Wiredrawing solid wood composite floor of special structure and technique thereof

A technology of solid wood composite flooring and special structure, applied in the field of wood flooring, can solve the problems of not meeting the requirements of the lock, unable to withstand the tensile force of the lock, etc., and achieves fast curing speed, good bonding strength, and good bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

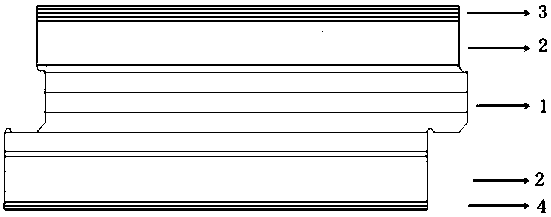

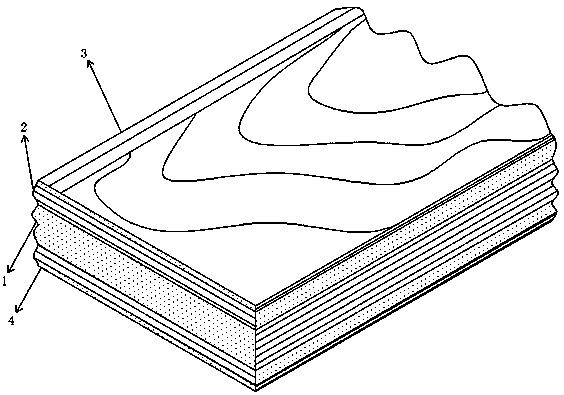

[0041] A brushed solid wood composite floor with a special structure, comprising a core layer 1, a surface layer 3 and a bottom layer 4, a eucalyptus layer 2 is arranged between the core layer 1 and the surface layer 3, and a eucalyptus layer is arranged between the core layer 1 and the bottom layer 4 Layer 2, each layer is formed by criss-cross arrangement of textures and hot-pressed glue-coated blanks. The surface of the surface layer 3 is rough-drawn, with a wire-drawing depth of 0.2-0.4mm; the thickness of the surface layer 3 is 1.2±0.2mm , using hard broad-leaved wood, made of birch; the core layer 1 has a thickness of 8±0.2mm, and adopts pine wood with a moisture content of 6-8%; the thickness of the eucalyptus layer 2 is 3.6±0.2mm; the bottom layer 4 Thickness 0.8±0.2mm, made of beech wood.

Embodiment 2

[0043] A production process of drawing solid wood composite flooring with a special structure, taking the product of 1.2mm birch veneer as an example, including the following processes: the veneer and the base material of corresponding specifications, after gluing, cold pressing, hot pressing, and then enter the balance Room health, after 84 hours, after cutting the material, it will become a plain board (there is no such process for purchased slats). Carry out sanding to ensure that the surface of the board is flat and free of burrs. Then use a wire drawing machine for wire drawing. The wire drawing depth is between (0.2-0.4) mm. Pay attention to the wire drawing effect during operation to avoid the generation of burrs on the board surface.

[0044] After wire drawing, polish the surface of the board. The degree of sanding is relatively light, and the depth is about 0.05mm. The purpose is to ensure that the surface of the board is flat and convenient for subsequent production...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com