Preparation method and application of tobacco extract

A technology for tobacco extract and tobacco powder, applied in the application, tobacco, tobacco processing and other directions, can solve the problems of unsatisfactory tobacco extract quality, heating reflux and concentration loss, low extraction yield, etc., and achieves a simple and easy extraction process. , Keep the original taste and the effect of mild extraction process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

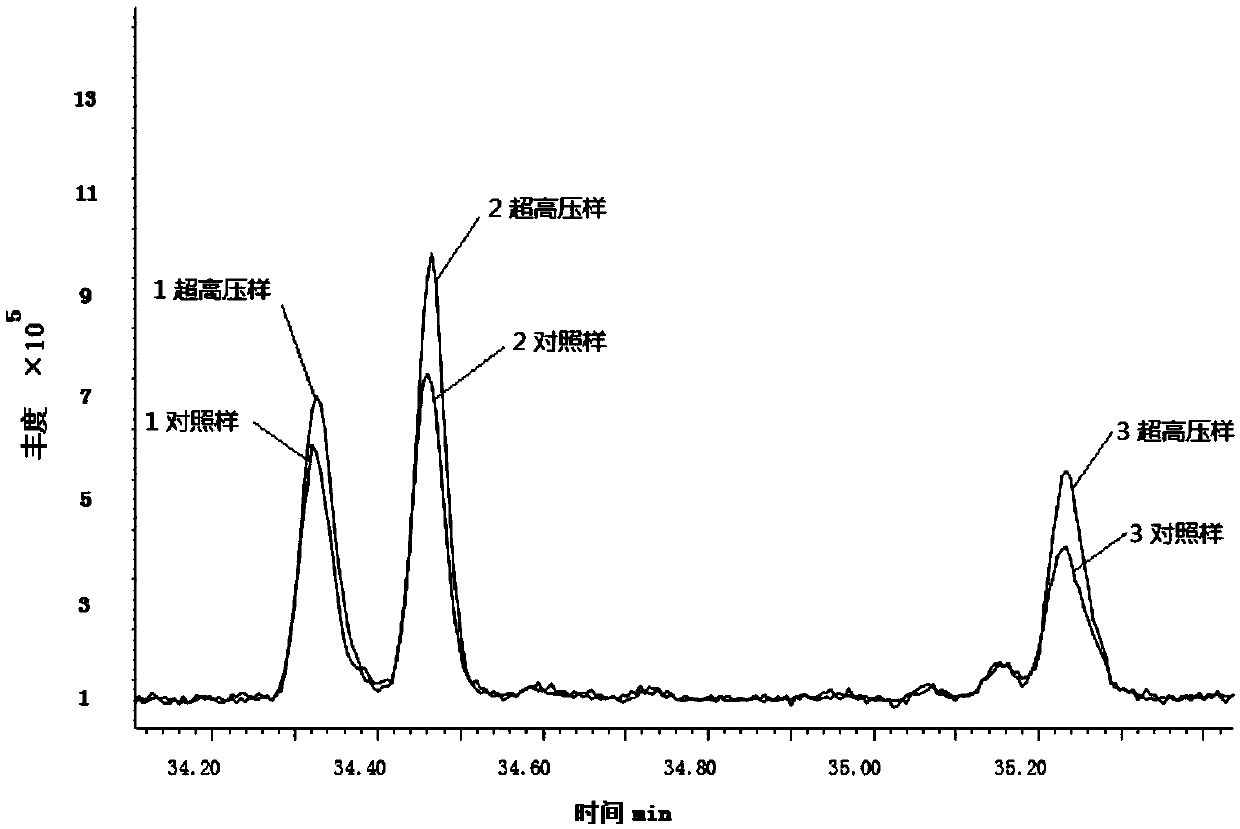

[0024] Make a control sample and a test sample for a comparative experiment: cut 100g of Yunnan Dali C2F fragrance single-material tobacco into shreds, and grind it into 80-mesh tobacco powder with a ball mill, disperse it with 9900g caprylic acid glyceride, and disperse it into a uniform mixture by rotating at a high speed. The suspension was weighed and divided into four parts, respectively marked as 1#, 2#, 3#, 4# sample, 1# was used as the control sample, 2# was subjected to high-pressure homogenization treatment, 3# was subjected to ultra-high pressure treatment, 4# The samples were subjected to ultra-high pressure treatment and then high-pressure homogenization treatment. The specific operation is as follows: Ultra-high pressure treatment Put the dispersion liquid into a sealed bag for vacuum sealing, place it in the water medium at room temperature, keep the ultra-high pressure at 300MPa for 30 minutes, and then release the pressure. High-pressure homogeneous treatment ...

