Pressure sensitive material used for flexible touch sensation sensor and preparation method thereof

A tactile sensor and sensitive material technology, applied in the direction of instruments, measuring force, measuring devices, etc., can solve the problems that materials cannot have both tactile sensing function and flexibility, cannot be applied to tactile sensor arrays, and have high requirements on array structure, and achieve good Pressure-sensitive properties, improved tactile sensing capabilities, cost-reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add nano-SiO with carbon black and silicone rubber compound system 2 , According to the following proportions by weight:

[0036] One-component room temperature curing liquid silicone rubber RTV GD401: 100 parts;

[0037] Conductive carbon black ECP-CB-1 with an average particle size of 30-40nm and a resistivity of 0.2-0.6Ω·cm: 6 parts;

[0038] Nano SiO with a particle size of 15-20nm 2 : 2 copies;

[0039] Density 650~750kg / m 3 , Distilled naphtha as a dispersant: 8 parts.

[0040] making process:

[0041] Under normal temperature and pressure, the conductive carbon black ECP-CB-1 and the dispersant are ultrasonically dispersed with the FS-150 ultrasonic processor for 30-40 minutes to obtain a mixed solution A; the nano-SiO 2 The powder is added to mixed solution A, and after ultrasonic dispersion for 30-40 minutes, mixed solution B is obtained; mixed solution B is added to liquid silicone rubber, and mixed solution C is obtained by ultrasonic dispersion for 20-30 minutes...

Embodiment 2

[0044] Add nano-SiO with carbon black and silicone rubber compound system 2 , According to the following proportions by weight:

[0045] One-component room temperature curing liquid silicone rubber RTV GD401: 100 parts,

[0046] Conductive carbon black ECP-CB-1 with an average particle size of 30-40nm and a resistivity of 0.2-0.6Ω·cm: 8 parts

[0047] Nano SiO with a particle size of 15-20nm 2 :3 copies

[0048] Density 650~750kg / m 3 , Distilled naphtha as a dispersant: 8.5 parts.

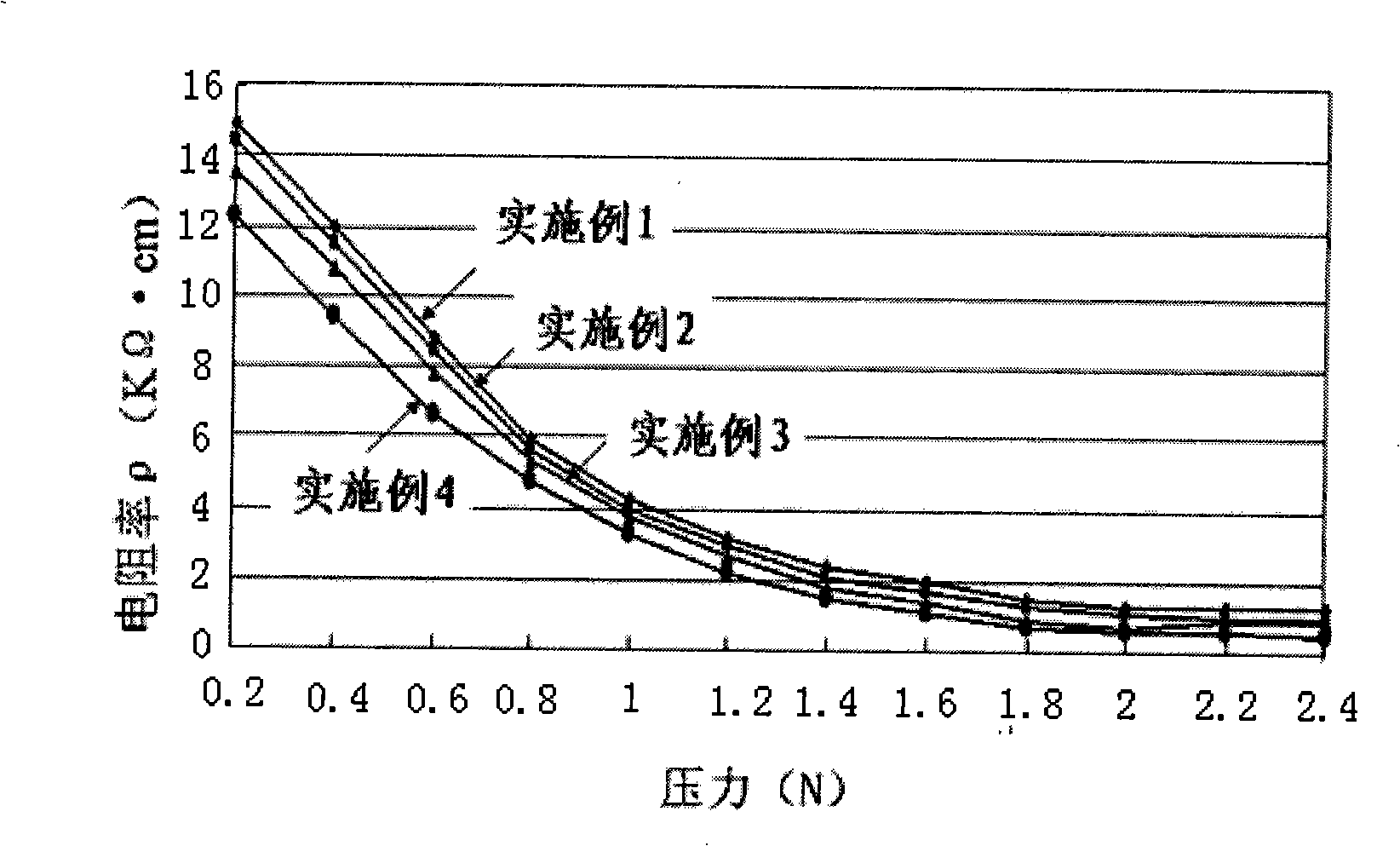

[0049] The preparation process is the same as in Example 1. The pressure sensitive characteristic test of the obtained pressure sensitive material is carried out, and the test results are as follows: figure 1 Example 2 characteristic curve shown.

Embodiment 3

[0051] Add nano-SiO with carbon black and silicone rubber compound system 2 , The material components are proportioned according to the following parts by weight:

[0052] One-component room temperature curing liquid silicone rubber RTV GD401: 100 parts;

[0053] Conductive carbon black ECP-CB-1 with an average particle size of 30-40nm and a resistivity of 0.2-0.6Ω·cm: 9 parts

[0054] Nano SiO with a particle size of 15-20nm 2 :4 parts

[0055] Density 650~750kg / m 3, Distilled naphtha as a dispersant: 9 parts.

[0056] The preparation process is the same as in Example 1. The pressure sensitive characteristic test of the obtained pressure sensitive material is carried out, and the test results are as follows: figure 1 Example 3 characteristic curve shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com