Preparation process of harmonic reducer flexible gear

A harmonic reducer and preparation technology, which is applied in the direction of manufacturing tools, metal material coating technology, heat treatment equipment, etc., can solve the problems that cannot meet the application needs of the chemical industry, low fatigue strength, low surface hardness, etc., and achieve improvement Overall rigidity and fatigue resistance, high fatigue strength, and the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

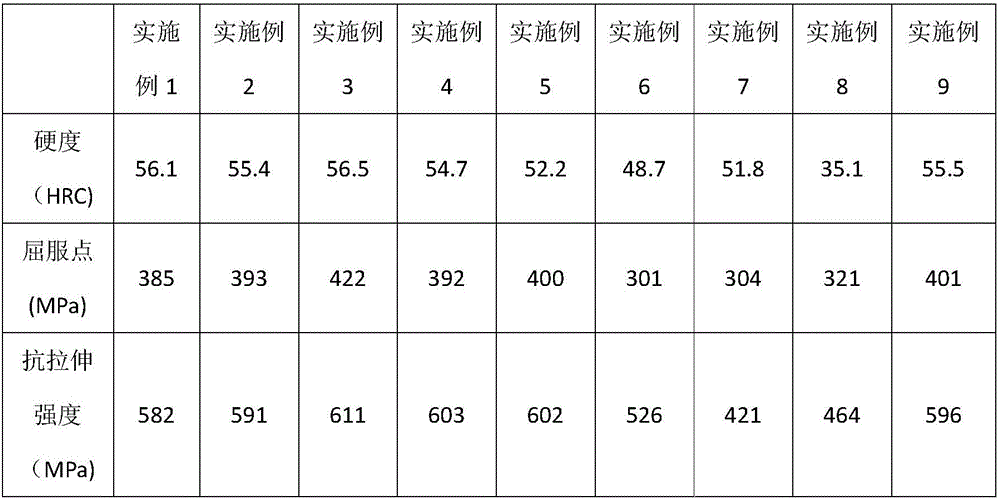

Examples

Embodiment 1

[0016] (1) Take 84 parts of low-carbon molten steel water atomized iron powder with a particle size of less than 200 meshes, 6 parts of graphene powder, 3 parts of nano-silicon carbide powder, 6 parts of polyamideimide powder and 1 part of coupling agent powder. Into the mixer, 100rpm mixing 8h, wherein the coupling agent is the mixture of chromium complex coupling agent and monoalkoxy titanate coupling agent, the chromium complex coupling agent and monoalkoxytitanium The ratio of ester coupling agent is 1:3; (2) put the uniformly mixed powder in step (1) into a vacuum ball mill for ball milling, the ball to material ratio is 25:1, the ball milling speed is 50rpm, the ball milling time is 6h, the ball milling process In the process, the cooling water circulation control system controls the temperature of the ball mill to be lower than 80°C; (3) Put the powder ground in step (2) into the crucible of the vacuum shell melting furnace, and vacuumize the inner tank of the vacuum she...

Embodiment 2

[0018] (1) Take 81 parts of low-carbon molten steel water atomized iron powder with a particle size of less than 200 meshes, 7 parts of graphene powder, 3.5 parts of nano-silicon carbide powder, 7 parts of polyamideimide powder and 1.5 parts of coupling agent powder. Into the stirrer, 80rpm mixing 10h, wherein the coupling agent is the mixture of chromium complex coupling agent and monoalkoxy titanate coupling agent, the chromium complex coupling agent and monoalkoxytitanium The ratio of ester coupling agent is 1:3; (2) put the uniformly mixed powder in step (1) into a vacuum ball mill for ball milling, the ball to material ratio is 26:1, the ball milling speed is 45rpm, the ball milling time is 6h, the ball milling process In the process, the cooling water circulation control system controls the temperature of the ball mill to be lower than 80°C; (3) Put the powder ground in step (2) into the crucible of the vacuum shell melting furnace, and vacuumize the inner tank of the vac...

Embodiment 3

[0020] (1) Take 78 parts of low-carbon molten steel water atomized iron powder with a particle size of less than 200 meshes, 8 parts of graphene powder, 4 parts of nano-silicon carbide powder, 8 parts of polyamideimide powder and 2 parts of coupling agent powder. Into the mixer, 100rpm mixing 6h, wherein the coupling agent is the mixture of chromium complex coupling agent and monoalkoxy titanate coupling agent, the chromium complex coupling agent and monoalkoxytitanium The ratio of ester coupling agent is 1:3; (2) put the uniformly mixed powder in step (1) into a vacuum ball mill for ball milling, the ball to material ratio is 25:1, the ball milling speed is 45rpm, the ball milling time is 6h, the ball milling process In the process, the cooling water circulation control system controls the temperature of the ball mill to be lower than 80°C; (3) Put the powder ground in step (2) into the crucible of the vacuum shell melting furnace, and vacuumize the inner tank of the vacuum sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com