Method for preparing battery grade lithium dihydrogen phosphate with high-purity lithium carbonate lithium depositing mother solution

A technology of lithium dihydrogen phosphate and high-purity lithium carbonate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., to achieve good economic and social benefits, low production costs, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

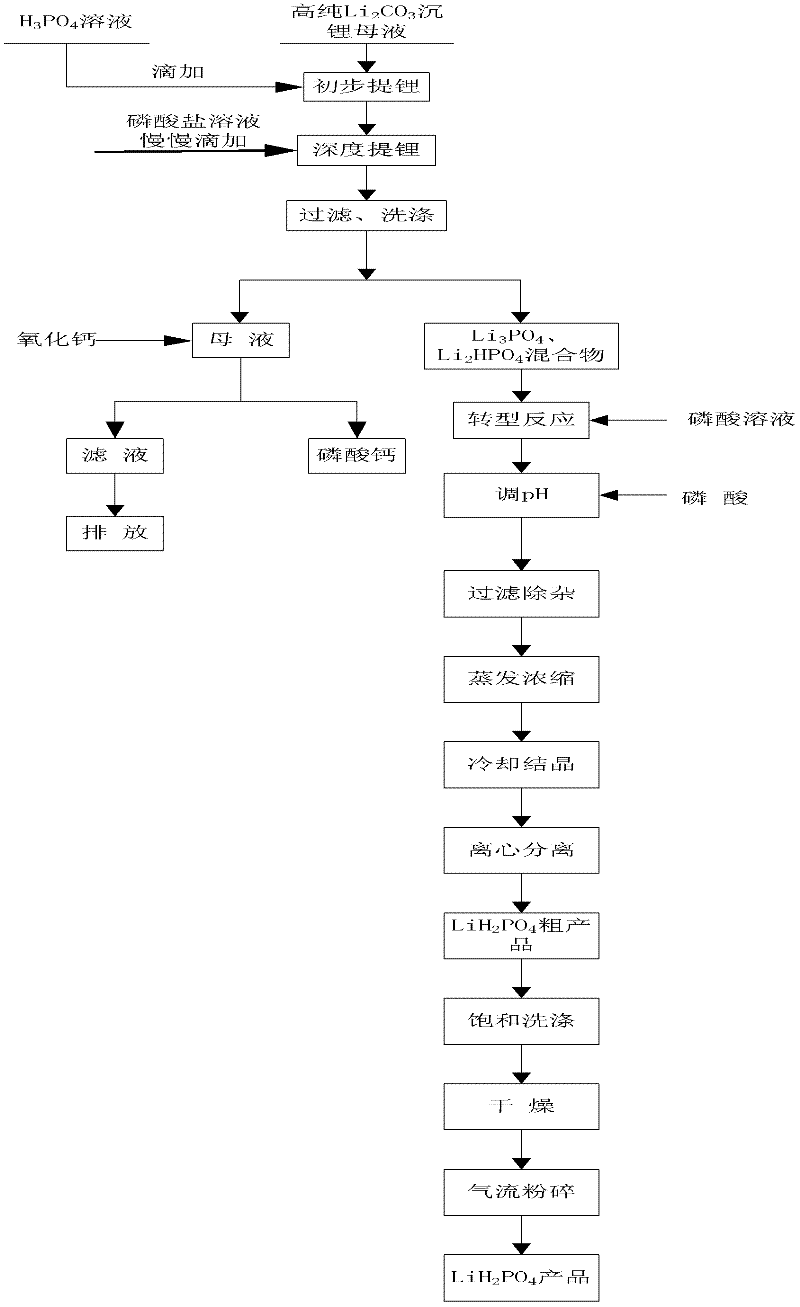

Method used

Image

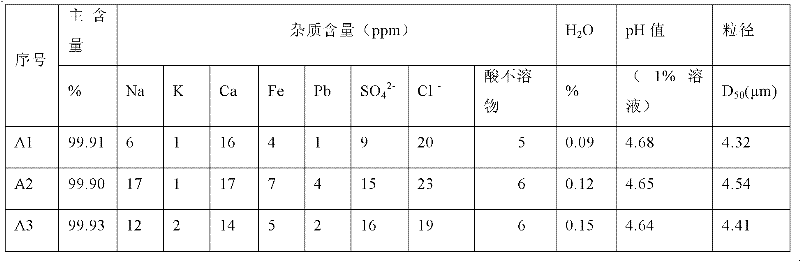

Examples

Embodiment 1

[0052] (a) Add 500L of 99.9% high-purity lithium carbonate mother liquor into the reaction tank, heat it to 90±5℃, start to add 85% phosphoric acid solution dropwise, and control the pH=5 after the reaction to obtain Initial extraction of lithium products;

[0053] (b) After the reaction solution in step (a) is fully stirred, slowly add the disodium hydrogen phosphate solution dropwise, the temperature is controlled at 80 ~ 85 ℃, fully stirred, the end pH value is controlled to pH=7, and kept for 1 hour Then a mixed slurry of lithium phosphate and dilithium hydrogen phosphate is obtained;

[0054] (c) Separate the lithium salt and mother liquor in the mixed slurry of lithium phosphate and dilithium hydrogen phosphate while it is hot, with a lithium extraction rate of 90%;

[0055] (d) Wash the separated mixture of lithium phosphate and dilithium hydrogen phosphate with hot water;

[0056] (e) Add a small amount of purified water to the mixture of lithium phosphate and dilithium hydro...

Embodiment 2

[0062] (a) Add 500L of 99.9% high-purity lithium carbonate mother liquor into the reaction tank, heat it to 90±5℃, start to add 60% phosphoric acid solution dropwise, and control the pH after the reaction to get a preliminary Lithium extraction products;

[0063] (b) After the reaction solution in step (a) is fully stirred, then slowly add the disodium hydrogen phosphate solution dropwise, the temperature is controlled at 80 ~ 85 ℃, fully stirred, the end pH value is controlled to pH = 9, and after 1 hour Obtain a mixed slurry of lithium phosphate and dilithium hydrogen phosphate;

[0064] (c) Separate the lithium salt and mother liquor in the mixed slurry of lithium phosphate and dilithium hydrogen phosphate while it is hot, with a lithium extraction rate of 92%;

[0065] (d) Wash the separated mixture of lithium phosphate and dilithium hydrogen phosphate with hot water;

[0066] (e) Add a small amount of purified water to the mixture of lithium phosphate and dilithium hydrogen phos...

Embodiment 3

[0072] (a) Add 500L of 99.9% high-purity lithium carbonate mother liquor into the reaction tank, heat it to 90±5°C, start dripping 40% phosphoric acid solution, and control the pH=7 after the reaction to obtain Initial extraction of lithium products;

[0073] (b) After the reaction solution in step (a) is fully stirred, slowly add the disodium hydrogen phosphate solution dropwise, the temperature is controlled at 80 ~ 85 ℃, fully stirred, the end pH value is controlled to pH = 10, and after 1 hour Obtain a mixed slurry of lithium phosphate and dilithium hydrogen phosphate;

[0074] (c) Separate the lithium salt and mother liquor in the mixed slurry of lithium phosphate and dilithium hydrogen phosphate while it is hot, with a lithium extraction rate of 91%;

[0075] (d) Wash the separated mixture of lithium phosphate and dilithium hydrogen phosphate with hot water;

[0076] (e) Add a small amount of purified water to the mixture of lithium phosphate and dilithium hydrogen phosphate ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com