Bamboo-wood straw and manufacturing method

A manufacturing method and straw technology, applied in the manufacture of tools, wood processing appliances, etc., can solve the problems of insufficient application prospects of natural bamboo pipes, high difficulty in selection, and large gaps in fiber structures, so as to achieve environmental protection and non-toxicity in the processing process, and reduce material consumption. Cost and quality are stable and controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

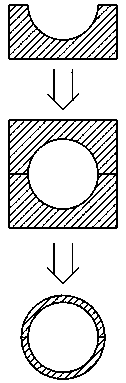

Embodiment 1

[0030] Embodiment 1: The main body of the bamboo straw is a straight tubular structure with uniform wall thickness, and it is characterized in that: the main body of the bamboo straw is fixed by two semi-circular sections to form a complete ring section structure, and Made of bamboo material.

[0031] Further, the inner wall and the outer wall of the bamboo wood straw are smooth surfaces without ridges or burrs.

[0032] Further, one end of the bamboo straw is cut into a flat cut as a drinking port, and the other end is cut into an oblique cut as a piercing hole.

[0033] Further, the wall thickness of the bamboo wood straw is 1.5mm.

[0034] The manufacture method of this bamboo straw comprises the following steps:

[0035] (1) Material selection: Bamboo chooses mature Nanzhu that is more than 6 years old;

[0036] (2) Broken pieces: break the bamboo into bamboo pieces;

[0037] (3) High-temperature cooking: steaming bamboo chips for 8 hours in an environment of 120°C;

...

Embodiment 2

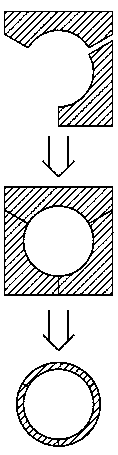

[0048] Embodiment 2: The main body of the wooden straw is a straight tubular structure with uniform wall thickness. become.

[0049] Further, the inner wall and the outer wall of the wooden straw are smooth surfaces without ridges or burrs.

[0050] Further, the wall thickness of the wooden straw is 0.8-1mm.

[0051] The manufacture method of this wooden straw comprises the following steps:

[0052] (1) Material selection: choose nanmu with uniform texture, no holes, and no decay;

[0053] (2) Fragments: cut the wood into strips;

[0054] (3) High-temperature cooking: steam the wooden strips in an environment of 150°C for 12 hours;

[0055] (4) Drying: Dry the wood strips in a constant temperature drying oven, and the moisture content of the dried wood strips will reach 9%;

[0056](5) Prefabrication: Cut the wooden strips into long strips that are radially trisected by the geometric center with a square cross section.

[0057] (6) Inner surface forming: cut the central ...

Embodiment 3

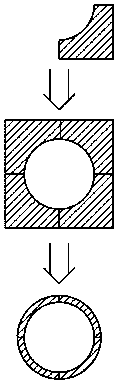

[0064] Embodiment 3: The main body of the bamboo straw is a straight tubular structure with uniform wall thickness. and made.

[0065] Further, the inner wall and the outer wall of the bamboo straw are smooth surfaces without ridges or burrs.

[0066] Further, the wall thickness of the bamboo straw is 2-3mm.

[0067] The manufacture method of this wooden straw comprises the following steps:

[0068] (1) Material selection: Bamboo chooses mature Nanzhu that is more than 8 years old;

[0069] (2) Broken pieces: break the bamboo into bamboo pieces;

[0070] (3) High-temperature cooking: steam the bamboo slices for 12 hours in an environment of 130°C;

[0071] (4) Drying: Dry the bamboo chips in a constant temperature drying oven, and the moisture content of the dried bamboo chips reaches 3%;

[0072] (5) Prefabrication: Cut the bamboo slices into long strips that are radially quartered by the geometric center with a square cross-section.

[0073] (6) Inner surface forming: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com