Sampling device for exhaust particles of engine

A sampling device and engine technology, which is applied in the direction of exhaust device, electric control of exhaust treatment device, engine components, etc., can solve the problem that the amount of particle sampling does not meet the requirements of particle analysis, the experimental workload and energy waste, and the continuous filter paper cannot be realized. Replacement and other issues, to achieve the effect of reducing the experimental workload, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

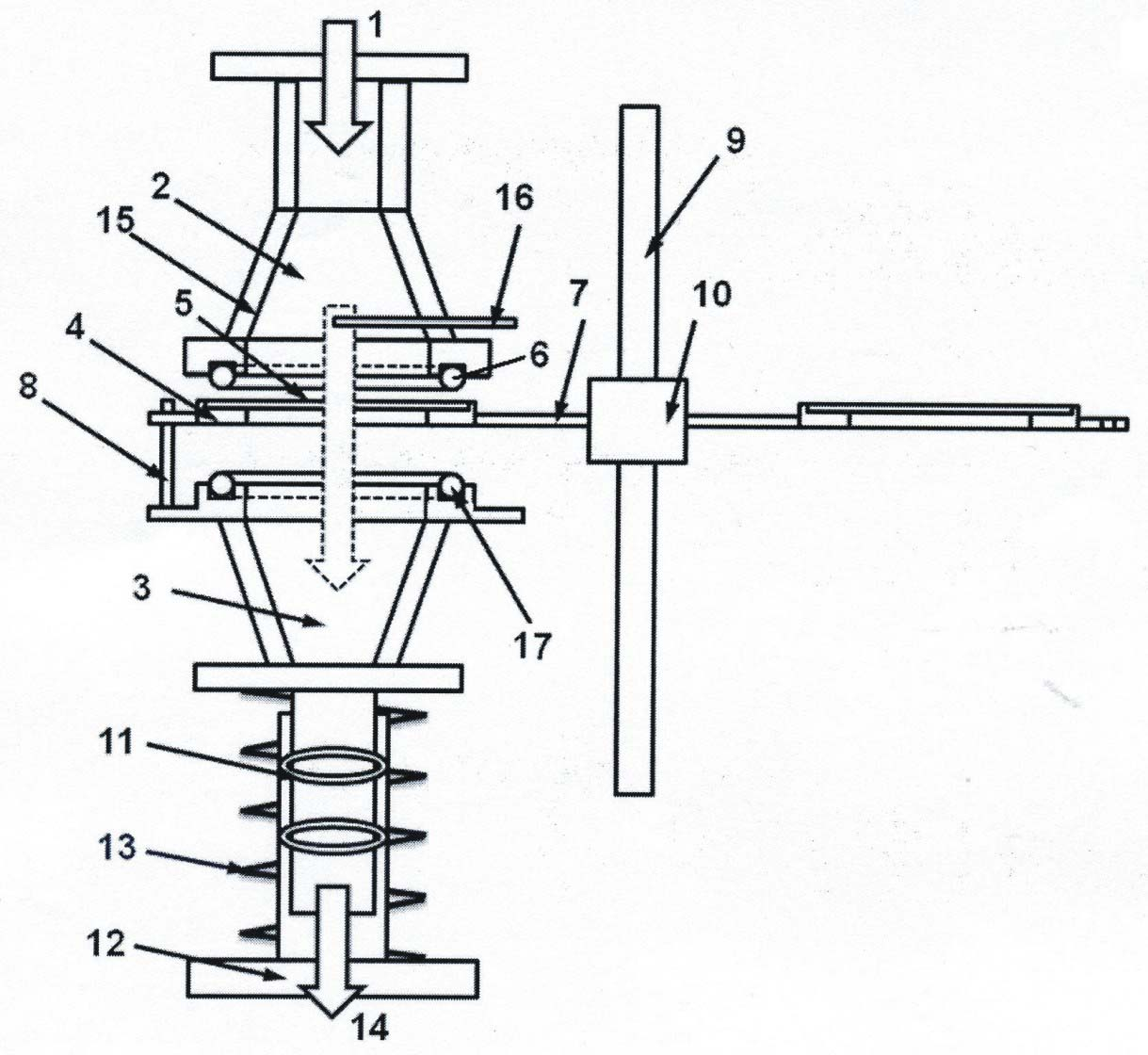

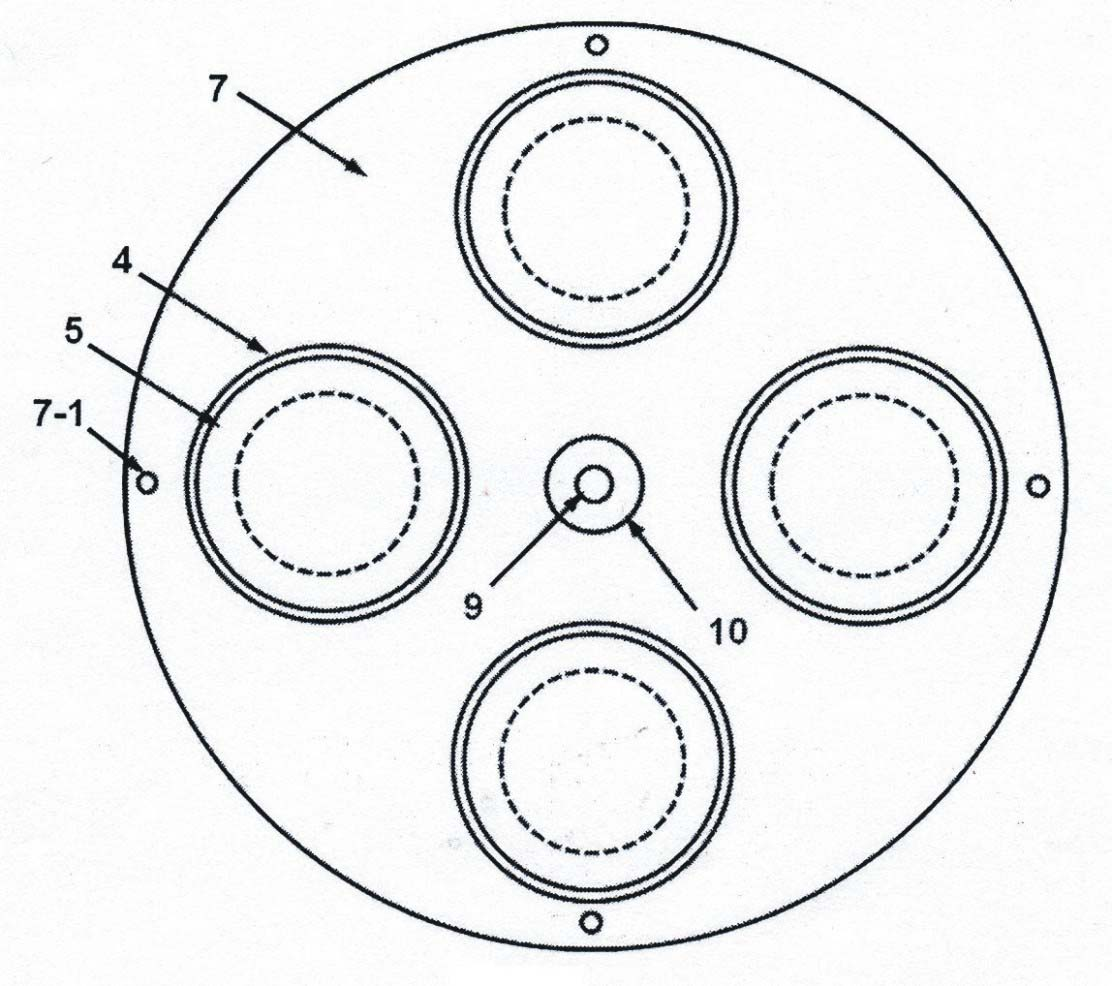

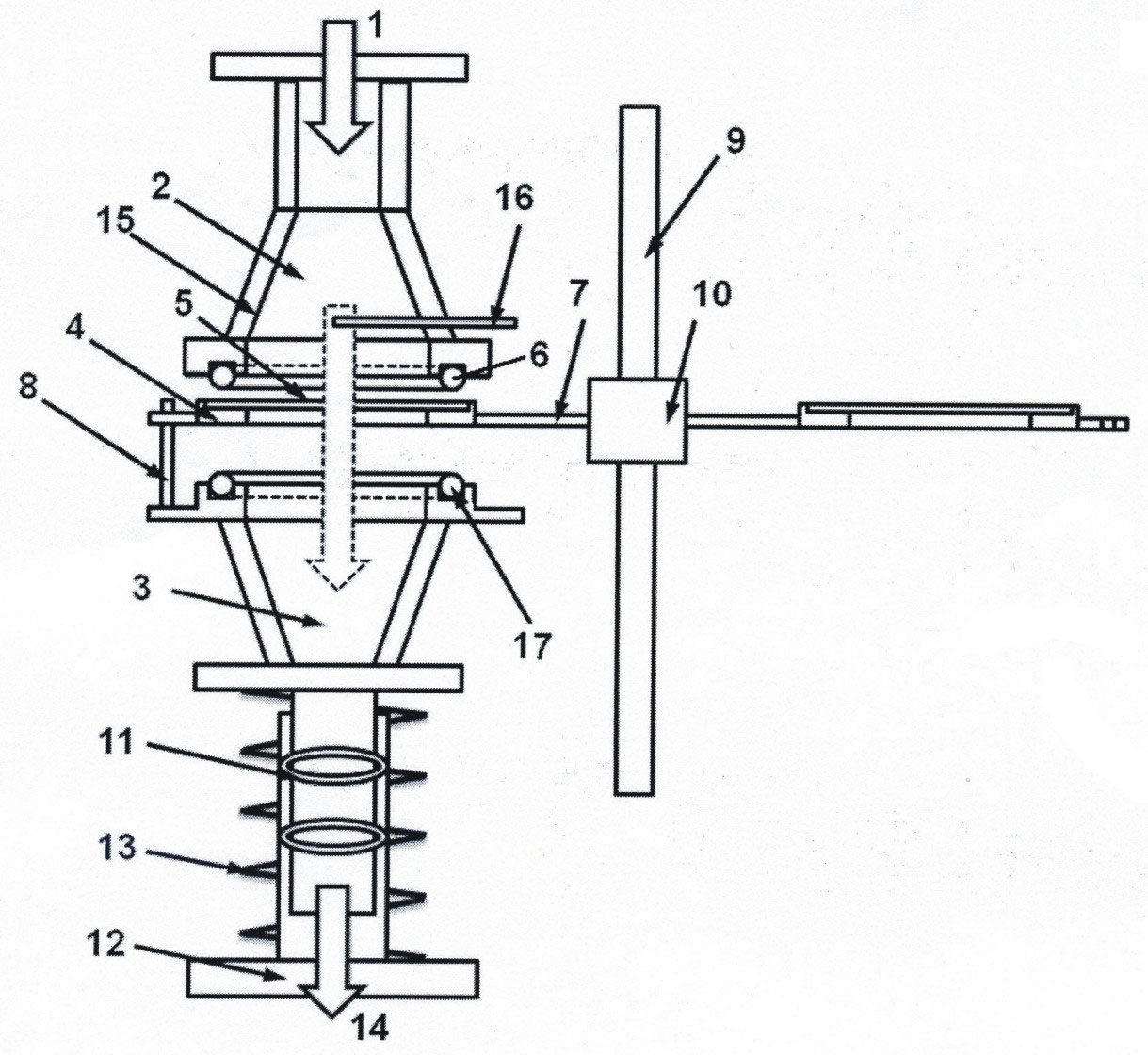

[0022] figure 1 Middle: 1. Entrance; 2. Upper cover; 3. Lower cover; 4. Filter paper mounting plate; 5. Filter paper; 6. Upper cover filter paper O-ring seal; 7. Turntable; 8. Positioning pin; 9. Fixed shaft; 10. Bearing; 11. O-shaped sealing ring; 12. Base casing; 13. Spring; 14. Outlet; 15. (upper and lower cover) heating insulation layer; 16. Temperature sensor. 17. O-ring of filter paper under the cover.

[0023] figure 1 It is shown that the engine exhaust particulate sampling device is fixed on the frame with the upper cover 2 used to introduce engine exhaust gas, and the upper cover filter paper O-ring 6 is arranged in the groove on the lower end surface of the upper cover to discharge the engine The lower cover 3 of the exhaust gas is located directly below the upper cover, the pipe section at the lower part of the lower cover extends into the base sleeve 12 in a sliding fit, and an O-ring 11 is arranged between the lower pipe section of the lower cover and the base sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com