Reactive conductive pressure-sensitive adhesive tape

A conductive tape, reactive technology, used in conductive adhesives, circuits, adhesives, etc., can solve problems such as inability to provide processing strength, and achieve the effect of improving electrical reliability and reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

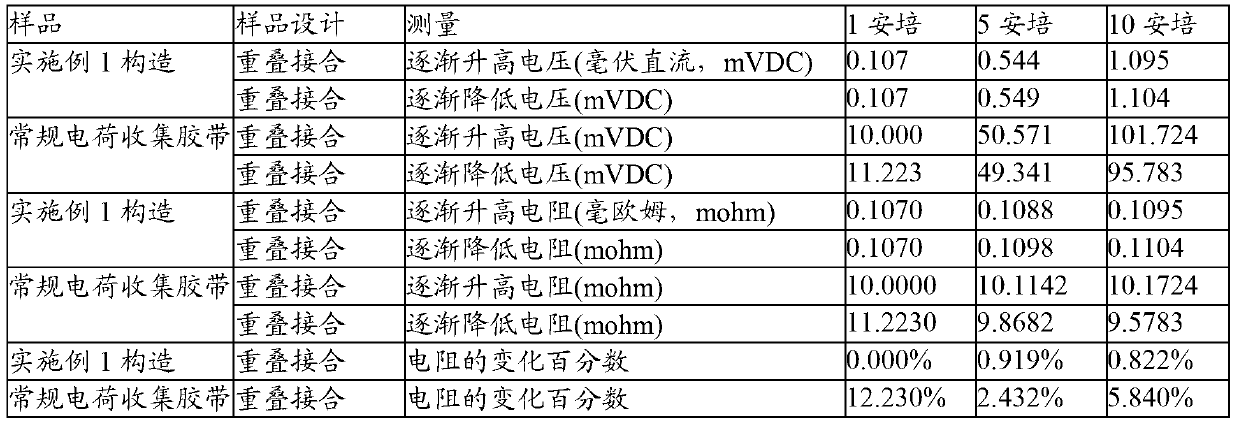

[0041] Example 1 illustrates an embodiment of a reactive conductive PSA based on a curable acrylic base polymer and a free radical curable crosslinking component. The pressure sensitive adhesive composition was formulated as described in Table 1, where parts are by weight.

[0042] Table 1

[0043] project description

Quantity (ppH)

