Preparation method of silicon-based anode material for lithium ion battery

A silicon-based negative electrode material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of limited battery cycle and rate performance, and achieve improved ion permeability, rate performance, and particle size. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

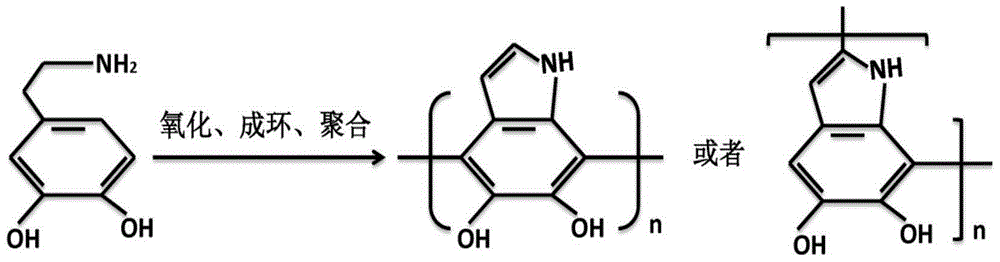

Method used

Image

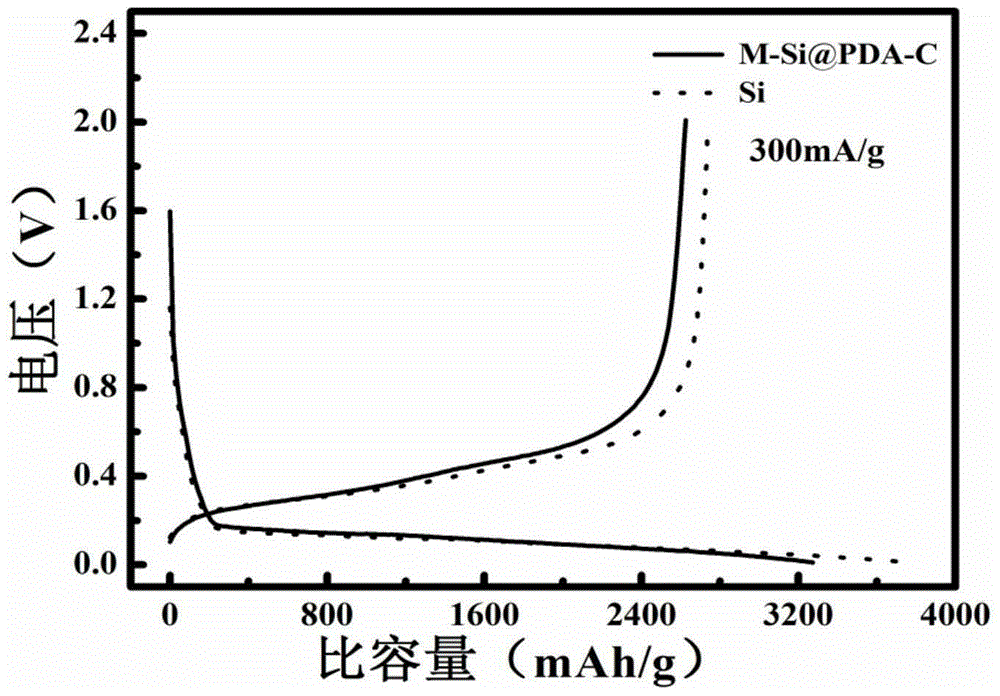

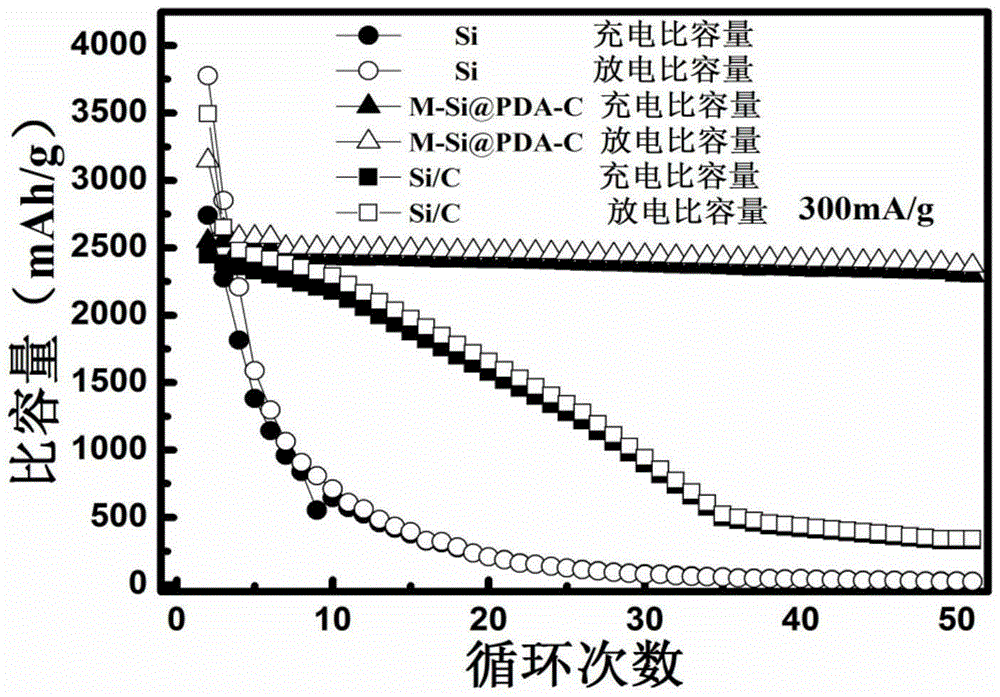

Examples

Embodiment 1

[0032] The preparation method of the lithium-ion battery silicon-based negative electrode material of the present embodiment comprises the following steps:

[0033] (1) Add 0.3g of nano-alumina to 100mL of ethanol aqueous solution (volume fraction of ethanol is 50%) for stirring and dispersing, add 20mL of concentrated ammonia water to the suspension, continue stirring until the mixture is uniform, and then add 4mL of orthosilicone dropwise A mixed solution of ethyl acetate and 16 mL of ethanol was stirred continuously during the dropwise addition until the reaction was completed, and the resulting product was subsequently centrifuged, and the solid product obtained after centrifugation was washed with deionized water and dried under vacuum to obtain Al 2 o 3 SiO 2 solid;

[0034] (2) Add 0.8gAl 2 o 3 SiO 2 The solid is ground and mixed with 1g of magnesium powder evenly, and placed in a tube furnace to heat up to 650°C for 3 hours under an argon protective atmosphere to ...

Embodiment 2

[0039] The preparation method of the lithium-ion battery silicon-based negative electrode material of the present embodiment comprises the following steps:

