Wood plastic clothes rack and manufacturing process thereof

A hanger, wood-plastic technology, applied in the direction of hangers, applications, clothing, etc., can solve the problems affecting the toughness and processing performance of hangers, poor fire resistance and toughness, low plant fiber content, etc., to achieve good market prospects, poor stability, surface Highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

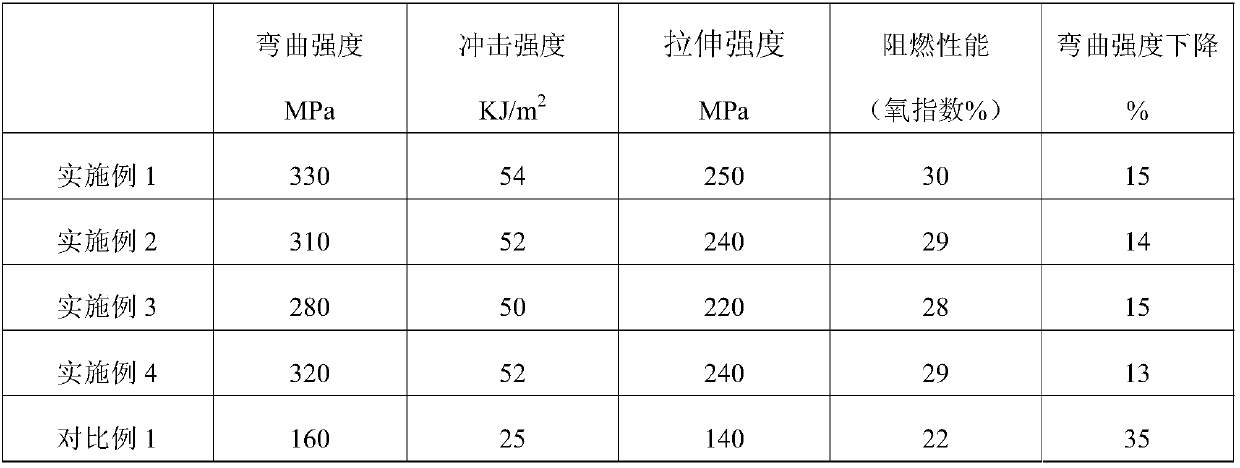

Examples

Embodiment 1

[0032] A wood-plastic clothes hanger comprises the following raw materials in parts by weight:

[0033] 40 parts of beech wood powder, 20 parts of camphor wood powder, 30 parts of waste plastic, 15 parts of modified basalt fiber, 5 parts of glass fiber, 5 parts of magnesium hydroxide, 1 part of heat stabilizer, 1 part of lubricant, 1 part of solubilizer , 4 parts of nano zinc oxide.

[0034] The modified basalt fiber is formed by soaking or coating the basalt fiber with a modifier, and the modifier includes: 40% film-forming agent, 8% coupling agent, 3% lubricant, 10% Modified nano-SiO 2 particles and the rest is water. The film-forming agent is an acrylic resin film-forming agent, the coupling agent is a silane coupling agent, specifically KH560; the lubricant is polyester and carboxylic acid.

[0035] The modified nano-SiO 2 The particles are modified by a silane coupling agent, specifically nano-SiO 2 Particles are dispersed in deionized water, then added with silane c...

Embodiment 2

[0045] A wood-plastic clothes hanger comprises the following raw materials in parts by weight:

[0046] 40 parts of beech wood powder, 20 parts of camphor wood powder, 30 parts of waste plastic, 10 parts of modified basalt fiber, 5 parts of glass fiber, 5 parts of magnesium hydroxide, 1 part of heat stabilizer, 1 part of lubricant, 1 part of solubilizer , 4 parts of nano zinc oxide.

[0047] The modified basalt fiber is formed by soaking or coating the basalt fiber with a modifier, and the modifier includes: 40% film-forming agent, 8% coupling agent, 3% lubricant, 10% Modified nano-SiO 2 particles and the rest is water. The film-forming agent is an acrylic resin film-forming agent, the coupling agent is a silane coupling agent, specifically KH560; the lubricant is polyester and carboxylic acid.

[0048] The modified nano-SiO 2 The particles are modified by a silane coupling agent, specifically nano-SiO 2 Particles are dispersed in deionized water, then added with silane c...

Embodiment 3

[0053] A wood-plastic clothes hanger comprises the following raw materials in parts by weight:

[0054] 40 parts of beech wood powder, 20 parts of camphor wood powder, 5 parts of modified basalt fiber, 5 parts of glass fiber, 5 parts of magnesium hydroxide, 1 part of heat stabilizer, 1 part of lubricant, 1 part of solubilizer, 4 parts of nano zinc oxide share.

[0055] The modified basalt fiber is formed by soaking or coating the basalt fiber with a modifier, and the modifier includes: 40% film-forming agent, 8% coupling agent, 3% lubricant, 10% Modified nano-SiO 2 particles and the rest is water. The film-forming agent is an acrylic resin film-forming agent, the coupling agent is a silane coupling agent, specifically KH560; the lubricant is polyester and carboxylic acid.

[0056] The modified nano-SiO 2 The particles are modified by a silane coupling agent, specifically nano-SiO 2 Particles are dispersed in deionized water, then added with silane coupling agent, stirred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com