Hexatomic-ring alkylsiloxane-phosphate natural gas pipeline corrosion-inhibition drag reducer and preparation method thereof

A six-membered cycloalkylsiloxane and natural gas pipeline technology, which is applied in pipeline systems, chemical instruments and methods, mechanical equipment, etc., can solve the problems of increasing the potential accident rate, reducing the actual application effect, and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

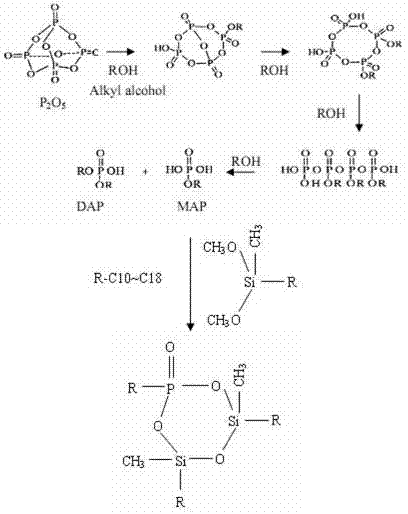

Embodiment 1

[0019] In a 500ml reaction vessel, dissolve dodecyl (C12) alcohol in n-heptane to make a 50% solution; place the 500ml reaction vessel containing the alcohol-heptane solution in a water circulation cooling tank for continuous Slowly add phosphorus pentoxide to the n-heptane solution of alcohol under stirring condition. The molar ratio of alcohol to phosphorus pentoxide is 3:1. During the reaction, the reaction temperature is always kept below 50°C. After 2 hours of reaction, add Water is added dropwise in the reactant, and the mol ratio of water and phosphorus pentoxide is 2:1, continues to react 2 hours back vacuum distillation product is purified, obtains the MAP product based on dodecyl phosphate monoester; Dialkyl (C12) methyldimethoxysilane is dissolved in n-heptane to form a 50wt.% solution, and then the obtained MAP product is added to the solution. Dodecylmethyldimethoxysilane and MAP The molar ratio is 2.5:1, and after stirring and reacting for 3 hours, a six-membered...

Embodiment 2

[0022] In a 500ml reaction vessel, dissolve octadecyl (C18) alcohol in n-heptane to make a 50% solution; place the 500ml reaction vessel containing the alcohol-heptane solution in a water circulation cooling tank for continuous Slowly add phosphorus pentoxide to the n-heptane solution of alcohol under stirring condition. The molar ratio of alcohol to phosphorus pentoxide is 3:1. During the reaction, the reaction temperature is always kept below 50°C. After 2 hours of reaction, add Water is added dropwise in the reactant, and the mol ratio of water and phosphorus pentoxide is 2:1, continues to react 2 hours and then product is purified by underpressure distillation, obtains the MAP product based on octadecyl phosphate monoester; Octadecylmethyldimethoxysilane is dissolved in n-heptane to form a 50wt.% solution, and then the obtained MAP product is added to the solution. The molar ratio of octadecylmethyldimethoxysilane to MAP The ratio is 2.5:1, and after stirring and reacting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com