Method for recovering waste lithium iron phosphate battery positive pieces

A technology of lithium iron phosphate battery and recycling method, which is applied in the direction of battery recycling, waste collector recycling, recycling technology, etc., to achieve the effect of reducing environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

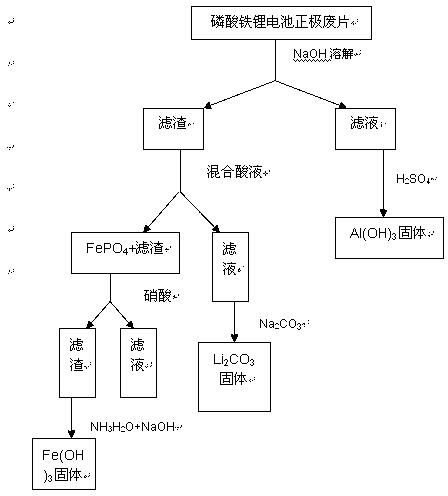

Image

Examples

Embodiment 1

[0026] Disassemble the lithium iron phosphate battery, take out the positive electrode, weigh 11.8564 grams, heat at 200°C for 4 hours, put the pretreated positive electrode waste in a beaker, add 250ml of NaOH to soak, and dissolve the positive aluminum foil completely within 4 hours. And the separation from the surface coating layer; after filtering the above, add a certain amount of acid in the filtrate to leach Al, and use Al(OH) 3 Precipitated in the form; the solid residue of the filter was dissolved in the mixed acid solution of sulfuric acid + hydrochloric acid, iron existed in the solid in the form of ferric phosphate, and lithium entered the solution as an ion component, stirred at 50°C for 12 hours; filtered, the filtrate contained lithium ions, Add saturated sodium carbonate at 95°C, lithium is precipitated as lithium carbonate solid, and hydrochloric acid is added to the filter residue, and iron enters the solution in the form of ions to realize separation from sol...

Embodiment 2

[0028] Disassemble the lithium iron phosphate lithium battery, take out the positive electrode, weigh 12.3321 grams, heat at 300°C for 3 hours, put the pretreated positive electrode waste in a beaker, add 250ml of NaOH to soak, and the positive aluminum foil is completely dissolved in 4 hours , and separate from the surface coating layer; after filtering the above, add a certain amount of acid to the filtrate to leach Al, and use Al(OH) 3 Precipitated in the form; the solid residue of the filter was dissolved in the mixed solution of sulfuric acid + bromic acid, iron existed in the solid in the form of ferric phosphate, and lithium entered the solution as an ion component, stirred at 50°C for 12 hours; filtered, the filtrate contained lithium ions, Add saturated sodium carbonate at 95°C, lithium is precipitated as solid lithium carbonate, nitric acid is added to the filter residue, iron enters the solution in the form of ions, and is separated from solid impurities, stirred at ...

Embodiment 3

[0030] Disassemble the lithium iron phosphate battery, take out the positive electrode, weigh 11.2381 grams, heat in a high-temperature furnace at 350°C for 2.5 hours, put the pretreated positive electrode waste in a beaker, add 250ml of NaOH to soak, and leave the positive electrode aluminum foil for 4 hours Completely dissolve and separate from the surface coating layer; after filtering the above, add a certain amount of acid to the filtrate to leach Al, and use Al(OH) 3 Precipitated in the form; the solid residue of the filter was dissolved in the mixed acid solution of hydrochloric acid + hydrogen peroxide, iron existed in the solid in the form of ferric phosphate, and lithium entered the solution as an ion component, stirred at 50°C for 12 hours; filtered, the filtrate contained lithium ions, add saturated sodium carbonate at 95°C, lithium is precipitated as lithium carbonate solid, nitric acid is added to the filter residue, iron enters the solution in the form of ions, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com