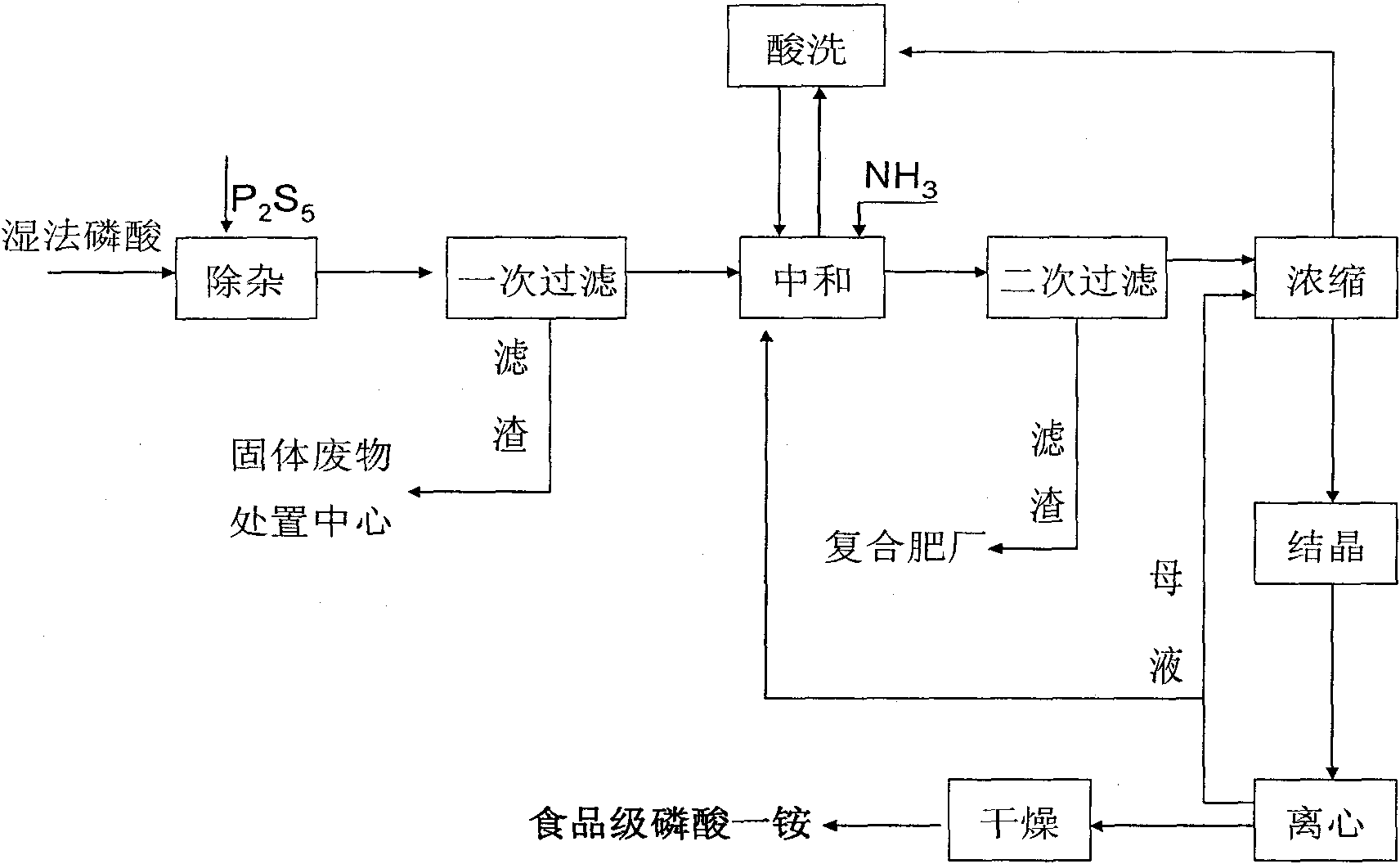

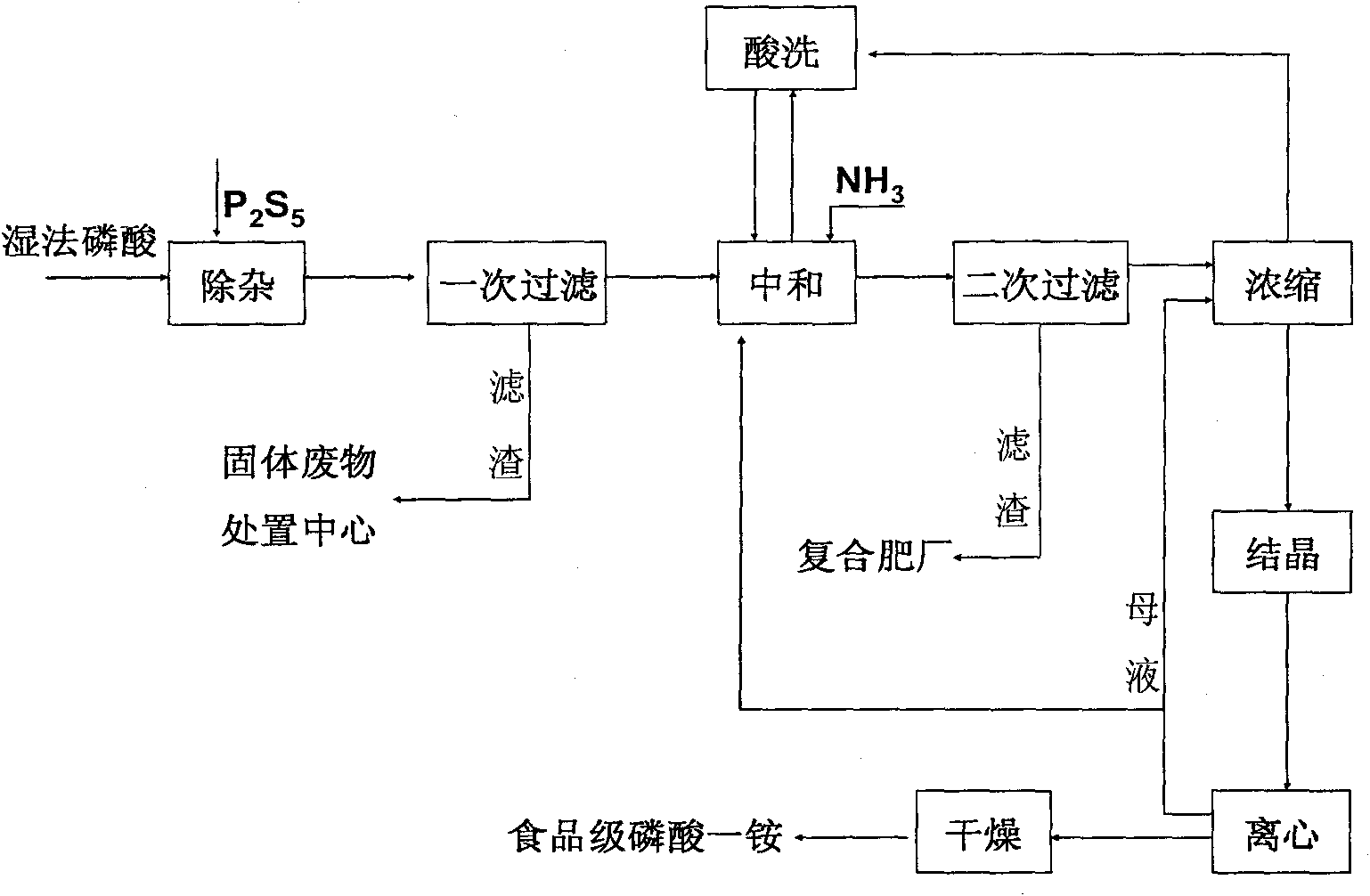

Method for preparing food-grade monoammonium phosphate from wet-process phosphoric acid

A technology of monoammonium phosphate and wet-process phosphoric acid, which is applied in the direction of phosphate, phosphorus oxyacids, applications, etc., can solve the problem of production of food-grade monoammonium phosphate without wet-process phosphoric acid, low production continuity, and unstable product quality To achieve good economic and social benefits, reduce three wastes and energy consumption, and achieve high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add weight concentration 40% P in the raw material pretreatment kettle 2 o 5 Wet-process phosphoric acid, according to the amount of arsenic in it, add 1.1 times the amount of arsenic 2 S 5 , stirred at 60°C for 50 minutes to obtain a sediment-containing slurry; the above-mentioned slurry was filtered for the first time with a plate and frame filter press while it was hot, the filtrate was used for neutralization, and the filter cake was sent to the solid waste disposal center; Put the recovered crystallization mother liquor with 18% of the volume of the reaction kettle into the enamel reaction kettle, start the agitator, slowly add the impurity-removed phosphoric acid, and slowly pass in ammonia gas, control the pH=4.4 and carry out the neutralization reaction at a temperature of 55°C, and the volatilized ammonia After being absorbed by the pickling bubbling absorption tower, the gas is refluxed into the reaction kettle, and the pH=4.4 is controlled as the end point ...

Embodiment 2

[0035] Put into the weight concentration 38% P in the raw material pretreatment kettle 2 o 5 Wet-process phosphoric acid, add 1.3 times the amount of arsenic according to the arsenic content of P 2 S 5 , stirred at 50°C for 60 minutes to obtain a sediment-containing slurry; use a plate and frame filter press to filter the above slurry for the first time while it is hot, the filtrate is used for neutralization, and the filter cake is sent to the solid waste disposal center; Put the recovered crystallization mother liquor with 15% of the volume of the reaction kettle into the stainless steel reaction kettle, start the agitator, slowly add the impurity-removed phosphoric acid, and slowly pass in ammonia gas, control the pH=4.6 and carry out the neutralization reaction at a temperature of 70°C, and the volatilized ammonia After the gas is absorbed by the pickling packing absorption tower, it is refluxed into the reaction kettle, and the pH=4.6 is controlled as the end point of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com