Epoxy, carboxylic acid functional acrylic polymer

41.0

Hydrophobic aliphatic urethane acrylate oligomer

3.7

10.3

0.1

Silver-coated nickel particles

21.9

23.0

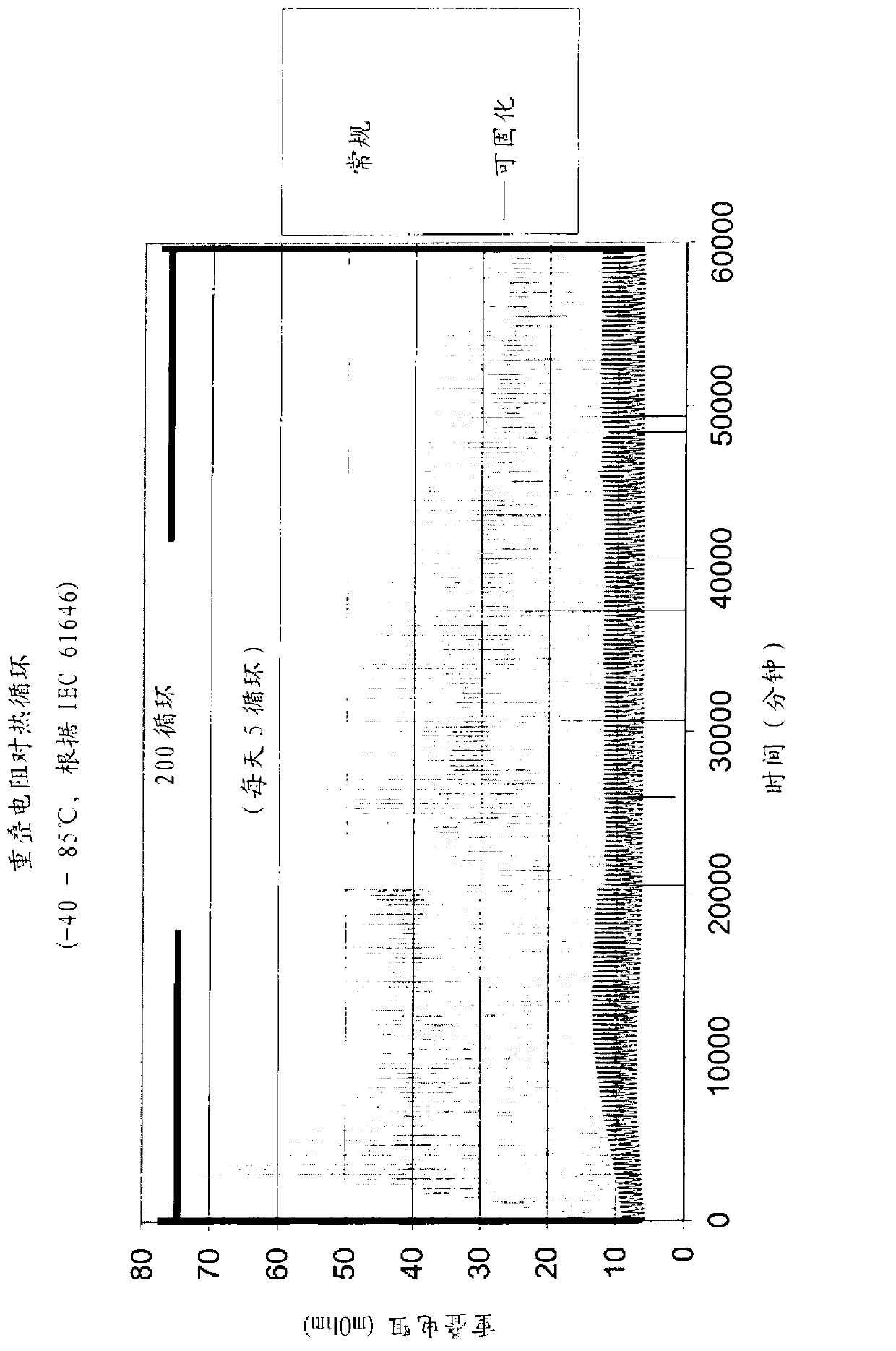

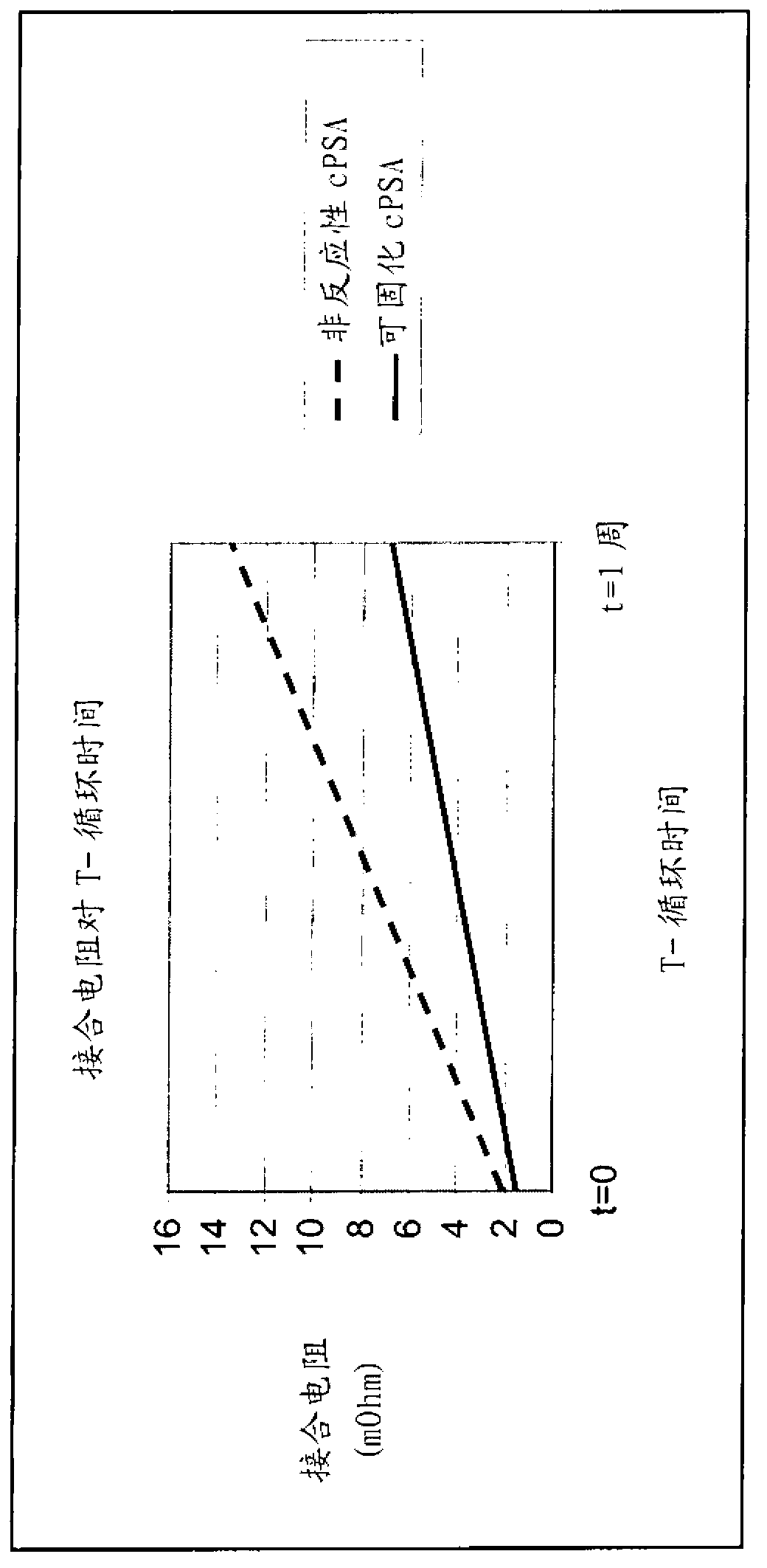

[0044] The glass transition temperature (T g ) at -23°C in the uncured state, T in the cured state g is -24°C, which is favorable for reliable performance during thermal cycling that occurs in photovoltaic cells used under harsh conditions. low T g The flexible adhesive deforms and compensates for stresses developed during thermal cycling and ...

Embodiment 2

[0059]Example 2 illustrates a reactive conductive PSA formed from a hydroxyl functional acrylic PSA polymer base resin and a blocked isocyanate crosslinking component. A solvent-borne conductive PSA was formed by combining a hydroxyl-functional acrylic polymer (27 g, 90 parts by weight ethylhexyl acrylate, 10 parts by weight hydroxyethyl acrylate, Mn ~ 250K, Mw ~ 550K) and blocked isocyanate Solution Trixene BI-7982 (4 g, DMP-terminated HDI trimer from Baxenden Chemical) was dissolved in ethyl acetate (70 g). To this solution, nominally 35 μm Ag-coated glass beads (15 g, Conduct-O-Fil TP35-S12 from Potters Industries) were added slowly and stirred using a mechanical paddle mixer.

