Equipment for producing high-nutrient monoammonium phosphate through double-tubular-reactor process

A technology of monoammonium phosphate and double-pipe reaction, applied in the field of ammonium phosphate, to achieve the effect of overcoming hysteresis, stable and good equipment operation status, and perfect functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

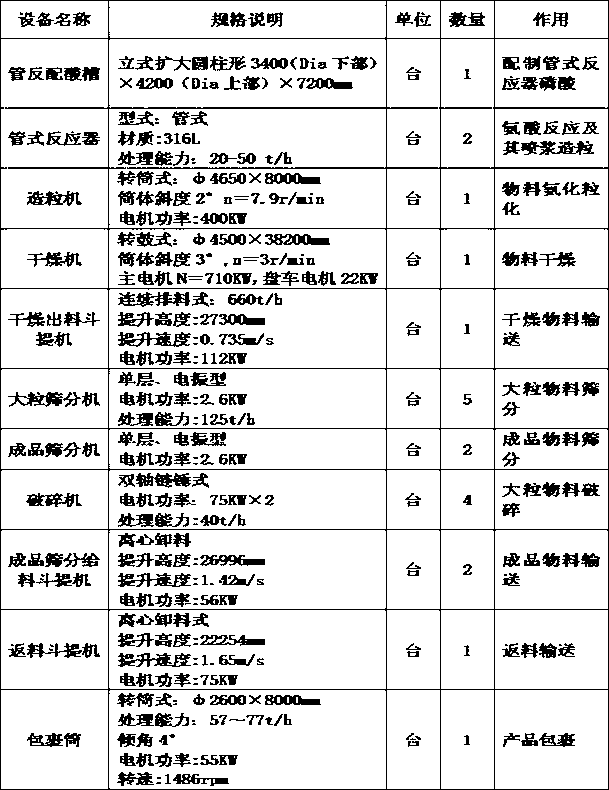

[0040] An equipment for producing high-nutrient monoammonium phosphate using a double-pipe reverse process, including a concentrated phosphoric acid clarification tank 1, a pipe reverse acid tank 2, a granulator 3, tubular reactors 5 and 6, a dryer 4, and a bucket elevator , Screening machine 8, crusher 9, belt conveyor, cooling fluidized bed 14, wrapping cylinder 17, cyclone separator, dust removal fan, exhaust gas washing system;

[0041] Described tubular reactor comprises tubular reactor A5 and tubular reactor B6, and the mixing head 18 of two tubular reactors is installed in the afterbody of granulator 3, and the input pipeline of pipe anti-match acid tank 2 and liquid ammonia The input pipeline of the storage tank 19 is cut in vertical direction at the mixing head place of each tubular reactor respectively;

[0042] The granulator 3 is a rotary drum ammoniation granulator; it is supported by a central girder on which an ammoniation granulation device is installed. Exten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com