Lithium transition-metal oxide cell

A technology of lithium transition metals and oxides, applied in battery electrodes, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of poor cycle life, low charge and discharge performance, low initial efficiency, etc., and achieve improved adhesion Focus on improving power performance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

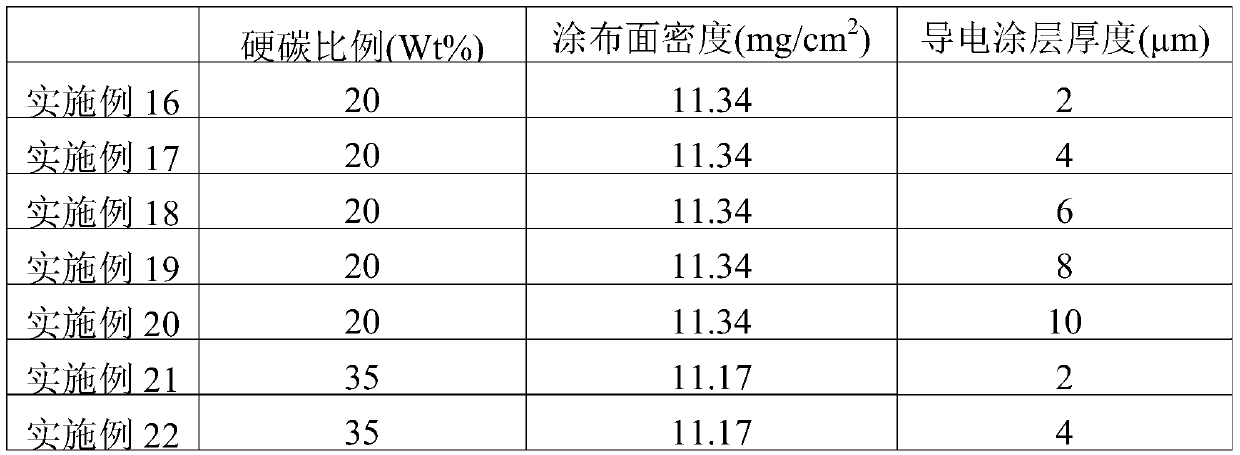

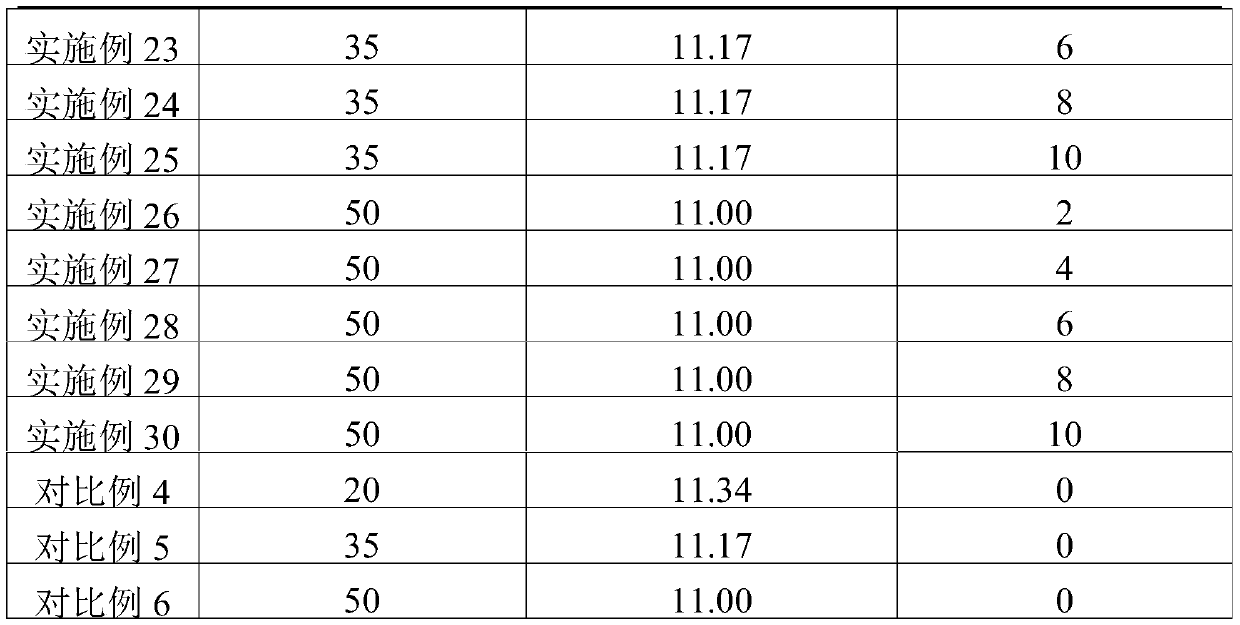

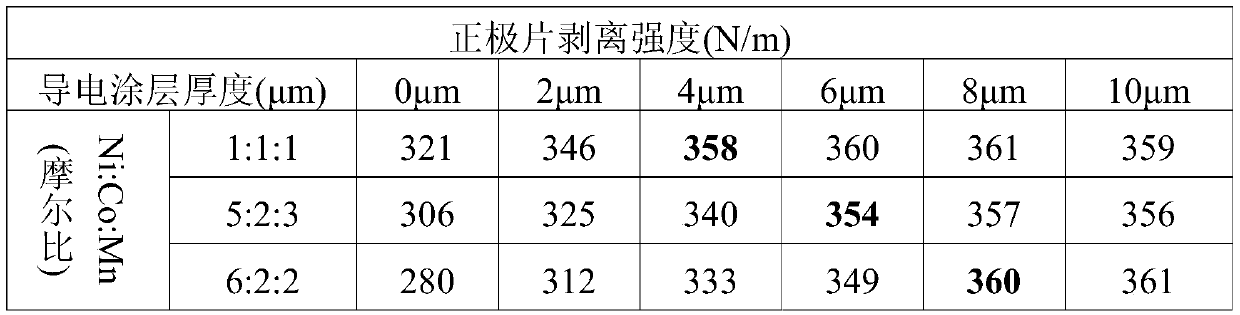

Examples

Embodiment 1

[0028] A lithium transition metal oxide battery, comprising a negative electrode sheet and a positive electrode sheet;

[0029] The negative electrode sheet includes a negative electrode active material layer, a negative electrode collector Cu foil, and the negative electrode active material layer includes a mixture of graphite and hard carbon, a negative electrode binder, and a negative electrode conductive agent. The negative electrode active material layer adopts graphite (95wt%), and the negative electrode The conductive agent uses SuperP (2wt%), and the negative electrode binder uses CMC (1wt%) and SBR (2wt%);

[0030] The positive electrode sheet includes a positive electrode active material layer, a positive electrode current collector Al foil, and a positive electrode conductive coating. The positive electrode active material layer includes a lithium transition metal oxide, a positive electrode binder, and a positive electrode conductive agent. The lithium transition me...

Embodiment 2

[0043] A lithium transition metal oxide battery, comprising a negative electrode sheet and a positive electrode sheet;

