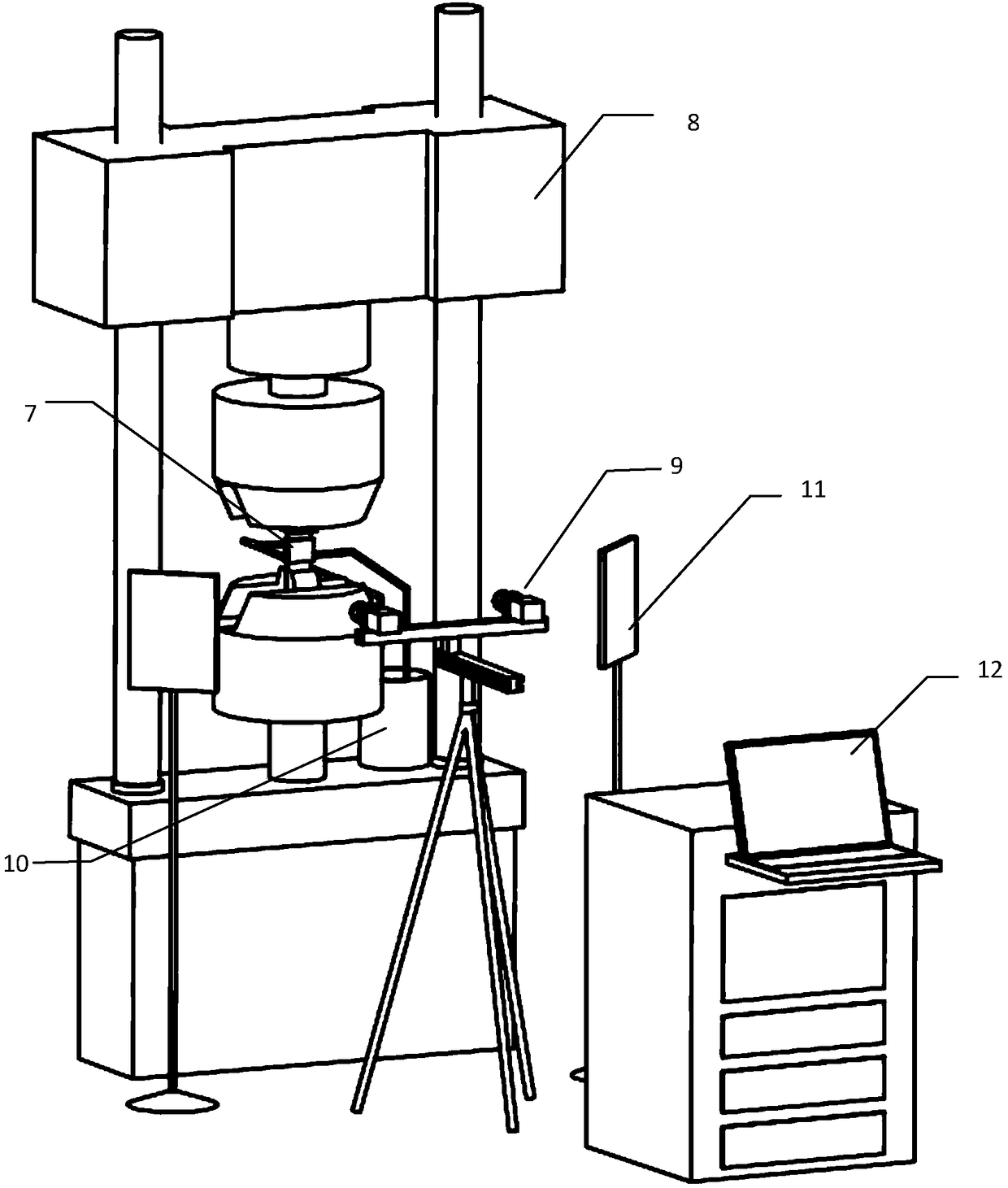

[0027] Such as figure 1 As shown, the liquid in-situ corrosion fatigue device 7 provided by the present invention includes a panel 1, a side plate 2, a conduit 3, a fixed platform 4 and a seal 5; wherein two panels 1 are arranged in parallel in the vertical direction; the two side panels 2 are respectively It is connected to the two side edges of two panels 1, thereby forming the main body of the device with a corrosion cavity formed inside; two seals 5 are respectively installed at the upper and lower ends of the main body of the device, and the middle part of each seal 5 is along the surface of the panel 1. A strip-shaped sample socket is formed in the direction; a conduit 3 is installed on each side plate 2 through a fixed table 4, the inner end of the conduit 3 passes through the side plate 2 and communicates with the corrosion cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com