Method for manufacturing solar cell

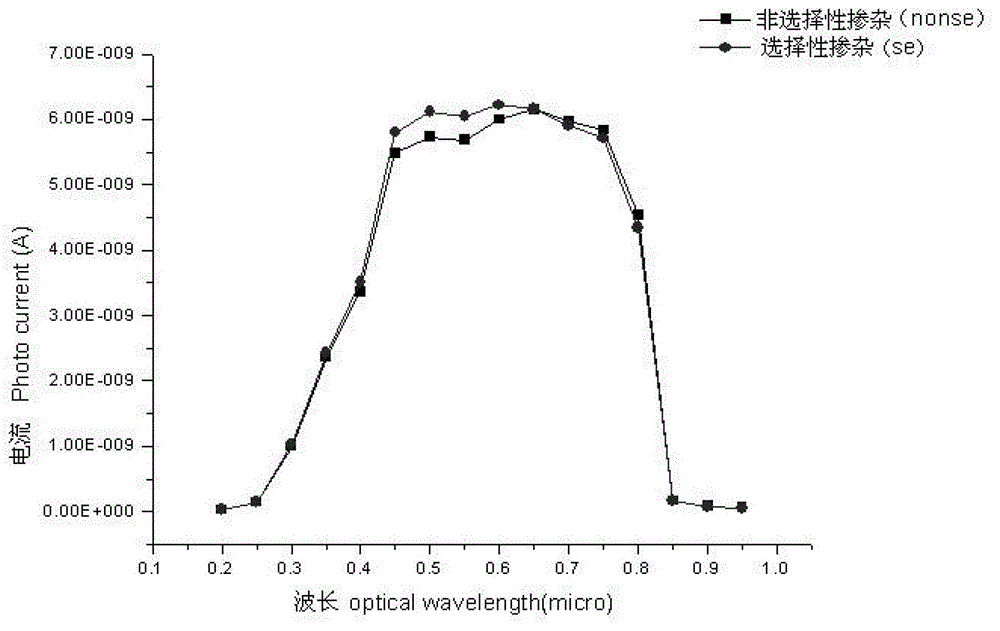

A solar cell and manufacturing method technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of inability to identify the electrode window with the naked eye, defective rate, increased production cost, and complicated process, and achieve low cost , Simple and cost-effective, the effect of increasing the doping concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

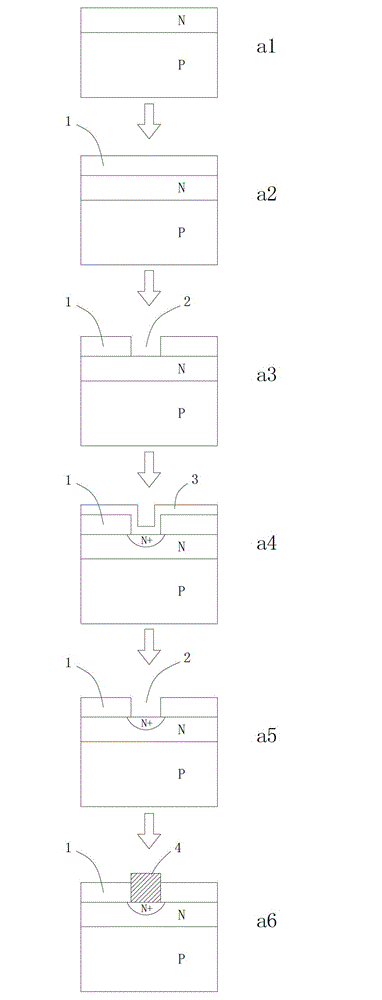

[0025] The purpose and effects of the present invention will become more apparent by referring to the accompanying drawings in detail of the present invention.

[0026] Such as figure 1 As shown, the solar cell manufacturing method of this embodiment includes the following steps:

[0027] a1. Pre-doping the P-type silicon wafer substrate with a resistivity of 3Ω m after texturing to form a P-N junction; the pre-doping concentration is 10 16 / cm 3 , the pre-doping time is 60min, and the pre-doping temperature is 900°C.

[0028] a2. A layer of silicon nitride layer 1 is deposited on the surface of the silicon wafer. The silicon nitride layer 1 is used as a masking layer for selective doping and also as an anti-reflection layer of the solar cell.

[0029] a3. Open the electrode window 2 on the surface of the silicon wafer by laser etching.

[0030] a4. Use phosphorus-doped silicon dioxide to perform secondary deposition on the surface of the silicon wafer, and at the same tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com