[0044] The negative electrode sheet includes a negative electrode active material layer, a negative electrode collector Cu foil, and the negative electrode active material layer includes a mixture of graphite and hard carbon, a negative electrode binder, and a negative electrode conductive agent. The negative electrode active material layer adopts graphite (95wt%), and the negative electrode The conductive agent uses SuperP (2wt%), and the negative electrode binder uses CMC (1wt%) and SBR (2wt%);

[0045] The positive electrode sheet includes a positive electrode active material layer, a positive electrode current collector Al foil, and a positive electrode conductive coating. The positive electrode active material layer includes a lithium transition metal oxide, a positive electrode binder, and a positive electrode conductive agent. The lithium transition me...

Embodiment 3

[0048] A lithium transition metal oxide battery, comprising a negative electrode sheet and a positive electrode sheet;

[0049] The negative electrode sheet includes a negative electrode active material layer, a negative electrode collector Cu foil, and the negative electrode active material layer includes a mixture of graphite and hard carbon, a negative electrode binder, and a negative electrode conductive agent. The negative electrode active material layer adopts graphite (95wt%), and the negative electrode The conductive agent uses SuperP (2wt%), and the negative electrode binder uses CMC (1wt%) and SBR (2wt%);

[0050] The positive electrode sheet includes a positive electrode active material layer, a positive electrode current collector Al foil, and a positive electrode conductive coating. The positive electrode active material layer includes a lithium transition metal oxide, a positive electrode binder, and a positive electrode conductive agent. The lithium transition me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com