Preparation method and application of ganoderma amboinense extract

An extract and antler technology, applied in the field of preparation of antler Ganoderma lucidum extract, can solve the problems of difficulty in collecting the final product, heat loss of the extract, low content of active substances, etc., and achieve the effect that the extraction process is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation of the extract of embodiment 1 staghorn ganoderma lucidum

[0025] Take the dried staghorn ganoderma fruiting bodies, chop them, pass through a 80-mesh sieve, weigh 10g of staghorn ganoderma fruiting body powder, and disperse the staghorn ganoderma fruiting bodies in 100mL 70-90°C according to the liquid-to-material ratio of 10:1 (mL / g) In distilled water, mix evenly, use an ultrasonic crusher: JY92-IIN type, 700W ultrasonic crushing for 1 hour, then filter, extract the filter cake with water for later use, add 5 times the volume of ethanol to the filtrate of the water extraction, stir, and let it settle at 4°C , filter to obtain the alcohol precipitation filter cake as the first extract;

[0026] Concentrate the alcohol precipitation filtrate and combine it with the water-extracted filter cake, add distilled water according to the liquid-to-solid ratio of 15:1 (mL / g), adjust the pH value to 5.6 with citric acid buffer, and add fiber at 20% of the weight...

Embodiment 2

[0027] The preparation of the extract of embodiment 2 staghorn ganoderma

[0028] Take the dried staghorn ganoderma fruiting bodies, chop them, pass through a 50-mesh sieve, weigh 10g of staghorn ganoderma fruiting body powder, and disperse the staghorn ganoderma fruiting bodies in 150mL of 70-90°C distilled water according to the liquid-to-material ratio of 15:1 (mL / g) Medium, mix evenly, use an ultrasonic crusher: JY92-IIN type, 500W ultrasonic crushing for 1.5 hours, then filter, extract the filter cake with water for later use, add 8 times the volume of ethanol to the filtrate from the water extraction, stir, and let it settle at 4°C. Filtration to obtain the alcohol precipitation filter cake is the first extract;

[0029] Concentrate the alcohol precipitation filtrate and combine it with the water extraction filter cake, add distilled water according to the liquid-to-solid ratio of 25:1 (mL / g), adjust the pH value to 5.6 with citric acid buffer solution, and add papaya in...

Embodiment 3

[0030] Embodiment 3 extraction rate experiment

[0031] 3.1 Extraction rate experiment of β-glucan

[0032] The yield of β-glucan was determined by the Congo red method.

[0033] β-glucan yield (mg / g) = β-glucan mass (mg) / raw material mass (g)

[0034] 3.2 Extraction rate experiment of Ganoderma lucidum triterpenes

[0035] The methanol solutions of ganoderma acid A and ganoderma acid B were used as reference substances, and were detected by high performance liquid chromatography. The extraction rate of staghorn ganoderma lucidum triterpenes is calculated based on the sum of the content of ganoderma acid A and ganoderma acid B, and the calculation formula is:

[0036] Extraction rate=(content of ganoderma acid A+content of ganoderma acid B)×volume of extraction solution / mass of raw material.

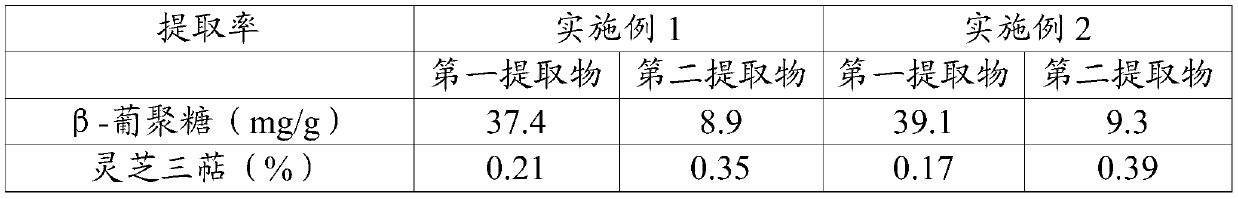

[0037] 3.3 The experimental results of extraction rate are as shown in Table 1. On the one hand, two groups of extracts can be obtained by adopting the method of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com