Washer

A washing machine and washing tub technology, applied in the field of washing machines, can solve the problems of difficult overhaul and maintenance, cluttered washing machine pipelines, and high failure rate, and achieve the effects of improving reliability, optimizing flow path layout and control mode, and reducing the risk of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

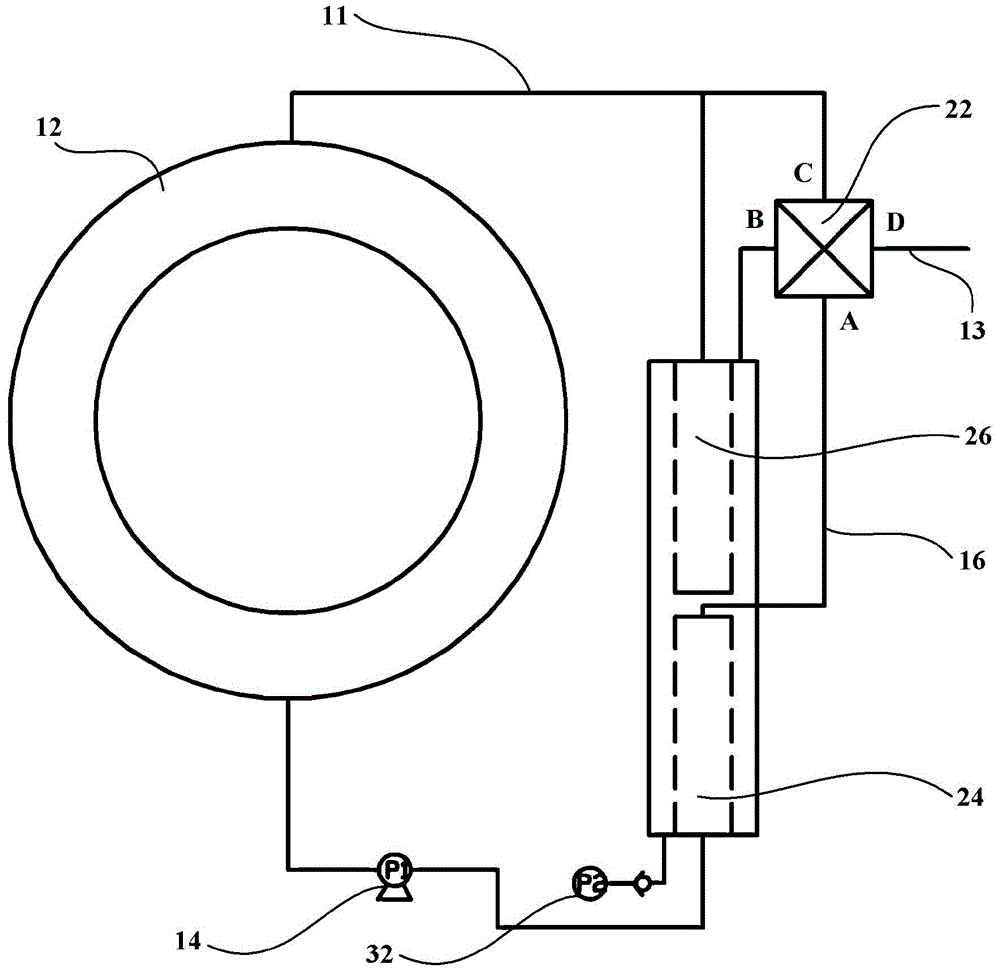

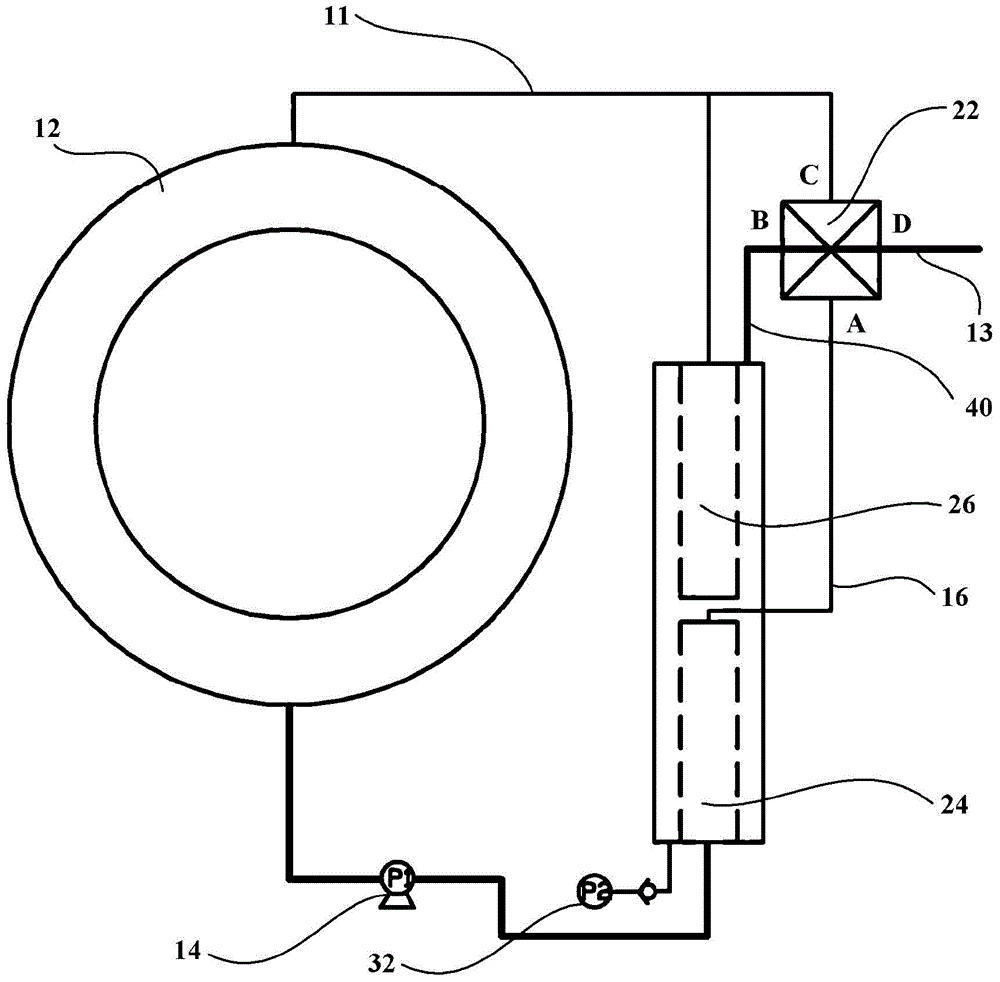

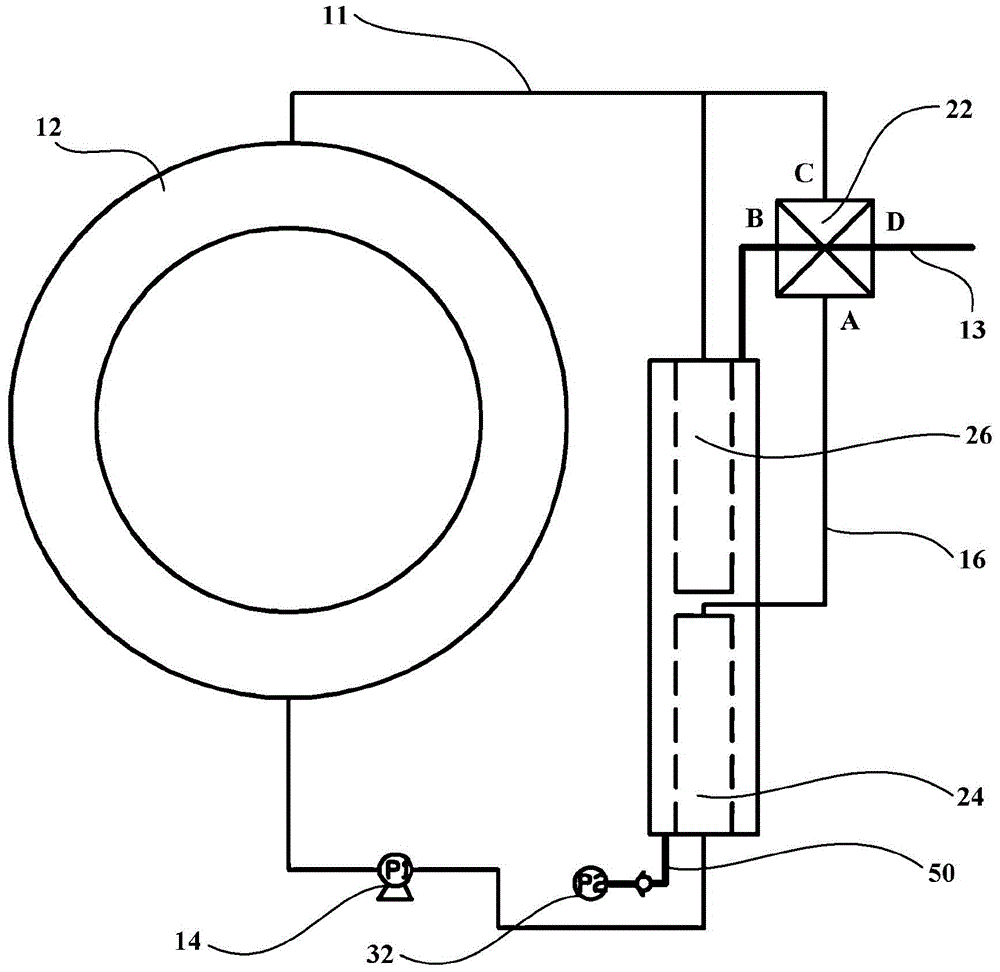

[0049] figure 1 is a schematic schematic diagram of a washing machine according to an embodiment of the present invention. The washing machine may include a washing tub 12 , a drain pump 14 , a filter assembly and a flow switching device 22 . The washing tub 12 is generally composed of an outer tub and an inner tub that can rotate in the outer tub. The bottom of the washing tub 12 is provided with a drain port, and the drain port communicates with the filter assembly via a drain pump 14 through a pipeline. According to needs, for example, in the washing program or rinsing program of the washing machine, the water in the washing tub 12 can be pumped out, transported to the filter assembly for filtering, and then circulated back to the washing tub 12 for reuse.

[0050] exist figure 1 In the illustrated embodiment, the filter assembly can be composed of a coarse filter 24 and a fine filter 26 located downstream of the coarse filter 24 (those skilled in the art should understa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com