Method for preparing surface self-grown titanium nitride conducting film modified lithium titanate

A technology of lithium titanate and titanium nitride, used in circuits, electrical components, battery electrodes, etc., can solve problems such as poor electronic conductivity, achieve firm and tight contact, improve electronic conductivity, and improve high-rate charge-discharge performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] According to urea: Li 4 Ti 5 o 12 1.23 g of urea was added at a mass ratio of 5%, ball milled and mixed in absolute ethanol medium for 2 h, and then put into a vacuum drying oven at 70° C. for 8 h. After drying in an atmosphere furnace in N 2 Under a protective atmosphere, the temperature was raised to 800°C at a rate of 2°C / min for 30 minutes, and then cooled with the furnace. The resulting product is Li 4 Ti 5 o 12 / TiN composite electrode material.

[0026] Material performance characterization:

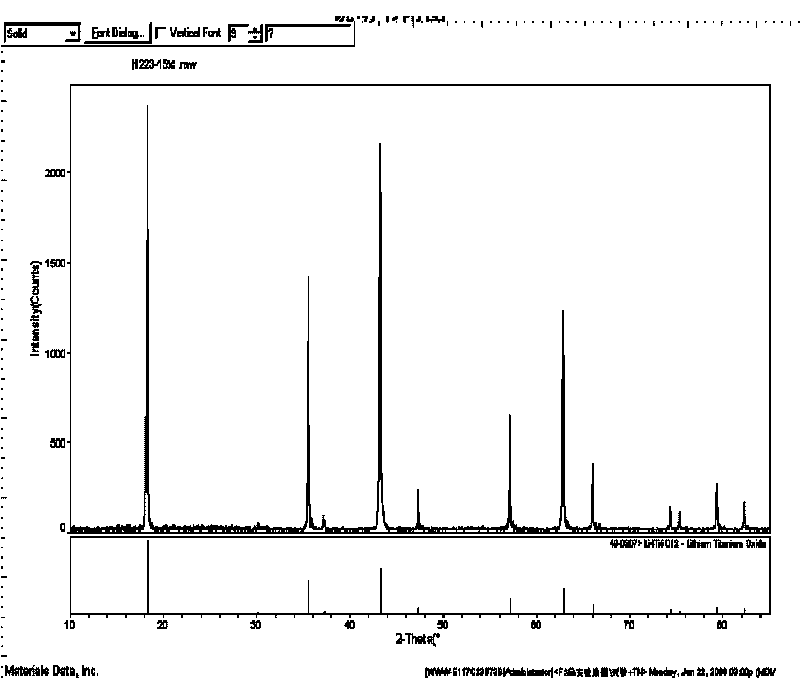

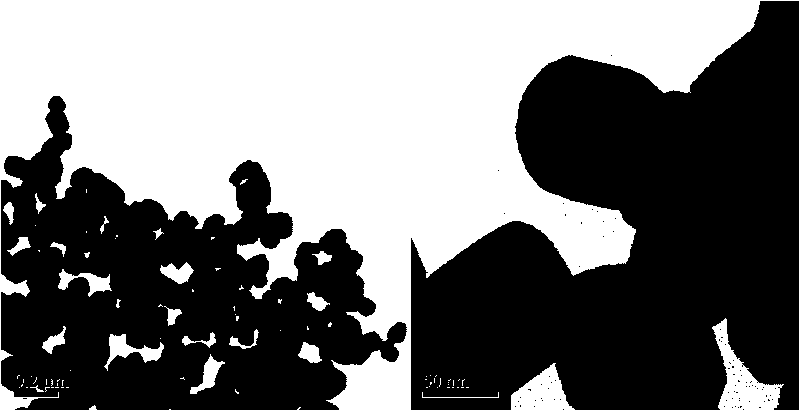

[0027] The crystal structure of the material was analyzed with a Rigaku 3014 X-ray diffractometer in Japan, and the morphology of the material was observed with a transmission electron microscope TEM (PhilipsCM12).

