Method for efficient carbonation and harmless treatment of waste incineration fly ash

A technology of waste incineration fly ash and carbonation, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of high safety hazards, complex equipment, high energy consumption, and achieve safe operation and disposal costs. The effect of low and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

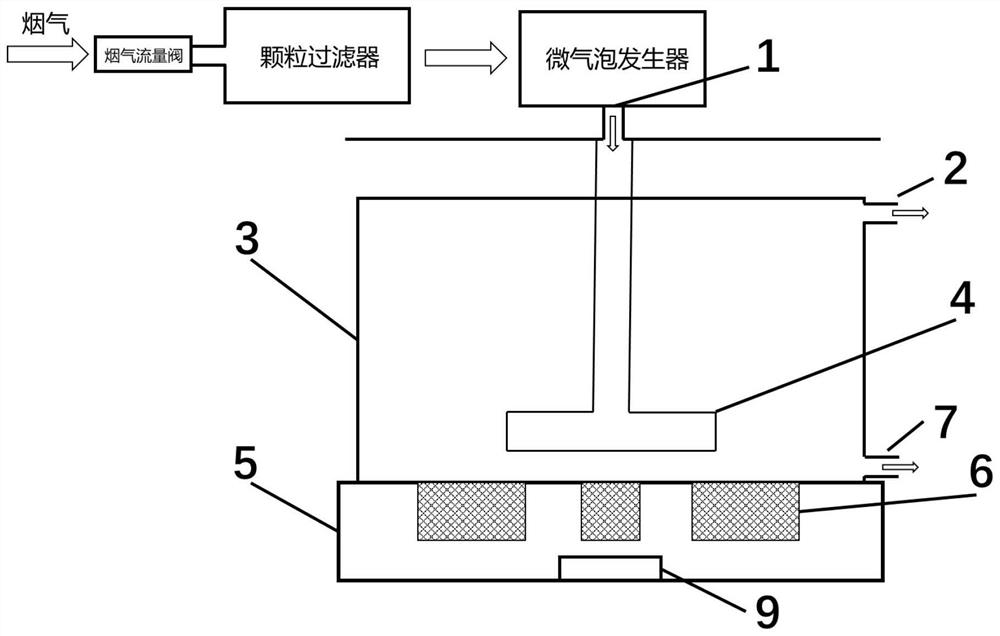

[0047] (1) Take 10kg of fly ash in the bag filter in the domestic waste incineration power plant and pour it into the reactor, and choose a liquid-solid ratio of 5:1 (L / kg), pour 50L of tap water into the reactor, and water- Ash mixed solution is stirred;

[0048] (2) Pass the flue gas (with a carbon dioxide content of 8% to 15%) of the waste incineration power plant into the particle filter, and set the gas flow rate to 200L / min, then pass the gas from the particle filter into the microbubble generator to generate microbubbles. bubble;

