Automobile decorative sheet layer structure and layer structure processing technology

A technology for automobile decoration and treatment process, which is applied in the direction of coating, vehicle parts, layered products, etc. It can solve problems such as easy cracking, rust, and unreasonable structure arrangement and treatment, so as to achieve good corrosion resistance and reduce production costs , Improve the output and the effect of qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

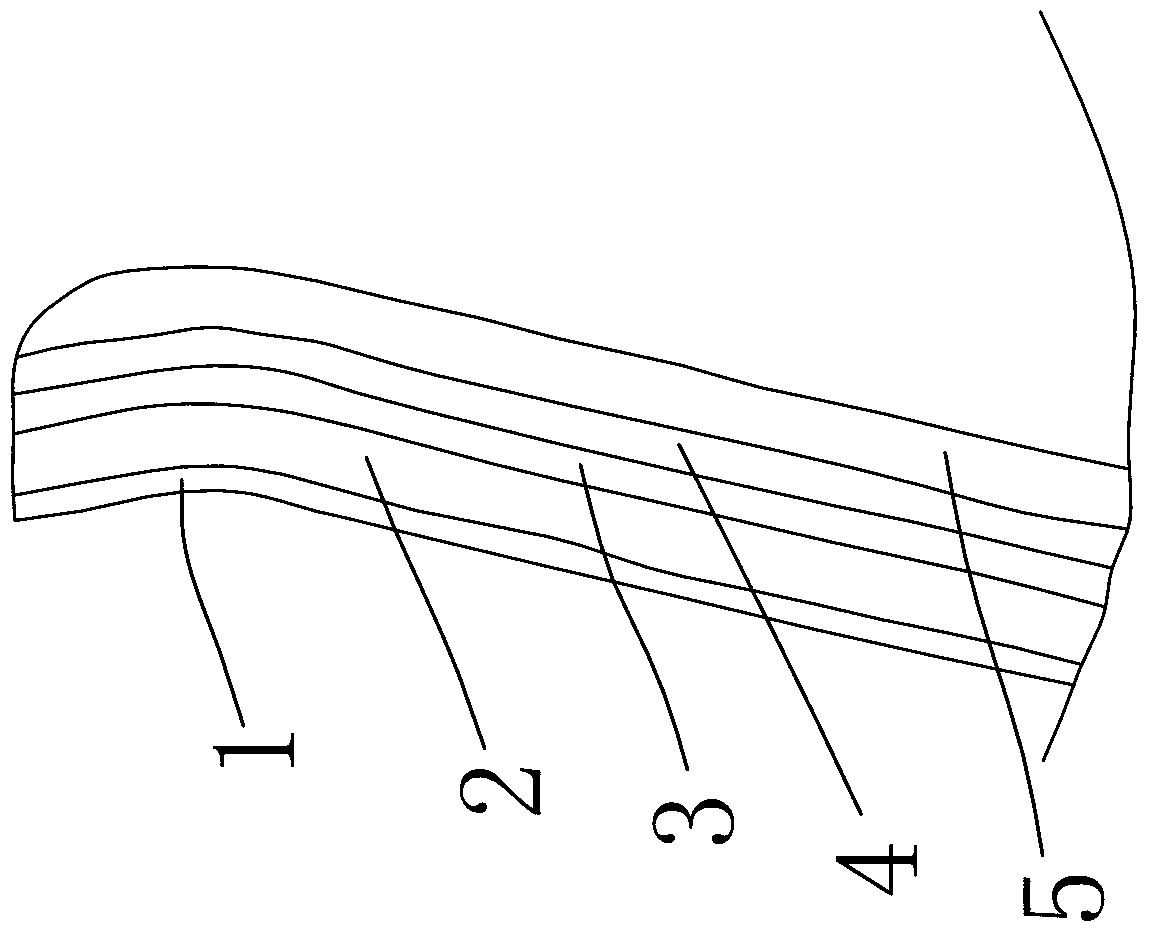

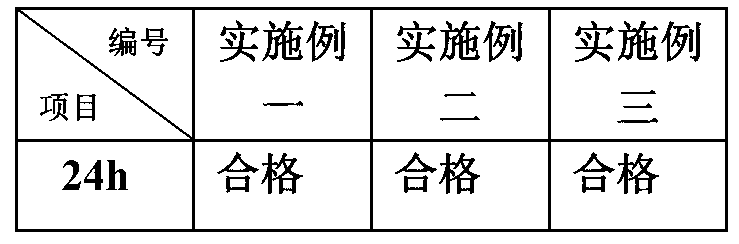

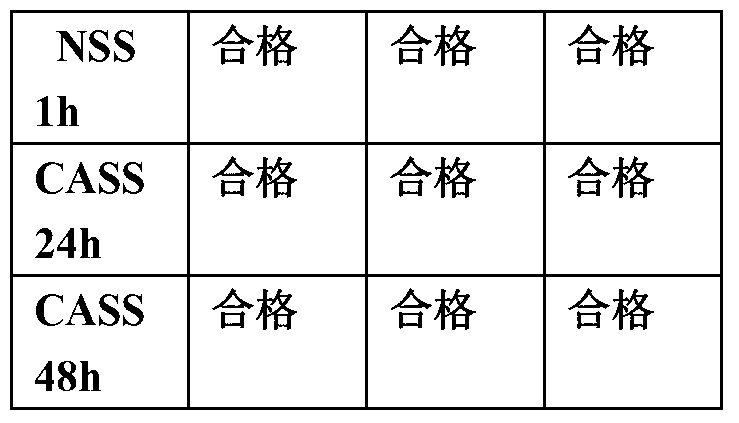

[0019] Such as figure 1 As shown, the structure of the automotive decorative board includes a non-woven fabric layer 1, an aluminum layer 2, a beech wood layer 3, a fiberboard layer 4 and a walnut wood layer 5 from the inside out, and the thickness of the non-woven fabric layer 1 is 0.2 mm. The thickness of aluminum part layer 2 is 0.5mm; The thickness of beech wood layer 3 is 0.3mm; The thickness of fiberboard layer 4 is 0.3mm; Composed of flame retardant formula and waterproof formula, the dry weight ratio of wood fiber, bonding formula, flame retardant formula and waterproof formula is 90:5:4:1, wherein the flame retardant formula includes the following raw materials and weight Specific components: 16 parts of dicyandiamide, 12.0 parts of ammonium dihydrogen phosphate, 5.0 parts of formaldehyde, 10.0 parts of zinc borate, 5.0 parts of ammonia water, 3.0 parts of triethanolamine, 4.0 parts of ethylene propanol, 5 parts of hexamethylenetetramine and 40.0 parts of water, the ...

Embodiment 2

