Novel detection method for self-discharge characteristics of lithium iron phosphate system power lithium ion batteries

A lithium-ion battery, lithium iron phosphate technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems affecting the accuracy of data acquisition, the deviation of capacity acquisition conditions, etc., to aggravate the trend of self-discharge changes and improve the accuracy of The effect of increasing the stability and reliability, chemical reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

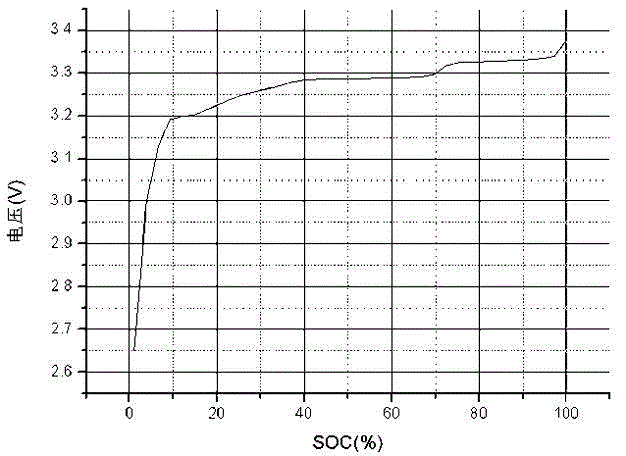

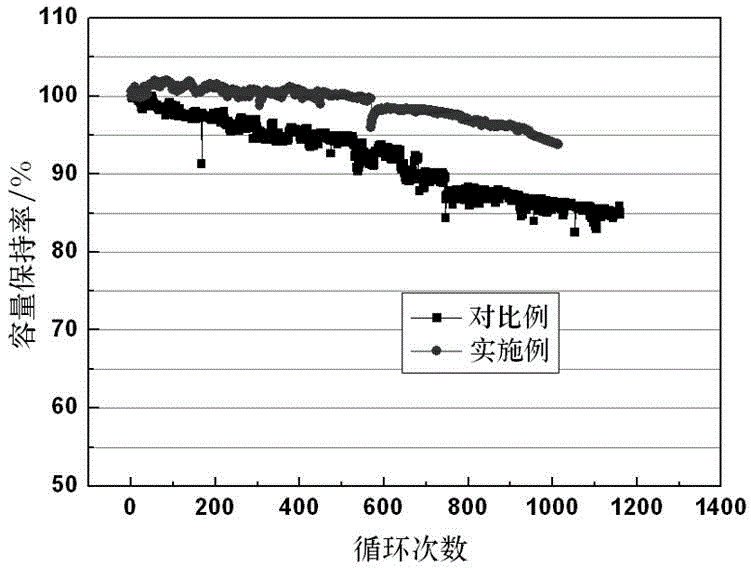

[0042] Perform self-discharge detection processing on the lithium iron phosphate power lithium-ion battery after capacity separation: Step 1, SOC state adjustment: use 0.5C current to charge and discharge the battery twice, and then use 0.5C, 0.2C , 0.1C, 0.05C different currents are divided into 4 steps of constant current discharge, adjust the SOC state of the battery to 0%, then charge with a current of 0.5C for 0.8h, and then discharge with a current of 0.5C for 0.1 hour, adjust the SOC state of the battery to 35%; step 2, the first voltage measurement: the battery is left to stand for 24 hours, and the battery voltage OCV1 is detected after the battery voltage is stable; step 3, high temperature aging: the battery is clamped with a special clamp and placed in a high temperature aging room. At 40±3°C, aging for 20 days; step 4, the second voltage measurement: take the battery out of the high-temperature aging room, place it at room temperature for no less than 8±2h, and che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com