Heat treatment process of metal workpiece

A metal workpiece and process technology, which is applied in the field of heat treatment technology to improve the fatigue pitting wear resistance of workpieces, can solve problems such as gear fatigue pitting wear and other problems, and achieve the effect of improving strength and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

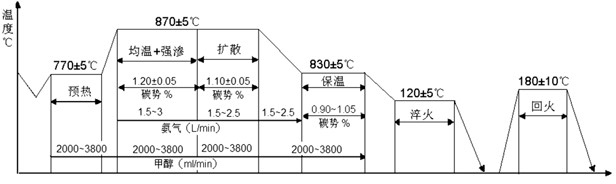

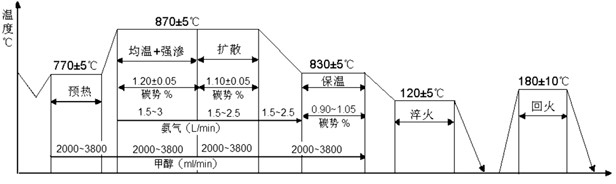

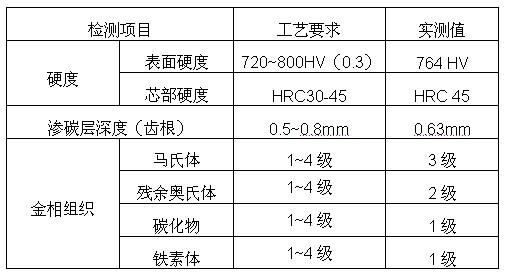

[0031] Under a protective atmosphere, preheat the gear at 770±5°C for 25±5 minutes, and feed methanol while preheating, and the flow rate of methanol is 3.8L / min.

[0032] After preheating, raise the temperature to 870±5°C at the fastest speed, and pass ammonia gas at this temperature, and the flow rate of ammonia gas is 2.5L / min. Methane is introduced to adjust the carbon potential to 1.23%, and the intensive infiltration stage of carbonitriding is carried out.

[0033] After 135 minutes, it enters the diffusion stage, the nitrogen flow rate is adjusted to 1.5L / min, and the carbon potential is adjusted to 1.07%.

[0034] After 50 minutes, lower the temperature to 830±5°C as soon as possible, keep warm at this temperature, stop the introduction of ammonia gas, and adjust the carbon potential to 0.95%.

[0035] Heat preservation for 35 minutes, oil cooling and quenching, the quenching temperature is 120±5°C, and the time is 30 minutes.

[0036] After the quenching is complete...

Embodiment 2

[0038] Under a protective atmosphere, preheat the gear at 770±5°C for 25 minutes, and feed methanol while preheating, and the flow rate of methanol is 3.8L / min.

[0039] After preheating, raise the temperature to 870±5°C at the fastest speed, and pass ammonia gas at this temperature, and the flow rate of ammonia gas is 2.5L / min. The carbon potential is adjusted to 1.18% by introducing methane, and the intensive infiltration stage of carbonitriding is carried out.

[0040] After 125 minutes, it enters the diffusion stage, the nitrogen flow rate is adjusted to 1.5L / min, and the carbon potential is adjusted to 1.08%.

[0041] After 45 minutes, lower the temperature to 830±5°C as soon as possible, and keep it warm at this temperature. At the same time, stop the introduction of ammonia gas, and adjust the carbon potential to 1.02%.

[0042] Heat preservation for 45 minutes, oil cooling and quenching, the quenching temperature is 120±5°C, and the time is 30 minutes.

[0043] After...

Embodiment 3

[0045] Under a protective atmosphere, preheat the gear at 770±5°C for 25 minutes, and feed methanol while preheating, and the flow rate of methanol is 3.8L / min.

[0046] After preheating, raise the temperature to 870±5°C at the fastest speed, and stabilize the temperature after a certain period of time (such as 35 minutes). At this temperature, ammonia gas is introduced, and the flow rate of ammonia gas is 2.5L / min. Methane is introduced to adjust the carbon potential to 1.20%, and the intensive infiltration stage of carbonitriding is carried out.

[0047] After 130 minutes, it enters the diffusion stage, the nitrogen flow rate is adjusted to 1.5L / min, and the carbon potential is adjusted to 1.10%.

[0048] After 45 minutes, lower the temperature to 830±5°C as soon as possible, and keep it warm at this temperature. At the same time, stop the introduction of ammonia gas, and adjust the carbon potential to 0.98%.

[0049] Heat preservation for 45 minutes, oil cooling and quench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com