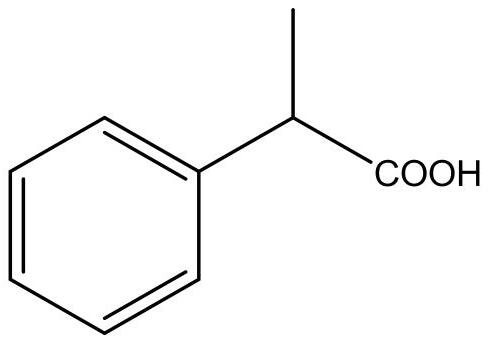

Method for electrochemically preparing 2-phenylpropionic acid

A phenylpropionic acid, electrochemical technology, applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve problems such as human damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

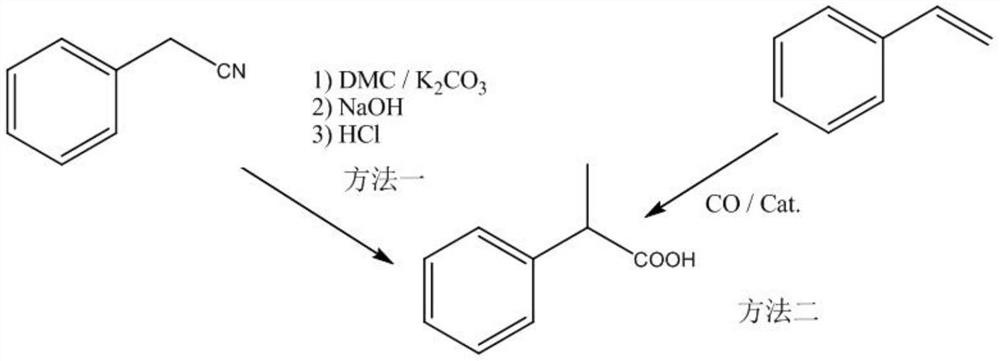

Problems solved by technology

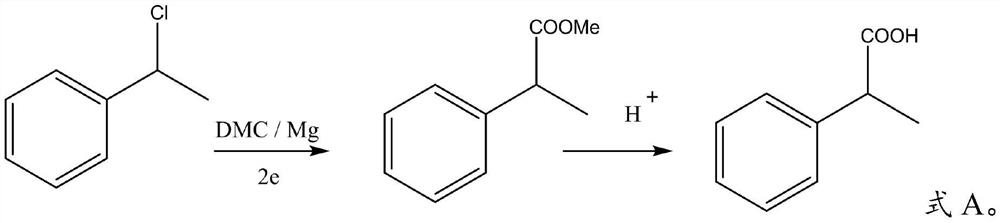

Method used

Image

Examples

Embodiment 1

[0050] Put 150 grams of 1-phenylchloroethane and 630 grams of dimethyl carbonate in the electrolytic cell equipped with magnesium electrodes and carbon electrodes, add 17.5 grams of tetrabutylammonium bromide, and control the temperature of the electrolytic cell at 35 °C , turn on the DC power supply, adjust the current value at 100-200mA, and continue the electrolysis reaction for 3 hours, and the conversion of 1-phenylchloroethane in the HPLC control is complete;

[0051]Transfer the electrolyte solution into a reaction bottle, cool the reaction solution to room temperature, add 500 milliliters of 10% hydrochloric acid aqueous solution, stir for 10 minutes and leave to separate layers; the upper organic layer is washed three times with 500 milliliters of water;

[0052] Place the above organic layer in a reaction flask, add 100 grams of 10% hydrochloric acid aqueous solution, and heat up to 60-80°C for reaction; during the early stage, the azeotrope of methanol, dimethyl carb...

Embodiment 2

[0057] With the feeding amount, reaction temperature and operation sequence of Example 1, change the current value between 500~600 milliamps, the reaction is obviously accelerated, and the reaction can be completed within 2 hours; subsequent reaction and processing are the same as in Example 1, and finally 132 grams of 2-phenylpropionic acid, HPLC purity greater than 99%.

[0058] 1 H NMR (400MHz, CDCl 3 , TMS) δ: 1.54 (d, 3H, J=7.2, CH 3 ),3.77(q,1H,J=7.2,CH),7.32-7.35(m,4H,Ph),11.6-11.8(br s,1H,OH); mass spectrum(70eV)m / z(relativeintensity): 150(M+,29),106(11),105(100),104(5),103(12),79(14),78(6),77(17),51(7).

Embodiment 3

[0060] Put 150 grams of 1-phenylchloroethane and 1050 grams of dimethyl carbonate in the electrolytic cell equipped with magnesium electrodes and carbon electrodes, add 17.5 grams of tetrabutylammonium bromide, control the temperature of the electrolytic cell at 40 °C, and start DC power supply, adjust the current value between 400 ~ 500 milliamps, continue the electrolysis reaction for 3 hours, and the conversion of 1-phenylchloroethane in the HPLC is complete; the follow-up reaction is the same as in Example 1, and finally 152 grams of 2-phenylpropionic acid are obtained , HPLC purity greater than 99%.

[0061] 1 H NMR (400MHz, CDCl 3 , TMS) δ: 1.54 (d, 3H, J=7.2, CH 3 ),3.77(q,1H,J=7.2,CH),7.32-7.35(m,4H,Ph),11.6-11.8(br s,1H,OH); mass spectrum(70eV)m / z(relativeintensity): 150(M+,29),106(11),105(100),104(5),103(12),79(14),78(6),77(17),51(7).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com