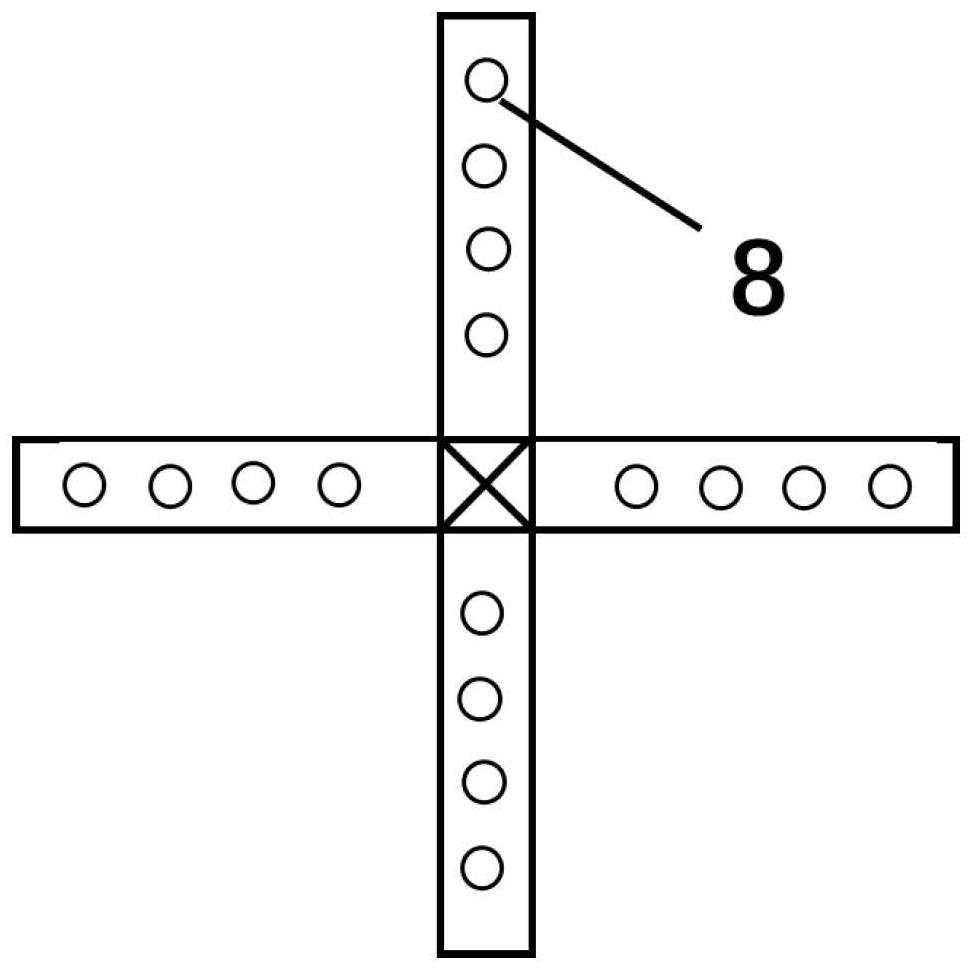

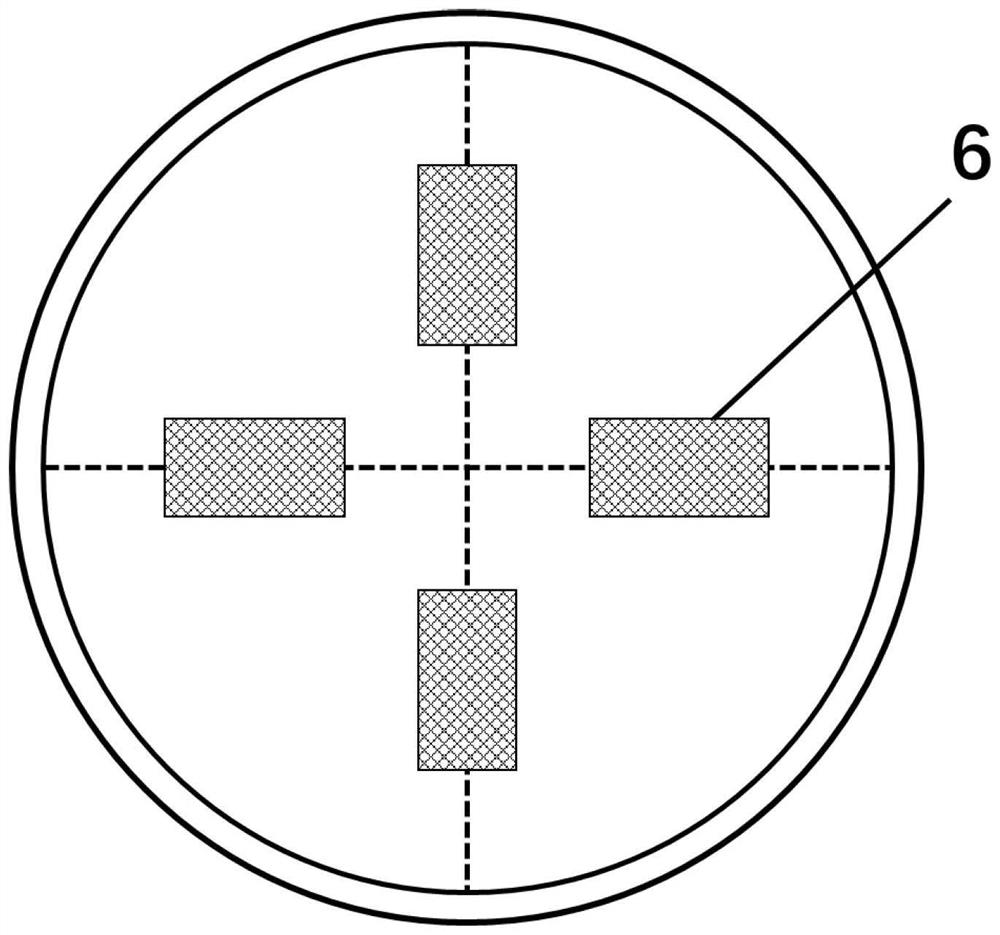

[0049] (3) Turn on the ultrasonic transducer, set the ultrasonic frequency range to 28kHz, pass the prepared microbubbles into the reactor through the microbubble inlet on the upper end of the stirrer, turn on the stirrer, adjust the stirring rate to 30rpm, and the gas passes through the stirrer paddle The micro-bubbles on the leaf exit into the reaction solution and react with the alkaline substances (calcium hydroxide, basic calcium chlori...

specific Embodiment 2

[0053] (1) Take 10kg of fly ash in the bag filter in the domestic waste incineration power plant and pour it into the reactor, and choose a liquid-solid ratio of 8:1 (L / kg), pour 80L of tap water into the reactor, and water- Ash mixed solution is stirred;

[0054] (2) Pass the flue gas (with a carbon dioxide content of 8 to 15%) from a coal-fired power plant into the particle filter, set the gas flow rate to 250L / min, and then pass the gas from the particle filter into the microbubble generator to generate microbubbles. bubble;

[0055] (3) Turn on the ultrasonic transducer, set the ultrasonic frequency range to 35kHz, pass the prepared microbubbles into the reactor through the microbubble inlet on the upper end of the stirrer, turn on the stirrer, adjust the stirring rate to 50rpm, and the gas passes through the stirrer paddle The micro-bubbles on the leaf exit into the reaction solution and react with the alkaline substances (calcium hydroxide, basic calcium chloride, etc.)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com