Layered ternary cathode material of lithium ion battery and microwave preparation method of layered ternary cathode material

A lithium-ion battery and cathode material technology, applied in battery electrodes, electrical components, secondary batteries, etc., can solve problems such as poor anti-overcharge ability, large environmental pollution, and poor cycle performance, and achieve fast response and low equipment requirements. High, small particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

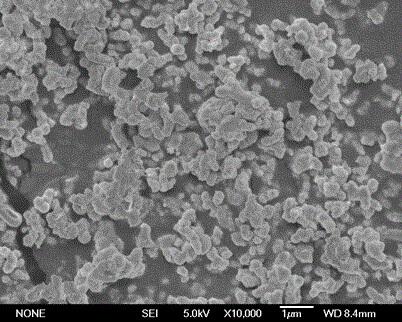

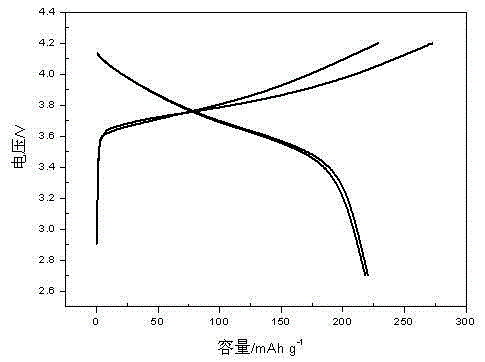

[0022] First weigh 3mol of lithium acetate, 1mol of nickel acetate, 1mol of cobalt acetate, 1mol of butyl titanate and 6mol of citric acid, add 2ml of water, grind for 10 minutes and mix well, then put the mixture in a crucible and put it in a household microwave oven, and set it on medium-high heat Heating under the gear for 10 minutes, taking it out after natural cooling, and grinding to obtain a black layered ternary cathode material LiNi with a particle size of 200-500nm 1 / 3 co 1 / 3 Ti 1 / 3 o 2, The household microwave oven used in this embodiment is a Galanz brand WD900SL23-2 microwave oven.

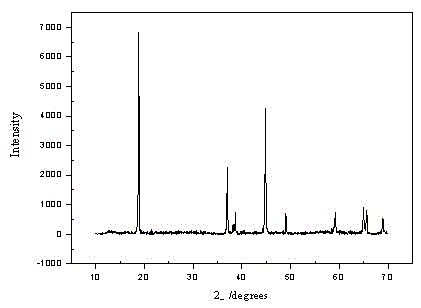

[0023] see figure 1 , figure 1 It is the layered ternary cathode material LiNi prepared in this embodiment. 1 / 3 co 1 / 3 Ti 1 / 3 o 2 The X-ray diffraction pattern. Depend on figure 1 It can be seen that the phase obtained in this example is a typical α-NaFeO 2 Hexagonal layered structure without any miscellaneous peaks appearing. The sharp peak shape indicated that the result...

Embodiment 2

[0029] First weigh 3mol of lithium acetate, 1mol of nickel acetate, 1mol of cobalt acetate, 1mol of butyl titanate and 6mol of citric acid, add 2ml of water and grind for 15 minutes to mix evenly, then put the mixture in a crucible and put it in a household microwave oven. Heating under the gear for 20 minutes, taking it out after natural cooling and grinding to obtain a black layered ternary cathode material LiNi with a particle size of 200-500nm 1 / 3 co 1 / 3 Ti 1 / 3 o 2, The household microwave oven used in this embodiment is a Galanz brand WD900SL23-2 microwave oven.

[0030] The layered ternary positive electrode material prepared in this example was subjected to X-ray diffraction, electron microscope scanning, and charge-discharge tests, and the spectra obtained were almost the same as those obtained in Example 1.

Embodiment 3

[0032] First weigh 3mol of lithium acetate, 1mol of nickel acetate, 1mol of cobalt acetate, 1mol of butyl titanate and 6mol of citric acid, add 2ml of water, grind for 10 minutes and mix well, then put the mixture in a crucible and put it in a household microwave oven, and set it on medium-high heat Heating under the gear for 30 minutes, taking it out after natural cooling, and grinding to obtain a black layered ternary cathode material LiNi with a particle size of 200-500nm 1 / 3 co 1 / 3 Ti 1 / 3 o 2, The household microwave oven used in this embodiment is a Galanz brand WD900SL23-2 microwave oven.

[0033] The layered ternary positive electrode material prepared in this example was subjected to X-ray diffraction, electron microscope scanning, and charge-discharge tests, and the spectra obtained were almost the same as those obtained in Example 1.

[0034] As can be seen from Examples 1-3, under the premise that the metering ratio is the same and the selected raw materials are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com