Method for recycling NH3-N from ammoninted waste liquid

A recovery method and low-radioactivity technology, which is applied in the field of waste liquid treatment, can solve problems such as pollution, radioactive substances escaping, and increased energy consumption, and achieve the effects of compact process flow, reduced water replenishment, and improved recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

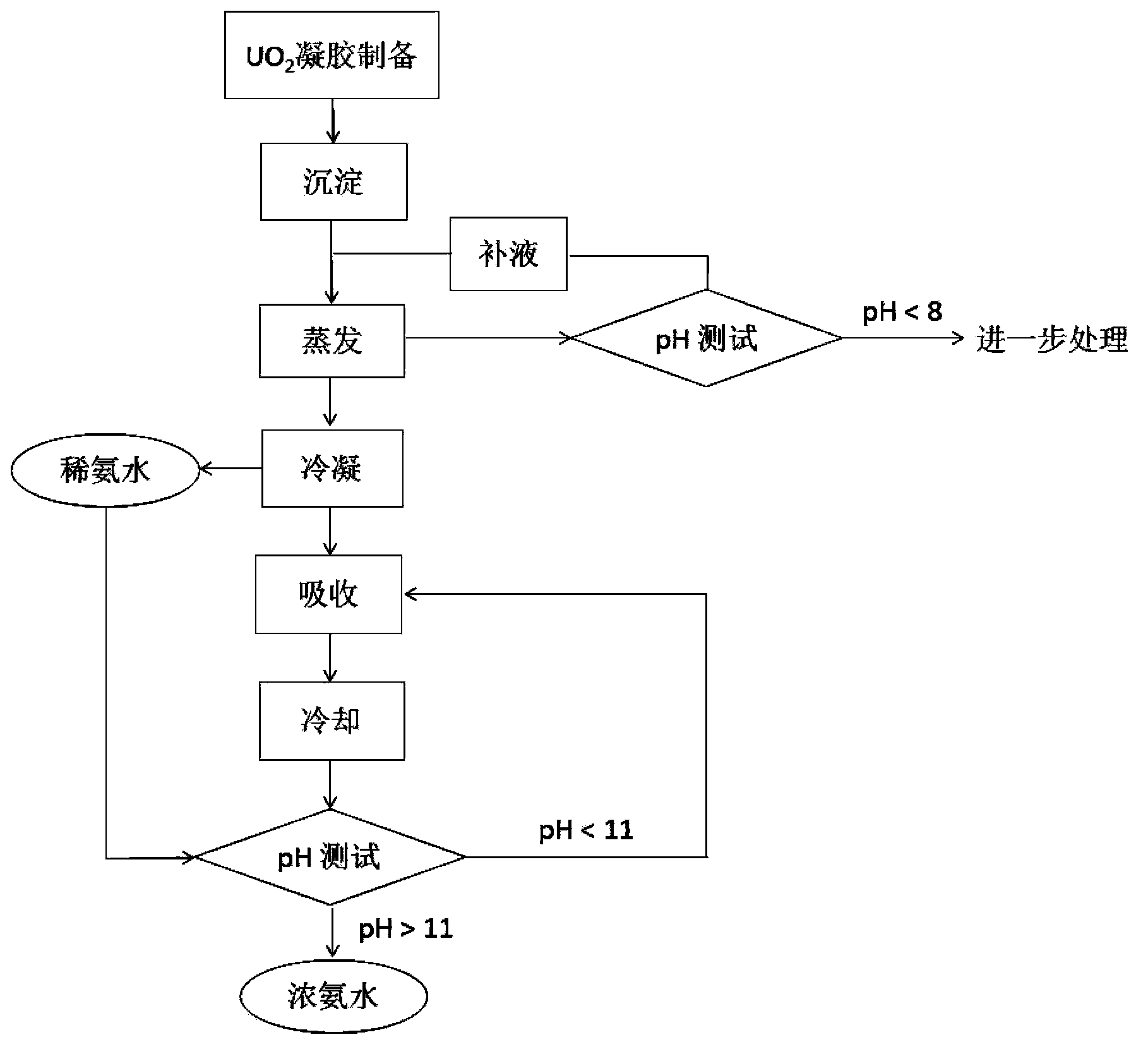

[0034] During the production of a batch of fuel elements, about 250 liters of ammonia-containing process waste liquid needs to be treated. NH in raw water 3 -N mass concentration is 8.9%, the main radioactive substance is uranium 235, the concentration is about 10ppm. In order to realize the removal and recovery of ammonia in wastewater and avoid the secondary pollution of radioactive uranium 235, the mode of intermittent heating and intermittent feeding is used to recover ammonia by distillation. The whole process is shown in figure 1 As shown, the specific process is as follows:

[0035] (1) The ammonia-containing process waste liquid is left standing in the waste liquid tank. After the solid matter in the waste liquid is precipitated, the supernatant liquid is sent to the heat exchanger by a pump. After heat exchange to increase the temperature, it is pumped into the evaporator for heating.

[0036] (2) First pump two-thirds of the volume of feed liquid into the evaporatin...

Embodiment 2

[0042]During the production of a certain batch of fuel elements, about 200 liters of ammonia-containing process waste liquid needs to be treated. NH in raw water 3 -N mass concentration is 5.3%, the main radioactive substance is uranium 235, the concentration is about 10ppm. In order to realize the removal and recovery of ammonia in wastewater and avoid the secondary pollution of radioactive uranium 235, the mode of intermittent heating and intermittent feeding is used to recover ammonia by distillation. The whole process is shown in figure 1 As shown, the specific process is as follows:

[0043] (1) The ammonia-containing process waste liquid is left standing in the waste liquid tank. After the solid matter in the waste liquid is precipitated, the supernatant liquid is sent to the heat exchanger by a pump. After heat exchange to increase the temperature, it is pumped into the evaporator for heating.

[0044] (2) First pump two-thirds of the volume of feed liquid into the eva...

Embodiment 3

[0050] During the production of a certain batch of fuel elements, about 200 liters of ammonia-containing process waste liquid needs to be treated. NH in raw water 3 -N mass concentration is 7.8%, the main radioactive substance is uranium 235, the concentration is about 10ppm. In order to realize the removal and recovery of ammonia in wastewater and avoid the secondary pollution of radioactive uranium 235, the mode of intermittent heating and intermittent feeding is used to recover ammonia by distillation. The whole process is shown in figure 1 As shown, the specific process is as follows:

[0051] (1) The ammonia-containing process waste liquid is left standing in the waste liquid tank. After the solid matter in the waste liquid is precipitated, the supernatant liquid is sent to the heat exchanger by a pump. After heat exchange to increase the temperature, it is pumped into the evaporator for heating.

[0052] (2) First pump one-third of the volume of feed liquid into the eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com