Nitrogen-doped graphene, Pd-loaded nitrogen-doped graphene catalyst and preparation method and application thereof

A graphene and catalyst technology, applied in aza-graphene catalyst and preparation thereof, in the field of aza-graphene, can solve problems such as expensive price, restricting large-scale practical application, harsh preparation conditions, etc., achieving easy content, mild conditions, Easy to wash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention provides a kind of preparation method of azagraphene, comprises the following steps;

[0023] (1), GO is added to a certain amount of water, and treated in an ultrasonic generator for 1-3h; the mass volume ratio of the GO to water is (10-90)mg:(10-80)mL;

[0024] (2), then transferred to the reaction kettle, stirred and reacted at 150-200°C for 5-24h;

[0025] (3) Vacuum drying at 30-60° C. for 12-24 hours after suction filtration and washing to obtain sample RGO.

[0026] Further, the preparation method of azagraphene as described above also needs to add urea in step 1, specifically:

[0027] Treat GO with a certain amount of urea and water in an ultrasonic generator for 1-3 hours, and finally get the sample NRGO -x , the mass volume ratio of GO, urea, and water is: A mg:B g:C mL, wherein, 10≤A≤90, 0<B≤27, 10≤C≤80, and x represents urea and oxidation Graphene mass ratio, 0<X<300.

[0028] Further, the preparation method of azagraphene as descr...

Embodiment 1

[0035] Preparation of Graphene Oxide (GO)

[0036] 1) Add an appropriate amount of 98% concentrated sulfuric acid into a 500mL beaker, and control the temperature to 0°C.

[0037] 2) Add 10g of graphite powder and 5g of sodium nitrate, and stir for 1h.

[0038] 3) Add 30 g of potassium permanganate powder under vigorous stirring (the addition speed should be well controlled, and it is best not to make the temperature exceed 20° C.).

[0039] 4) Remove the low-temperature ice bath, and stir in a water bath at 35°C for 30 min.

[0040] 5) Add 460mL of deionized water under stirring, raise the temperature of the reaction solution to about 98°C, and continue stirring for 1h.

[0041] 6) Dilute the reaction solution with 1.4L deionized warm water, and then add a certain amount of 3% hydrogen peroxide solution.

[0042] 7) Filtrate while it is hot, and fully wash the filter cake with a pre-prepared 5% hydrochloric acid aqueous solution (warm) until there is no sulfate ion in the ...

Embodiment 2

[0045] Preparation process of nitrogen-doped graphene

[0046] (1) GO (containing about 81 mg C) and a certain amount of urea were added to 70 mL of water, and treated in an ultrasonic generator (200 W) for 3 h.

[0047] (2) Then transfer to a 100mL reactor and stir the reaction at 180°C for 10h.

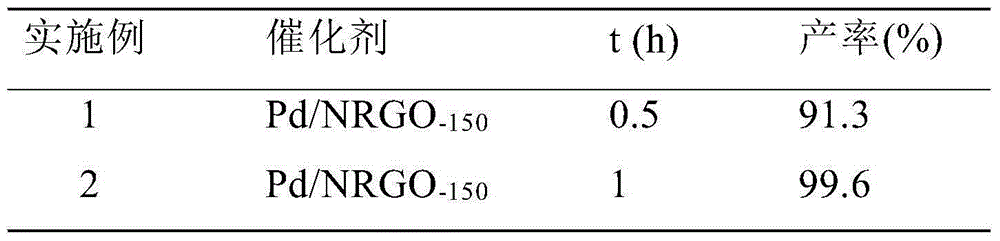

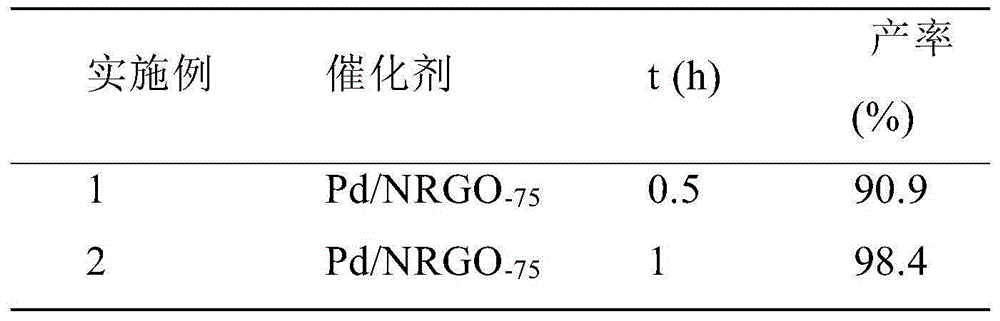

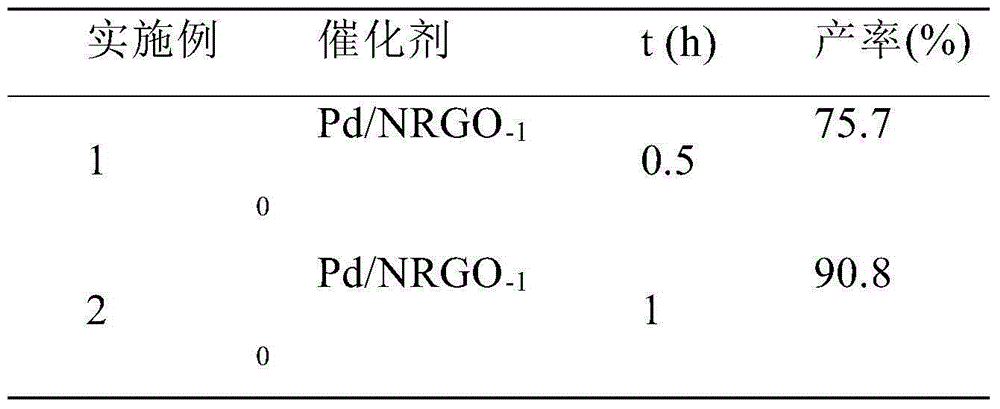

[0048] (3) Vacuum-dry at 30° C. for 12 hours after suction filtration and washing. Label this sample as NRGO -x(x represents the weight ratio of urea and GO = 10, 75, 150, 300, etc.), adjusting the value of x can produce azagraphene with different nitrogen contents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com