Lithium ion battery as well as preparation method thereof and lithium-ion battery pack

A lithium-ion battery pack, lithium-ion battery technology, applied in battery pack components, secondary batteries, secondary battery repair/maintenance, etc., can solve the problem that the rate performance cannot be fully utilized, the heat dissipation efficiency is low, and the battery charging time is reduced. and other problems, to achieve the effect of improving high-rate charge and discharge performance, improving heat dissipation efficiency, and optimizing current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

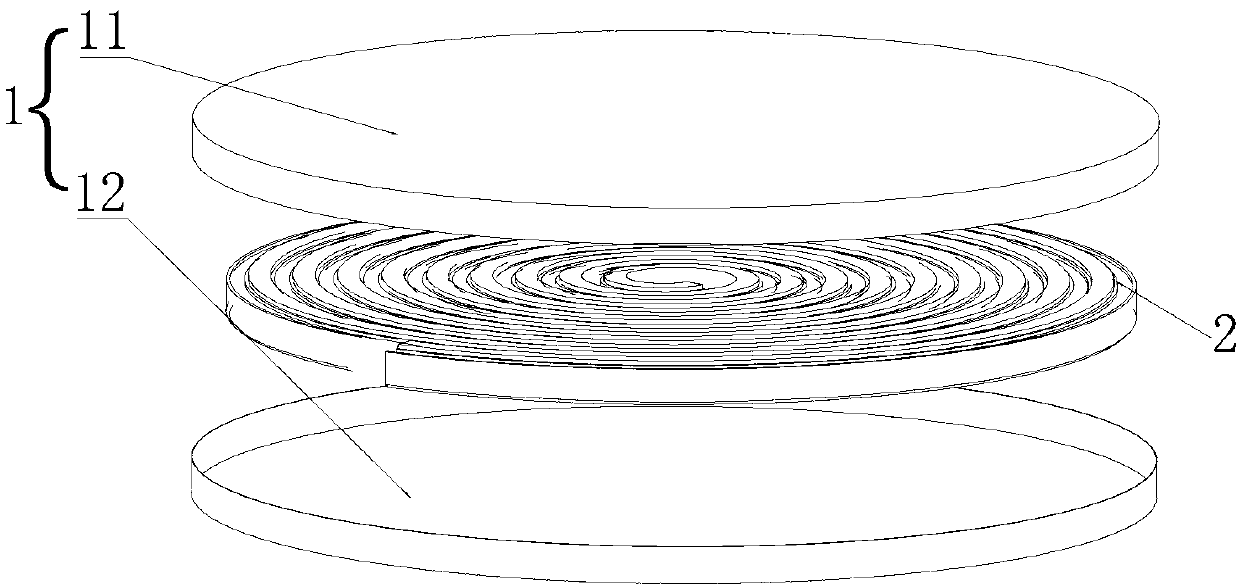

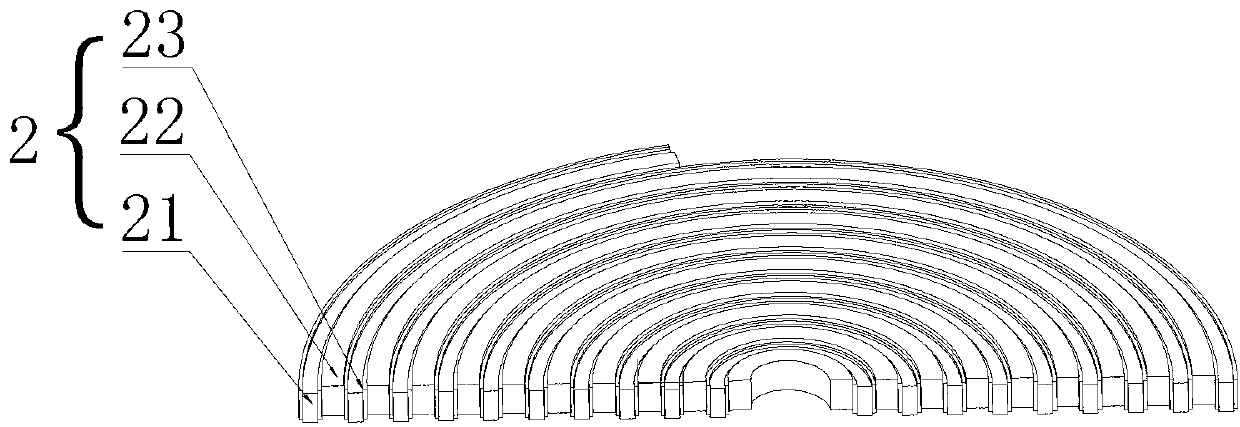

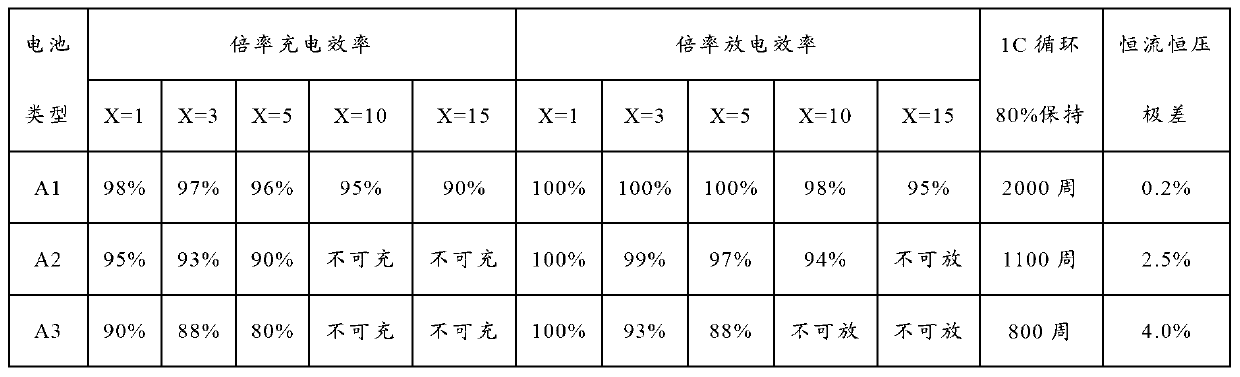

[0059] The positive plate is made of nickel-cobalt lithium manganate, the negative plate is made of natural graphite, and the separator is a lithium-ion battery separator with a thickness of 20um. The positive and negative plates are separated by the diaphragm by winding. Open, the two ends of the positive and negative electrodes are respectively reserved for the positive and negative end faces beyond the diaphragm, the positive electrode plate on the positive end face is 1mm beyond the diaphragm, the negative electrode plate on the negative end face is 1mm beyond the diaphragm, and the diaphragm exceeds the lower edge of the positive and negative electrodes by 1mm, so as to prepare a height of 14mm , A pole group with a diameter of 64mm, the pole group is packaged in a metal shell with a diameter of 66mm and a height of 16mm to prepare a lithium-ion battery with a capacity of 5Ah. The lithium-ion battery prepared by this preparation process is regarded as lithium-ion battery A1...

Embodiment 2

