Underfill adhesive and preparation method thereof

An underfill, epoxy resin technology, applied in the direction of adhesive, epoxy resin, adhesive type, etc., can solve the problem of poor thermal conductivity, achieve high thermal conductivity and improve thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

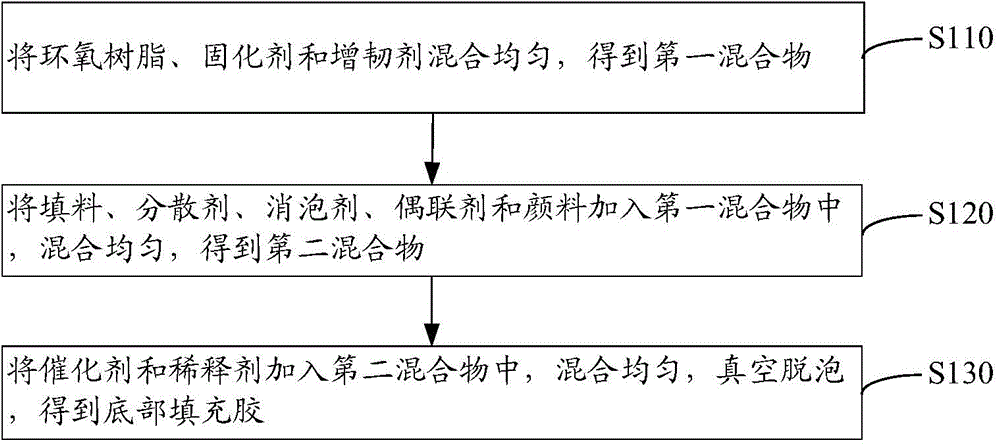

[0052] Further, a method for preparing an underfill glue is provided. see figure 2 , the preparation method of the underfill comprises the following steps:

[0053] Step S110: uniformly mixing the epoxy resin, curing agent and toughening agent to obtain a first mixture.

[0054] In terms of mass percentage, 10-50% of epoxy resin, 2-20% of curing agent and 1-15% of toughening agent are added into a high-speed shear mixing tank and mixed uniformly to obtain the first mixture.

[0055] Preferably, the uniform mixing time is 5-30 minutes.

[0056] Step S120: adding fillers, dispersants, defoamers, coupling agents and pigments into the first mixture, and mixing uniformly to obtain a second mixture.

[0057] In terms of mass percentage, add 30-70% of filler, 0.1-3% of dispersant, 0.05%-1% of defoamer, 0.1-1% of coupling agent and 0.1-0.5% of pigment into the above mixture Fill in, mix evenly, obtain the second mixture.

[0058] Preferably, the uniform mixing time is 5-30 minut...

Embodiment 1

[0068] Weigh 10.0g of bisphenol A type epoxy resin E511, 10.0g of curing agent methyl hexahydrophthalic anhydride, and 1.0g of toughening agent carboxyl-terminated nitrile rubber (CTBN) and add them into a high-speed shear mixing tank and mix evenly for 5min, then weigh Take spherical nano-SiO with a particle size of 800nm 2 Filler 30.0g, spherical nano-Al with a particle size of 200nm 2 o 3 Put 38.15g of filler, 0.1g of fatty acid dispersant, 0.05g of polysiloxane defoamer, 0.1g of silane coupling agent and 0.5g of pigment into the mixing tank and mix evenly for 5min. Next, 0.1 g of the catalyst 2-ethyl-4-methylimidazole and 10.0 g of the diluent o-cresyl glycidyl ether were put into the mixing tank and mixed uniformly for 5 minutes, and vacuum degassed for 5 min to obtain the underfill rubber.

[0069] The component distribution ratio of the obtained underfill is shown in Table 1 below:

[0070] Table 1

[0071] components mass percentage filler 68.15% ...

Embodiment 2

[0074] Weigh bisphenol F type epoxy resin EPIKOTE 86220.0g, alicyclic epoxy resin 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexyl carboxylate 10.0g, curing agent m-phenylenediamine 8.0 g and 2.0 g of toughening agent polysulfide rubber were added to the high-speed shear mixing tank and mixed evenly for 10 minutes, and then weighed spherical SiO with a particle size of 1000 nm 2 Put 20.5g of filler, 33.4g of spherical nano-BN filler with a particle size of 200nm, 0.2g of fatty acid dispersant, 0.10g of polysiloxane defoamer, 0.2g of silane coupling agent and 0.5g of pigment into the mixing tank Mix well for 10min. Next, 0.1 g of the catalyst 2-phenyl-4-methylimidazole and 5.0 g of the diluent neopentyl glycol diglycidyl ether were put into the mixing tank and mixed uniformly for 10 minutes, followed by vacuum defoaming for 5 minutes to obtain the underfill rubber.

[0075] The component distribution ratio of the obtained underfill is shown in Table 2 below:

[0076] Table 2

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com