[0028] Electrochemical performance test:

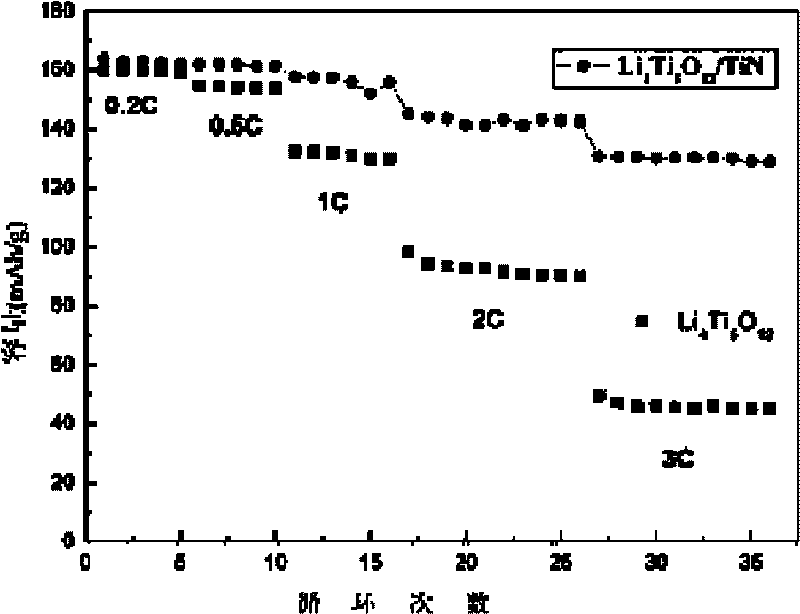

[0029] Both the electrode sheet and the lithium half-cell assembly are prepared as follows: the Li prepared in Example 1 4 Ti 5 o 12 / TiN composite electrode material, conductive carbon black, and binder ar...

Embodiment 2

[0034] According to urea: Li 4 Ti 5 o 12 0.74 g of urea was added at a mass ratio of 3%, ultrasonically mixed in an anhydrous ethanol medium for 1 h, and then placed in a vacuum drying oven at 100° C. for 8 h. After drying in an atmosphere furnace in N 2 Under a protective atmosphere, the temperature was raised to 850°C at a rate of 5°C / min for 30 minutes, and then cooled with the furnace. The resulting product is Li 4 Ti 5 o 12 / TiN composite electrode material.

[0035] The electrochemical performance test is the same as in Example 1.

[0036] The Li prepared by embodiment 2 method and proportioning 4 Ti 5 o 12 The / TiN composite electrode material has a gram capacity of 160.4mAh / g at 0.2C charge and discharge current, 159.3mAh / g at 0.5C charge and discharge current, and 130mAh / g at 3C charge and discharge current. When charging and discharging at 1C, the capacity retention rate of the material for 100 cycles is ≥94%.

Embodiment 3

[0038] According to urea: Li 4 Ti 5 o 12 2.5 g of urea was added at a mass ratio of 10%, ball milled and mixed in an acetone medium for 2 h, and then dried in a vacuum oven at 120° C. for 8 h. After drying in an atmosphere furnace in N 2 Under a protective atmosphere, the temperature was raised to 850°C at a rate of 3°C / min and kept for 10 minutes, and then cooled with the furnace. The resulting product is Li 4 Ti 5 o 12 / TiN composite electrode material.

[0039] The electrochemical performance test is the same as in Example 1.

[0040] The Li prepared by embodiment 3 method and proportioning 4 Ti 5 o 12 The / TiN composite electrode material has a gram capacity of 159.5mAh / g at 0.2C charge and discharge current, 158.1mAh / g at 0.5C charge and discharge current, and 125mAh / g at 3C charge and discharge current. When charging and discharging at 1C, the capacity retention rate of the material for 100 cycles is ≥92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com