Titanium carbonitride blast furnace protecting agent and preparation method thereof

A technology for titanium carbonitride and blast furnace protection, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of increased slag volume, coke energy consumption, titanium dioxide waste, etc., and achieves the effect of protecting the hearth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A titanium carbonitride blast furnace protection agent, which consists of the following components in proportion by weight:

[0019] Calcium carbonitride Ti(C,N) 50~74%,

[0020] Composition CaO+MgO+SiO 2 +AL 2 o 3 17-40%,

[0021] Free carbon greater than 1%,

[0022] Total iron Tfe greater than 3%,

[0023] Ti oxide is less than 6%.

[0024] Free carbon is greater than 1%, no on-line requirements, it is determined according to customer requirements, total iron content Tfe is greater than 3%, there is no on-line requirement, it is determined according to customer requirements, titanium oxide is less than 6%, no off-line, Determined according to customer requirements.

[0025] A preparation method of titanium carbonitride blast furnace protection agent:

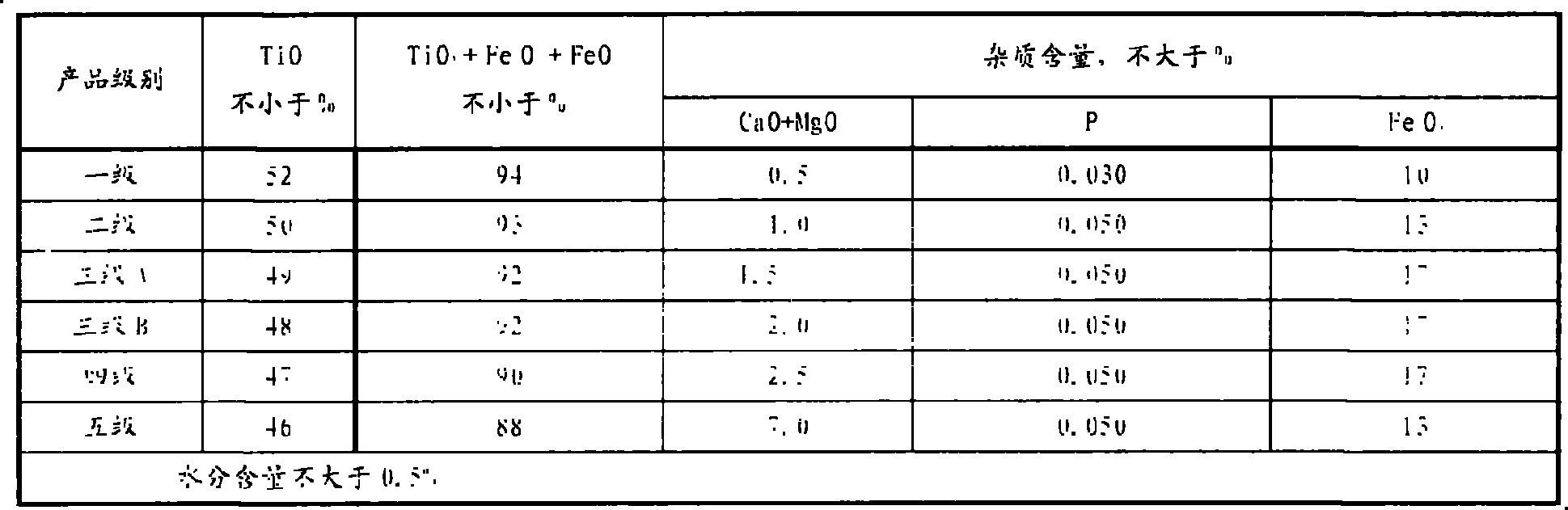

[0026] (1) According to industry standards, select titanium concentrates with low silicon, low sulfur, low phosphorus, low calcium magnesium, and high titanium dioxide, with an average particle size of 150 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com