[0060] This solution was coated on a 2 mil PET release liner using a bar drawdown coater and dried at 65°C for 5 minutes to form a film about 38 μm thick, giving a tacky, Uncured PSA film.

[0061] This film was laminated to a 36 micron tin-coated copper foil substrate using a lamination pressure ...

Embodiment 3

[0063] Like Example 2, Example 3 is another example of a reactive conductive PSA formed from a hydroxyl functional acrylic PSA polymer base resin and a blocked isocyanate crosslinking component. A curable conductive PSA similar to that described in Example 2 was formulated by combining a hydroxy-functional acrylic PSA base resin (8.9 g polymer in 13.4 g ethyl acetate solvent), Dimethylpyrazole (DMP)-hexamethylene diisocyanate (HDI) trimer adduct blocked isocyanate curing agent (1.1 g adduct in 1.1 g methyl ethyl ketone solvent), and Ag Coated glass beads (2.1 g) and stirred using a vortex mixer. This adhesive was coated onto a release liner using a drawdown bar and dried in a convection oven to give a 1.7 mil thick dried adhesive film. This film was laminated to a Sn-coated Cu foil backing using a lab roll.

[0064] One inch wide strips of this laminate were cut, the release liner was removed, and the strips were laminated to stainless steel test panels according to PSTC met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com