Deep purification method of feed-grade wet-process phosphoric acid

A wet-process phosphoric acid, deep purification technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of phosphoric acid product quality decline, high energy consumption, solvent loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 10 tons of dilute acid in the aging tank, add wet-process phosphoric acid purification agent inorganic salt I (sodium fluoride, 41kg), inorganic salt II (potassium carbonate, 103kg), inorganic salt III (potassium sulfate, 69kg), inorganic salt IV (calcium bicarbonate, 11kg), the temperature of phosphoric acid is 28°C, the reaction time is 10min, and the stirring rate is 44r / min. After treatment, the removal rates of aluminum phosphate and magnesium in wet process reach 97.19% and 72.68%, respectively. After hot air exchange, the mass ratio of phosphorus to fluorine is 420, P 2 o 5 The recovery rate is 98.9%.

Embodiment 2

[0024] Get 10 tons of dilute acid in the aging tank, add wet-process phosphoric acid deep purification agent inorganic salt I (sodium fluoride, 30kg; magnesium fluoride, 125kg), inorganic salt II (ammonium carbonate, 54kg), inorganic salt III (sulfuric acid Sodium, 77kg), inorganic salt IV (calcium phosphate, 15kg), the temperature of phosphoric acid is 29°C, the reaction time is 15min, and the stirring rate is 106r / min. After treatment, the removal rates of wet-process aluminum phosphate and magnesium reached 97.54% and 71.33%, respectively. After hot air exchange, the fluorine P 2 o 5 / F is 452, P 2 o 5 The recovery rate is 99.1%.

Embodiment 3

[0026] Take 10 tons of dilute acid in the aging tank, add wet-process phosphoric acid deep purification agent inorganic salt I (hydrogen fluoride, 109kg; beryllium fluoride, 1kg), inorganic salt II (potassium carbonate, 33kg; sodium carbonate, 102kg), inorganic salt III (potassium sulfate, 8kg; ammonium sulfate, 56kg; magnesium sulfate, 39kg), inorganic salt IV (calcium dihydrogen phosphate, 21kg), the phosphoric acid temperature is 24°C, the reaction time is 16min, and the stirring rate is 64r / min. After treatment, the removal rates of wet-process aluminum phosphate and magnesium reached 98.14% and 71.33%, respectively. After hot air exchange, the mass ratio of phosphorus to fluorine is 435, P 2 o 5 The recovery rate is 98.8%.

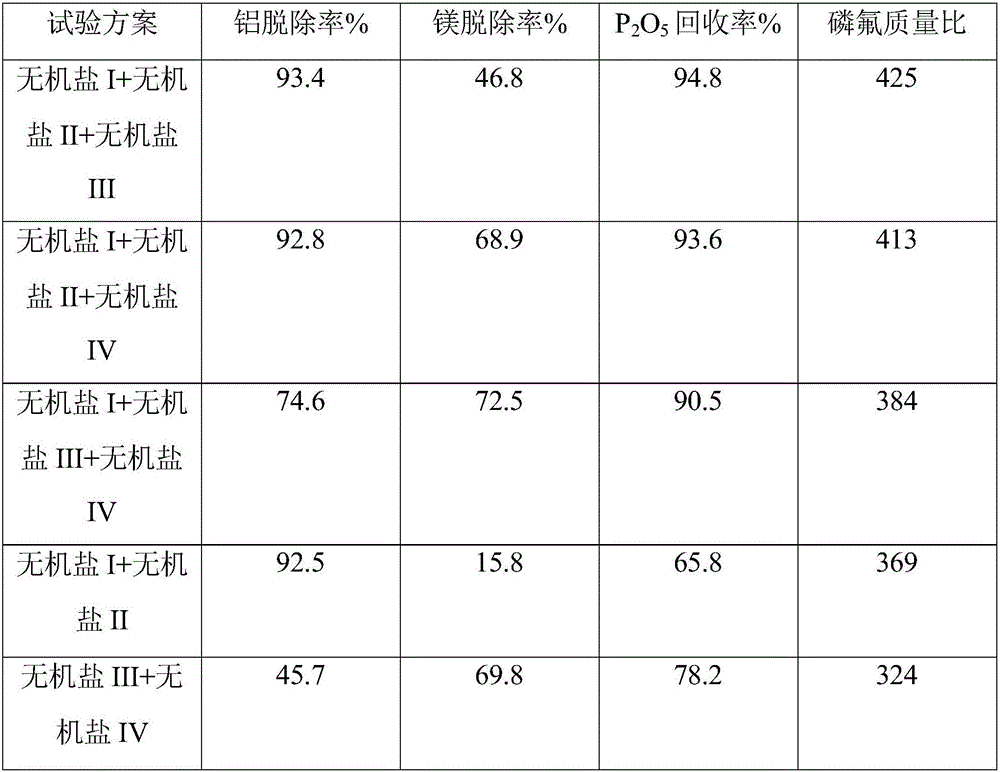

[0027] If the four inorganic salts are reduced to three or two, the test results are shown in Table 1.

[0028]

[0029] As can be seen from Table 1, only the four kinds of salt mixtures provided by the present invention can be used to deeply pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com