Preparation method of single-layer MXene nanosheet/ZIF-67 composite material

A ZIF-67, composite material technology, applied in the fields of materials science and electrochemistry, can solve problems such as limited exploration, and achieve the effect of simple method, easy access, and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

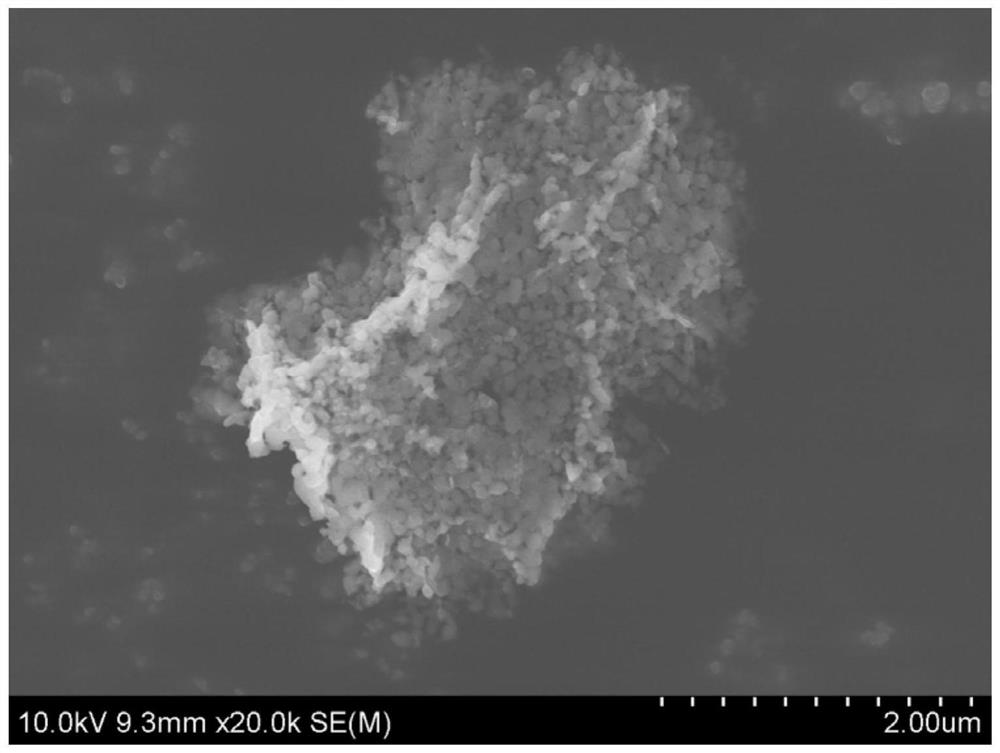

[0043] Preparation of monolayer MXene nanosheet / ZIF-67 composite:

[0044] (1) Take 60ml of hydrochloric acid solution with a concentration of 5.49mg / ml and 1g of lithium fluoride in a plastic container at 35°C and stir for 15min to dissolve to form hydrofluoric acid;

[0045] (2) 1g of titanium aluminum carbide (Ti 3 AlC 2 ) was slowly added to the above solution at the same temperature, and the aluminum layer was peeled off by etching for 48h;

[0046] (3) the reaction solution is centrifuged 6 times, the first 5 times of centrifugal rotation speed are 3500rpm, and the time is 5min, and the last centrifugal rotation speed is 5000rpm, and the time is 30min, and freeze-drying is obtained to obtain Ti 3 C 2 MXene;

[0047] (4) 400mg Ti 3 C 2 MXene was dispersed in 40 ml of deionized water, and ultrasonically treated at 30 kHz for 7 h at 5 °C under nitrogen atmosphere to obtain monolayer Ti 3 C 2 MXene solution;

[0048] (5) 20ml monolayer Ti 3 C 2 The MXene solut...

Embodiment 2

[0054] Preparation of monolayer MXene nanosheet / ZIF-67 composite:

[0055] (1) Take 60ml of hydrochloric acid solution with a concentration of 5.49mg / ml and 1g of lithium fluoride in a plastic container at 35°C and stir for 15min to dissolve to form hydrofluoric acid;

[0056] (2) 1g of titanium aluminum carbide (Ti 3 AlC 2 ) was slowly added to the above solution at the same temperature, and the aluminum layer was peeled off by etching for 48h;

[0057] (3) the reaction solution is centrifuged 6 times, the first 5 times of centrifugal rotation speed are 3500rpm, and the time is 5min, and the last centrifugal rotation speed is 5000rpm, and the time is 30min, and freeze-drying is obtained to obtain Ti 3 C 2 MXene;

[0058] (4) 400mg Ti 3 C 2 MXene was dispersed in 40 ml of deionized water, and ultrasonically treated at 30 kHz for 7 h at 5 °C under nitrogen atmosphere to obtain monolayer Ti 3 C 2 MXene solution;

[0059] (5) 20ml monolayer Ti 3 C 2 The MXene soluti...

Embodiment 3

[0062] Preparation of monolayer MXene nanosheet / ZIF-67 composite:

[0063] (1) Take 60ml of hydrochloric acid solution with a concentration of 5.49mg / ml and 1g of lithium fluoride in a plastic container at 35°C and stir for 15min to dissolve to form hydrofluoric acid;

[0064] (2) 1g of titanium aluminum carbide (Ti 3 AlC 2 ) was slowly added to the above solution at the same temperature, and the aluminum layer was peeled off by etching for 48h;

[0065] (3) the reaction solution is centrifuged 6 times, the first 5 times of centrifugal rotation speed are 3500rpm, and the time is 5min, and the last centrifugal rotation speed is 5000rpm, and the time is 30min, and freeze-drying is obtained to obtain Ti 3 C 2 MXene;

[0066] (4) 400mg Ti 3 C 2 MXene was dispersed in 40 ml of deionized water, and ultrasonically treated at 30 kHz for 7 h at 5 °C under nitrogen atmosphere to obtain monolayer Ti 3 C 2 MXene solution;

[0067] (5) 20ml monolayer Ti 3 C 2 The MXene soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com