Lithium iron phosphate composite cathode material and preparation method thereof

A composite positive electrode material, lithium iron phosphate technology, applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problem of no improvement in the migration and diffusion of lithium ions, cannot meet the needs of power batteries, and hinder the migration and diffusion of lithium ions To achieve the effect of shortening the diffusion path of lithium ions, improving the high-rate charge-discharge capability, and improving the performance of high-rate charge-discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

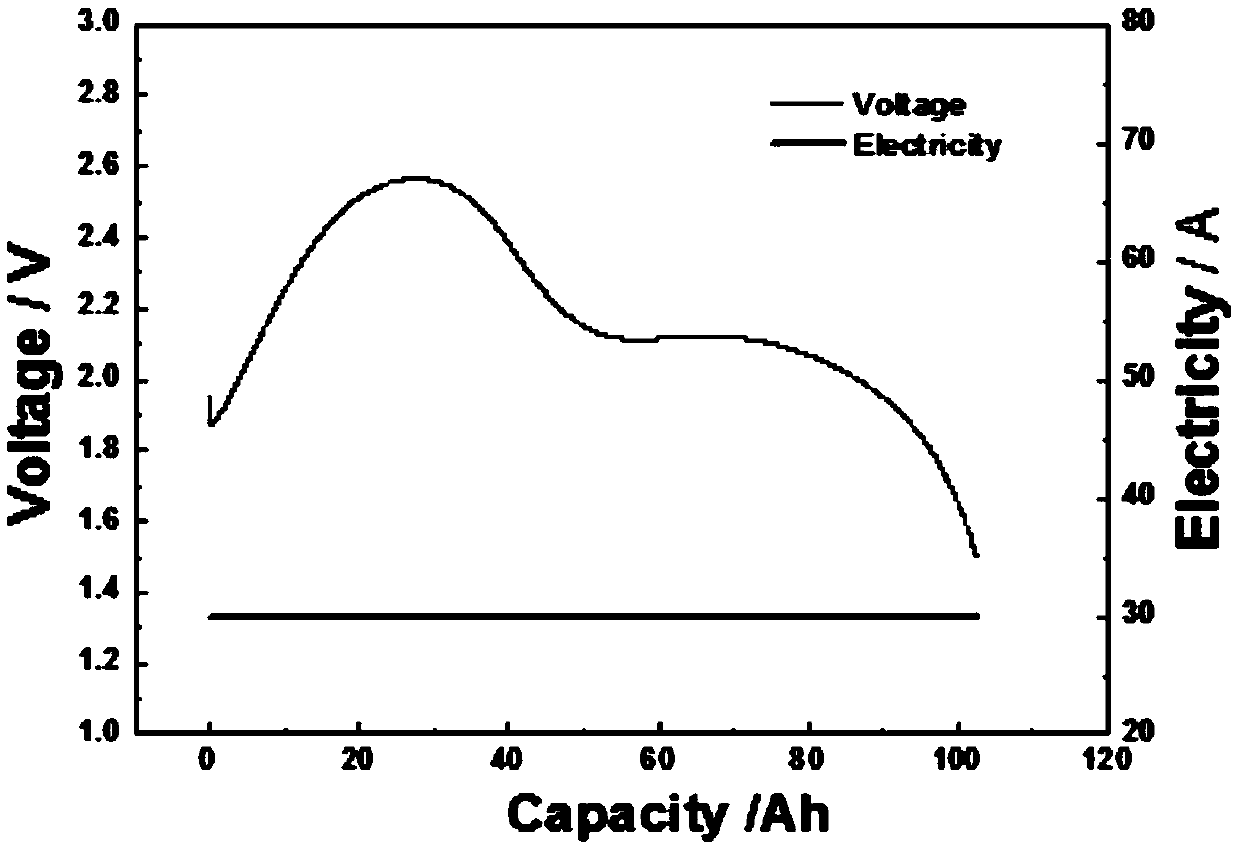

Image

Examples

Embodiment 1

[0042] A lithium iron phosphate composite positive electrode material is prepared by the following steps:

[0043] Step S1: First, weigh 143.86g of ferrous oxalate and 103.93g of lithium dihydrogen phosphate as raw materials according to the molar ratio of Fe:Li:P = 1:1:1, and mix them by ball milling in ethanol medium 4h, dried at 80°C, cooled naturally, continued ball milling for 2h to mix evenly, then heated at 400°C for 12h in an Ar gas atmosphere furnace, and obtained lithium iron phosphate precursor powder after natural cooling.

[0044] Step S2: Use ultrasonic-assisted Hummers method to prepare graphene oxide, then mix and grind melamine and graphene oxide powder according to the mass ratio of 1:7, then heat in an Ar gas atmosphere furnace at 800°C for 6 hours, and cool naturally to obtain N-doped The n-type graphene dopant body, wherein, the N doping amount is 8% (weight percentage).

[0045]Step S3: Mix the N-doped n-type graphene dopant with the lithium iron phospha...

Embodiment 2

[0048] A lithium iron phosphate composite positive electrode material is prepared by the following steps:

[0049] First ferrous citrate, lithium carbonate, diammonium hydrogen phosphate are according to Fe:Li:P mol ratio is 1:1.02:1 each takes by weighing raw material ferrous citrate 246g, lithium carbonate 37.68g, diammonium hydrogen phosphate 132.06g, Ball milled and mixed in ethanol medium for 4 hours, dried at 80°C, cooled naturally, continued ball milled for 2 hours to mix evenly, then heated at 500°C for 10 hours in an Ar gas atmosphere furnace, and cooled naturally to obtain lithium iron phosphate precursor powder.

[0050] Mix and grind benzenediboronic acid and graphene oxide powder according to the mass ratio of 9:4, heat in an Ar gas atmosphere furnace at 600°C for 8 hours, and cool naturally to obtain a B-doped p-type graphene dopant, wherein, B The doping amount is 9% (weight percentage).

[0051] The B-doped p-type graphene dopant and the lithium iron phosphate...

Embodiment 3

[0054] A lithium iron phosphate composite positive electrode material is prepared by the following steps:

[0055] First ferrous oxalate, lithium carbonate, ammonium dihydrogen phosphate according to the mol ratio of Fe:Li:P is 1:1.05:1 and each takes by weighing raw material ferrous oxalate 143.86g, lithium carbonate 38.79g, ammonium dihydrogen phosphate 115.03g, The three were ball milled and mixed in an ethanol medium for 4 hours, dried at 80°C, cooled naturally, continued to be ball milled for 2 hours to mix evenly, and then heated in an Ar gas atmosphere furnace at 600°C for 8 hours, and cooled naturally to obtain a lithium iron phosphate precursor powder.

[0056] Red phosphorus and graphene oxide powder were mixed and ground at a mass ratio of 1:9, then heated at 700°C for 7 hours in an Ar gas atmosphere furnace, and cooled naturally to obtain a P-doped n-type graphene dopant, wherein P-doped Impurity is 10% (weight percentage).

[0057] The P-doped n-type graphene dop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com