[0021]The difference between the second embodiment and the first embodiment is that the flame retardant formula includes the following raw materials and components by weight: 16.0 parts of dicyandiamide, 24.0 parts of ammonium dihydrogen phosphate, 7.0 parts of formaldehyde, zinc borate 13 parts, 18.0 parts of ammonia water, 3.0 parts of triethanolamine, 4.0 parts of ethylene propanol, 1.0 parts of hexamethylenetetramine and 14 parts of water, spray the mixture of flame retardant formula, adhesive formula and bonding formula after hot grinding After drying, paving, hot pressing, and sanding processes, the fiberboard layer 4 is made on the wood fiber. When the surface of the aluminum layer 2 is electrolytically oxidized first, the wax is removed before the electrolytic oxidation: the aluminum layer 2 Put it into the wax removal solution and treat it for 180 seconds at a temperature of 70°C under the condition of external ultrasonic waves. The concentration of the wax removal sol...

Embodiment 3

[0023] The difference between Example 3 and Example 1 is that the flame retardant formula includes the following raw materials and components by weight: 10.0 parts of dicyandiamide, 10.0 parts of ammonium dihydrogen phosphate, 10 parts of formaldehyde, zinc borate 15 parts, 15 parts of ammonia water, 10 parts of triethanolamine, 10 parts of ethylene propanol, 5 parts of hexamethylenetetramine and 15 parts of water, spray the mixture of flame retardant formula, adhesive formula and bonding formula after hot grinding After drying, paving, hot pressing, and sanding processes, the fiberboard layer 4 is made on the wood fiber. When the surface of the aluminum layer 2 is electrolytically oxidized first, the wax is removed before the electrolytic oxidation: the aluminum layer 2 Put it into the wax removal solution and treat it for 180 seconds at a temperature of 65°C under the condition of external ultrasonic waves. The concentration of the wax removal solution is 150g / l; the wax remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com