[0040] (1) Add 0.3g of nano-alumina to 100mL of ethanol aqueous solution (volume fraction of ethanol is 50%) for stirring and dispersing, add 20mL of concentrated ammonia water to the suspension, continue to stir until the mixture is uniform, and then add 3mL of orthosilicone dropwise The mixed solution of ethyl acetate and 12mL ethanol was continuously stirred during the dropwise addition until the reaction was completed, and the resulting product was then centrifuged, and the solid product obtained after centrifugation was washed with deionized water and dried under vacuum to obtain Al 2 o 3 SiO 2 solid;

[0041] (2) Add 0.9gAl 2 o 3 SiO 2 The solid is ground and mixed with 1g of magnesium powder evenly, and placed in a tube furnace to heat up to 650°C for 3 hours under an argon protective atmosphere to obtain a so...

Embodiment 3

[0047] The preparation method of the lithium-ion battery silicon-based negative electrode material of the present embodiment comprises the following steps:

[0048] (1) Add 0.2g of nano-alumina to 100mL of ethanol aqueous solution (volume fraction of ethanol is 50%) for stirring and dispersing, add 20mL of concentrated ammonia water to the suspension, continue stirring until the mixture is uniform, and then add 2mL of orthosilicone dropwise A mixed solution of ethyl acetate and 10 mL of ethanol was continuously stirred during the dropwise addition until the reaction was completed, and the resulting product was subsequently centrifuged, and the solid product obtained after centrifugation was washed with deionized water and dried under vacuum to obtain Al 2 o 3 SiO 2 solid;

[0049] (2) Add 0.6gAl 2 o 3 SiO 2 The solid and 0.7g of magnesium powder were ground and mixed evenly, and placed in a tube furnace to heat up to 650°C for 3 hours under an argon protective atmosphere ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com