Ultrahigh-flux nanofiber filtering membrane and preparation method thereof

A nanofiber and filtration membrane technology, applied in the field of ultra-high flux nanofiber filtration membrane and its preparation, can solve the problem of small diameter of spinning fiber, poor mechanical properties of nanofiber filtration membrane, flux loss of nanofiber filtration membrane, etc. problems, to achieve the effect of improving mechanical properties, improving hydrophilic properties, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

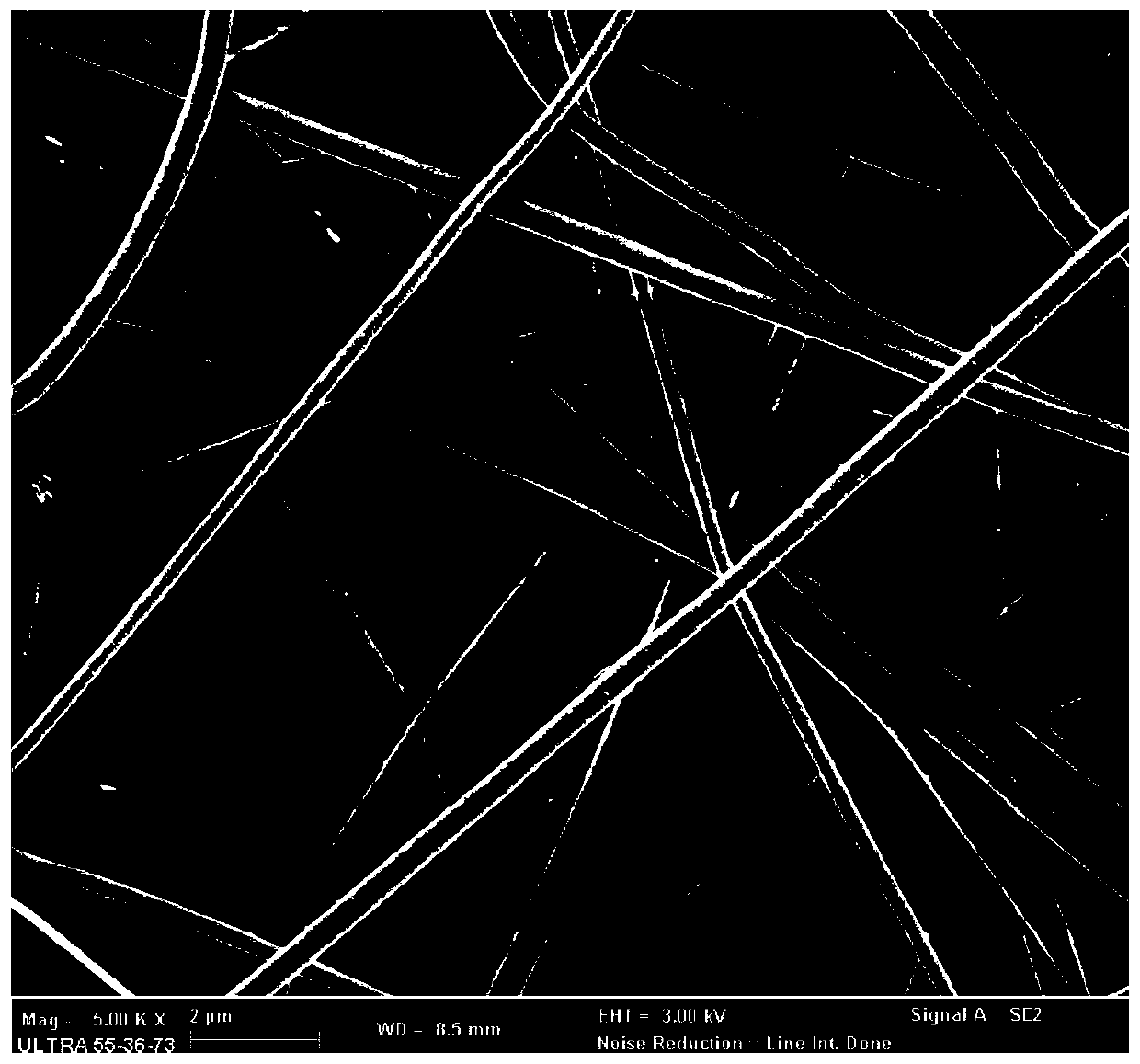

Image

Examples

Embodiment 1

[0029] The fiber-forming polymer of the nanofiber filter membrane in this embodiment is polyvinylidene fluoride; the specific preparation steps are as follows:

[0030] Preparation of additive mixture:

[0031] According to the mass ratio of 3:2:1, take anhydrous calcium chloride, anhydrous magnesium chloride and anhydrous sodium chloride respectively, stir and mix them evenly and add them to N,N-dimethylformamide. Under the ultrasonic condition of 25kHz, carry out high-speed rotation dissolution of 2400-3000r / min until the solid is completely dissolved to obtain an additive mixture. In the additive mixture, anhydrous calcium chloride, anhydrous magnesium chloride and anhydrous sodium chloride The total mass fraction is 1%.

[0032] Spinning solution preparation:

[0033] (1) Measure N,N-dimethylformamide and N,N-dimethylacetamide respectively according to the volume ratio of 8:2, stir and mix them evenly to obtain a formacetamide mixed solution.

[0034] (2) According to t...

Embodiment 2

[0043] The fiber-forming polymer of the nanofiber filtration membrane in this embodiment is polyethersulfone; the specific preparation steps are as follows:

[0044]Preparation of additive mixture:

[0045] According to the mass ratio of 3:2:1, take anhydrous calcium chloride, anhydrous magnesium chloride and anhydrous sodium chloride respectively, stir and mix them evenly and add them to N,N-dimethylformamide. Under the ultrasonic condition of 25kHz, carry out high-speed rotation dissolution of 2400-3000r / min until the solid is completely dissolved to obtain an additive mixture. In the additive mixture, anhydrous calcium chloride, anhydrous magnesium chloride and anhydrous sodium chloride The total mass fraction is 1.5%.

[0046] Spinning solution preparation:

[0047] (1) According to the volume ratio of 7.9:2.1, N,N-dimethylformamide and N,N-dimethylacetamide were respectively measured, stirred and mixed evenly to obtain a formacetamide mixed solution.

[0048] (2) Accor...

Embodiment 3

[0056] The fiber-forming polymer of the nanofiber filter membrane of this embodiment is polyacrylonitrile; the specific preparation steps are as follows:

[0057] Preparation of additive mixture:

[0058] According to the mass ratio of 3:2:1, take anhydrous calcium chloride, anhydrous magnesium chloride and anhydrous sodium chloride respectively, stir and mix them evenly and add them to N,N-dimethylformamide. Under the ultrasonic condition of 25kHz, carry out high-speed rotation dissolution of 2400-3000r / min until the solid is completely dissolved to obtain an additive mixture. In the additive mixture, anhydrous calcium chloride, anhydrous magnesium chloride and anhydrous sodium chloride The total mass fraction is 2%.

[0059] Spinning solution preparation:

[0060] (1) Measure N,N-dimethylformamide and N,N-dimethylacetamide respectively according to the volume ratio of 7:3, stir and mix them evenly to obtain a formacetamide mixed solution.

[0061] (2) According to the vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com