Embodiment 2

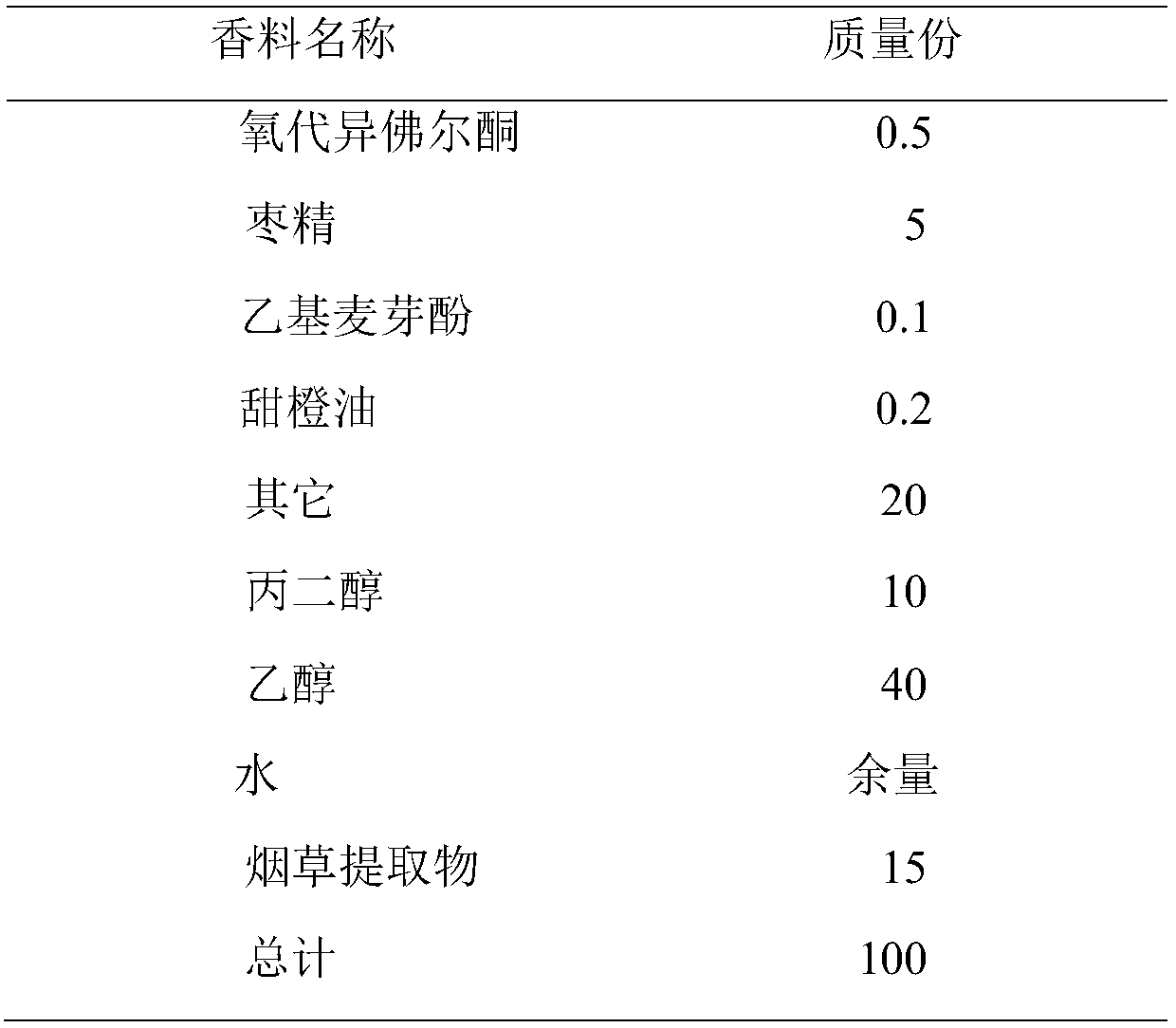

[0026] Grind 250g of Hexiaye group into 100-mesh smoke powder with a ball mill, disperse with 4750g of ethanol aqueous solution (50% mass ratio), disperse into a uniform suspension by high-speed rotation, and treat at room temperature for 25min with 250MPa ultra-high pressure , release the pressure, and the dispersion is subjected to high-pressure homogenization treatment again, homogenized 15 times, the homogenized pressure is gradually increased from 10MPa to 150MPa, and the homogenized components are placed in a low-temperature cooling cycle at -10°C to -20°C, homogenized After completion, the supernatant liquid was poured, and the lower layer containing a small amount of suspended matter was centrifuged to obtain the supernatant liquid, and the supernatant liquid was combined, and 2 g of the extract was taken, and the aroma was manually added to 100 g of Baisha high-quality shredded tobacco with a throat sprayer, and the balance was maintained for 2 hours. According to sens...

Embodiment 3

[0028] Grind 250g of oriental tobacco with a ball mill into smoke powder with a mesh number of 100, disperse with 4750g of ethanol aqueous solution (50% mass ratio), disperse into a uniform suspension by high-speed rotation, treat at room temperature for 25min with an ultra-high pressure of 400MPa, discharge pressure, and the dispersion liquid is subjected to high-pressure homogenization treatment, homogenization 15 times, the homogenization pressure is gradually increased from 10MPa to 150MPa, the homogenization component is placed in a low-temperature cooling cycle at -10°C to -20°C, and the homogenization is completed. The supernatant was poured, and the lower layer containing a small amount of suspended solids was centrifuged to take the supernatant, combined the supernatant, took 2g of oriental tobacco extract, and manually added flavor to 100g of Baisha fine cut tobacco with a throat sprayer, and equilibrated for 2 hours. After sensory evaluation, the characteristic aroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com