[0082] According to the lithium-ion battery preparation method provided by the present invention, the positive plate is made of traditional nickel-cobalt lithium manganate, the negative plate is made of traditional natural graphite, and the separator is a lithium-ion battery separator with a thickness of 20um. The positive and negative plates are separated by the diaphragm, and the positive and negative end faces of the positive and negative electrodes are respectively reserved beyond the diaphragm. The bottom edge of the pole is 1mm, and a pole group with a height of 24mm and a diameter of 64mm is prepared. The pole group is packaged in a metal shell with a diameter of 66mm and a height of 26mm to prepare a lithium-ion battery with a capacity of 10Ah. The battery prepared by this preparation process is counted as Battery A4.

[0083] The battery rate charge and discharge, cycle life, process consistency and safety evaluation methods are the same as those in Example 1.

Embodiment 3

[0085] According to the lithium-ion battery preparation method provided by the present invention, the positive plate is made of traditional nickel-cobalt lithium manganate, the negative plate is made of traditional natural graphite, and the separator is a lithium-ion battery separator with a thickness of 20um. The positive and negative plates are separated by the diaphragm, and the positive and negative end faces of the positive and negative electrodes are respectively reserved beyond the diaphragm. The bottom edge of the pole is 1mm, and a pole group with a height of 34mm and a diameter of 64mm is prepared. The pole group is packaged in a metal shell with a diameter of 66mm and a height of 36mm to prepare a lithium-ion battery with a capacity of 15Ah. The battery prepared by this preparation process is counted as Battery A5.

[0086] The battery rate charge and discharge, cycle life, process consistency and safety evaluation methods are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com